Degree of Freedom:

Parametric workflows for complex geometry at the new Drammen City Bridge

By Tomas Jakobsen

BuildingPoint Scandinavia

The city bridge in Drammen has been an important connection across the river since the first bridge was built here in 1813. The new bridge, which opened in 2025, replaces the structure from the 1930s and is a key part of the city’s transport network.

The project was architecturally ambitious and technically complex, with a curved alignment and strict design requirements. While Drammen kommune had the overall project management, engineering firm Degree of Freedom was responsible for coordinating engineering design of the river span, and worked to develop a solution that was both buildable and flexible throughout the process.

In this article, we hear from Adrián Enríquez and Birger Opgård in Degree of Freedom about the project and how early decisions made the digital modeling both manageable and adaptable.

Early modeling decisions shaped the project

Design work began in 2019, with early engineering progressing through 2020. At the time, 3D BIM workflows were well established in Norwegian infrastructure, but most projects were still delivered with full drawing sets.

For Degree of Freedom, this project marked a clear step forward: it was the first time Rhino 3D and Grasshopper were used as core tools from concept to construction, in conjunction with Tekla Structures.

“When I saw the geometry, I thought: we need something on top of Tekla,” said Adrián Enríquez, BIM lead for the project.

The bridge’s curved alignment and twisting geometry meant that traditional BIM tools couldn’t manage the surface logic efficiently — or allow for the changes that were bound to come. The team developed a fully parametric model in Rhino, using the alignment as a control input.

This became crucial when the rail alignment at the train station was raised by 50 cm — forcing changes to the bridge geometry without moving the endpoints. Because of the parametric setup, the team could update key elements without starting from scratch.

“

When I saw the geometry, I thought: We need something on top of Tekla…

— Adrián Enríquez, Degree of Freedom

Steel modeling and model-based fabrication

While Rhino handled geometry development, steel components were exported to Tekla Structures, where detailing and production modeling took place.

Tekla allowed the team to prepare a fully coordinated fabrication model, including all adjustments and tolerances.

“We exported the steel geometry from Rhino, but all the detailing, all the production-level stuff — that was in Tekla,” said Enríquez.

The Tekla model was delivered directly to the steel fabricator in Germany, who used it to produce shop drawing based on the Tekla model and some additional drawings with welding informations and chamfering of plates.

This model-based workflow helped reduce coordination time and supported clearer expectations across teams.

“

We exported the steel geometry from Rhino, but all the detailing, all the production-level stuff — that was in Tekla.

— Adrián Enríquez, Degree of Freedom

Coordinating across scopes

Degree of Freedom was responsible for the river span, while Norconsult handled the adjacent section over the railway. Although working under separate contracts, the two firms coordinated closely.

“Even though we had different scopes, it felt like one design team,” said Birger Opgård from Degree of Freedom.

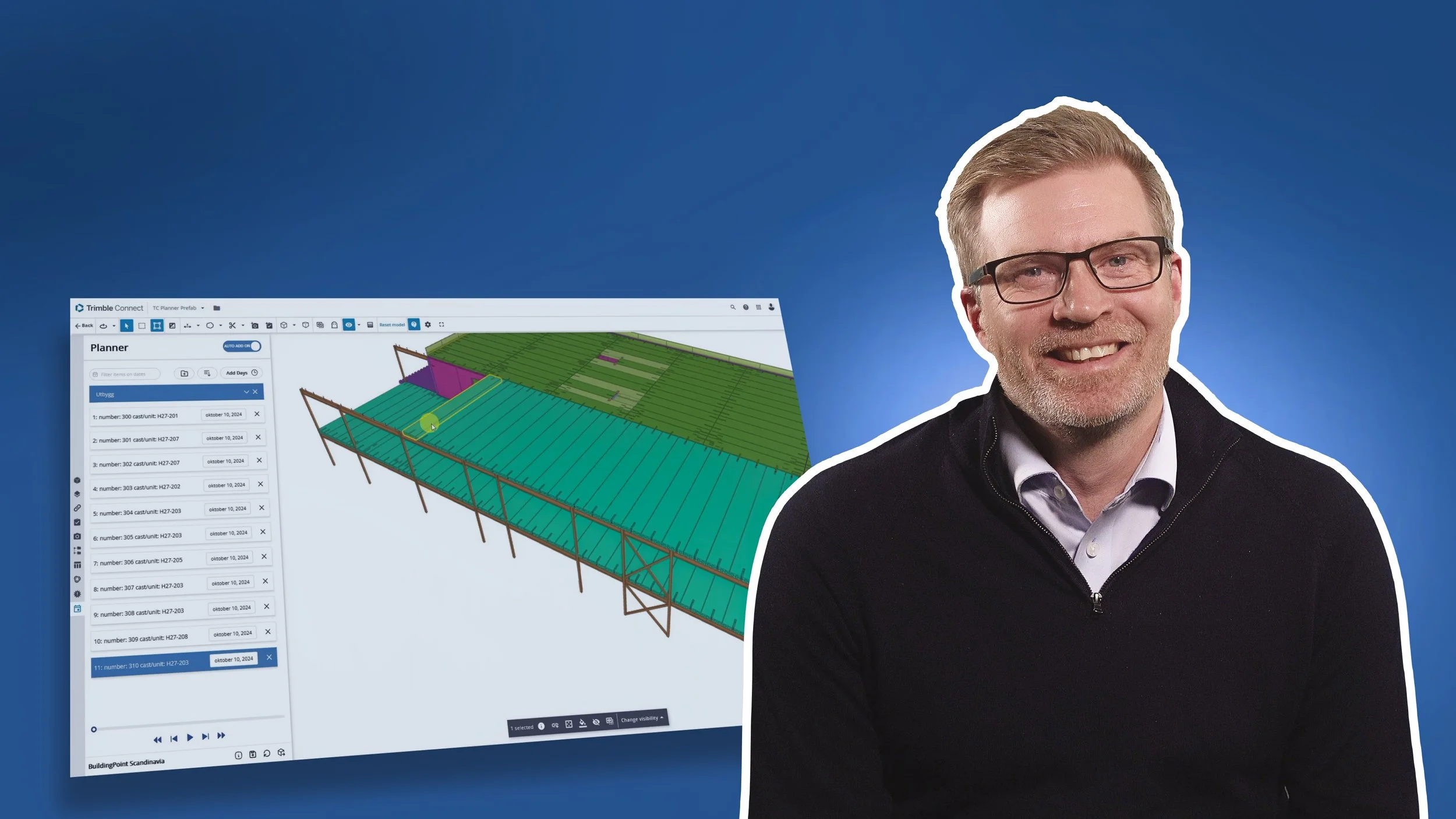

Both firms used Tekla, and models were shared via Trimble Connect, where structural, architectural, and MEP models were regularly exchanged in IFC format. The interface between the spans required tight coordination — not just geometrically, but also in terms of modeling conventions and model handoff.

On site, contractors used a mix of models and 2D drawings, depending on discipline. Bane NOR worked directly from the model. Other teams still relied on drawings for certain elements — a reflection of how projects were typically delivered in 2020.

Degree of Freedom noted that today, most of their new projects are model-first, with drawings playing a secondary role.

“

Using Trimble Connect made it easy and convenient for me, as a project manager, to access technical documentation and 3D models throughout the project.

— Tommy Iversen

Project director in Drammen Kommune.

Trimble Connect FREE E-learning

Check out our comprehensive and free 19-lessons training course!

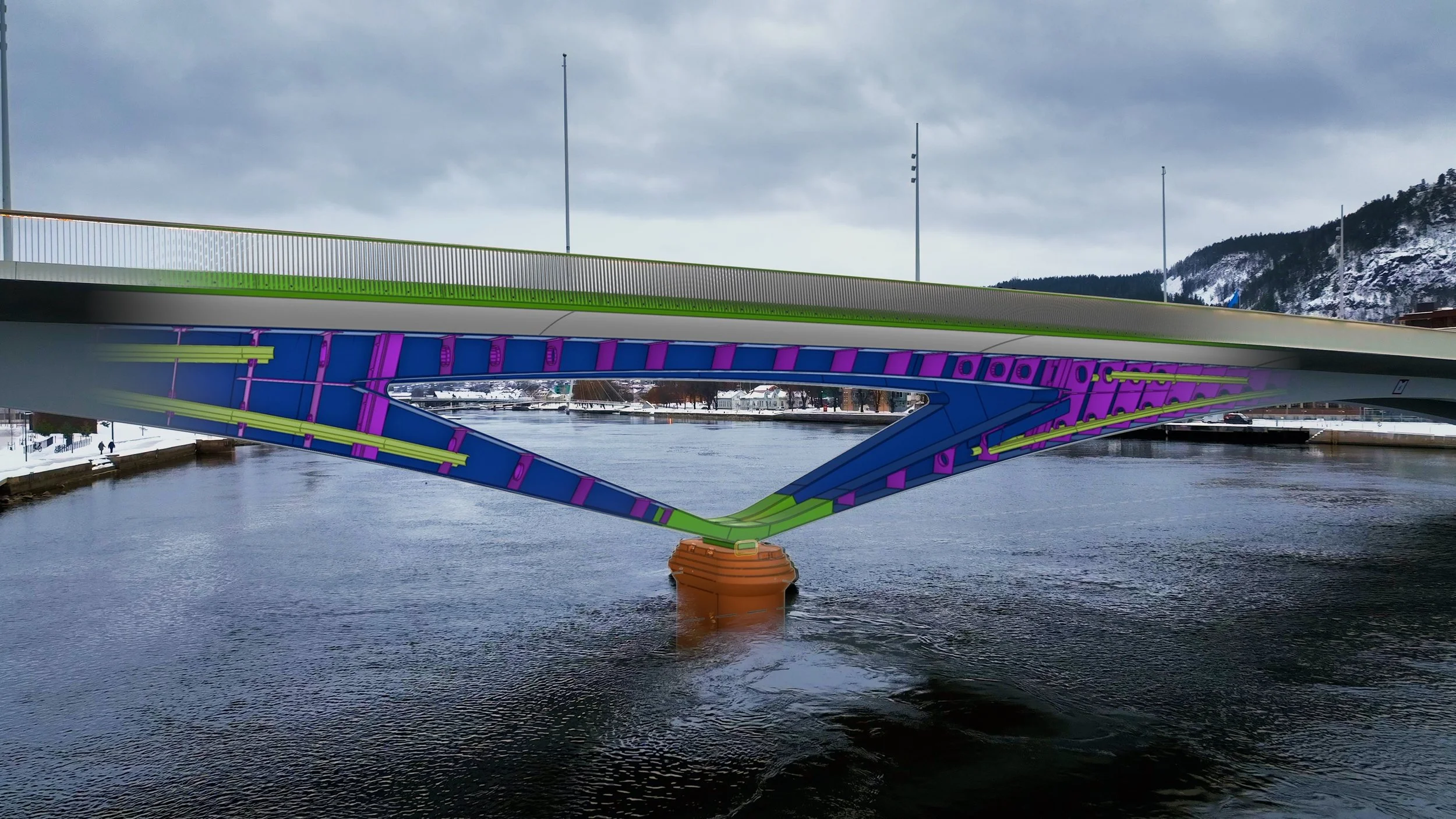

IMAGE: Bearings at axis 8 on the north end of Drammen City Bridge

After reviewing the foundation requirements, the team revised the design at axis 8 to include a spherical bearing with a shear key. This change relieved stress in the structure and simplified the load path — significantly improving structural behavior and coordination.

“The foundation had become huge — almost like a building underwater,” said Opgård. “With the bearing, the whole system became more forgiving.”

This is just one of many examples of how design decisions sometimes have to be made late in a project — and how a robust digital model supports that flexibility.

PHOTO: Drammen City Bridge. Photo by Niklas Hart.

Structural redesign and simplification

One early design challenge came from the original plan to fix both river piers without bearings. This created a coupled structure where the superstructure, substructure, and foundation were fully interdependent — making analysis and detailing more complex.

The foundation design and underwater works were part of Degree of Freedom’s scope, but the engineering was carried out by Norconsult as a subcontractor.

“

The architectural design of the bridge is beautiful. Meeting the architectural vision posed significant challenges for both engineering and fabrication.

The end result is of a high standard, with a smooth box girder shell and a slender concrete bridge deck. The finished structure is visually appealing and impressive.

— Tommy Iversen, Project director in Drammen Kommune.

Fully detailed reinforcement and late-stage changes

The bridge deck is slender — a key part of the architectural intent — but this made reinforcement detailing difficult. The team had to accommodate Ø32 mm longitudinal bars and tightly spaced transverse bars, with little room for tolerances. Mechanical couplers were used to reduce congestion, and bar layouts were optimized to stay within buildable limits.

Instead of relying on symbolic reinforcement or general bar schedules, the team modeled all reinforcement in full detail using Tekla. This gave the contractor and fabricator precise, buildable input — which proved critical when late changes were introduced.

IMAGE: Rebar details in the Drammen City Bridge deck. The highlighteted rebars are Ø32 mm.

A major example was the contractor’s decision to switch to a movable formwork system. This added internal support structures that required reinforcement changes in already congested zones.

“At one point we had to change the reinforcement quite late. In Tekla, we could just do it — we didn’t have to rebuild the whole model,” said Enríquez.

“There were moments when I wasn’t sure it would all fit,” he added. “If we were doing it again, we might go for a slightly thicker deck.”

IMAGE: Rebar details in the Drammen City Bridge deck. The highlighteted rebars are Ø32 mm.

“

At one point we had to change the reinforcement quite late. In Tekla, we could just do it — we didn’t have to rebuild the whole model

— Adrián Enríquez, Degree of Freedom

Parametric tools beyond the structure

The railing — although visually simple — was another example of parametric modeling paying off. The bridge’s curvature meant that each module had a slightly different baseplate angle, while verticals had to remain upright.

Using Grasshopper, the team generated railing segments parametrically and grouped them into families by angle to simplify fabrication.

“Every segment was technically unique,” said Enríquez, “but we clustered them to make it buildable.”

The same methods were reused for other components and have since been applied on several other bridge projects. What started as a necessity has become a standard approach in the firm’s workflow.

VIDEO: Tekla and Rhino Grasshopper was used to create the BIM model of the railings on the Drammen City Bridge.

A project that pushed the practice forward

The Drammen City Bridge wasn’t just a geometry challenge — it became a test case for model-based delivery and parametric workflows. For Degree of Freedom, it confirmed that these tools weren’t just experimental — they were practical, adaptable, and ready for production use.

“We’ve been working with parametric tools ever since,” said Enríquez. “This project showed us what’s possible.”

The completed bridge has been well received by the public and is now a familiar part of the cityscape.

The bridge now spans the Drammen River — a structure that appears clean and simple on the surface, but behind it is a carefully engineered and flexible digital process that made it buildable.

- END -