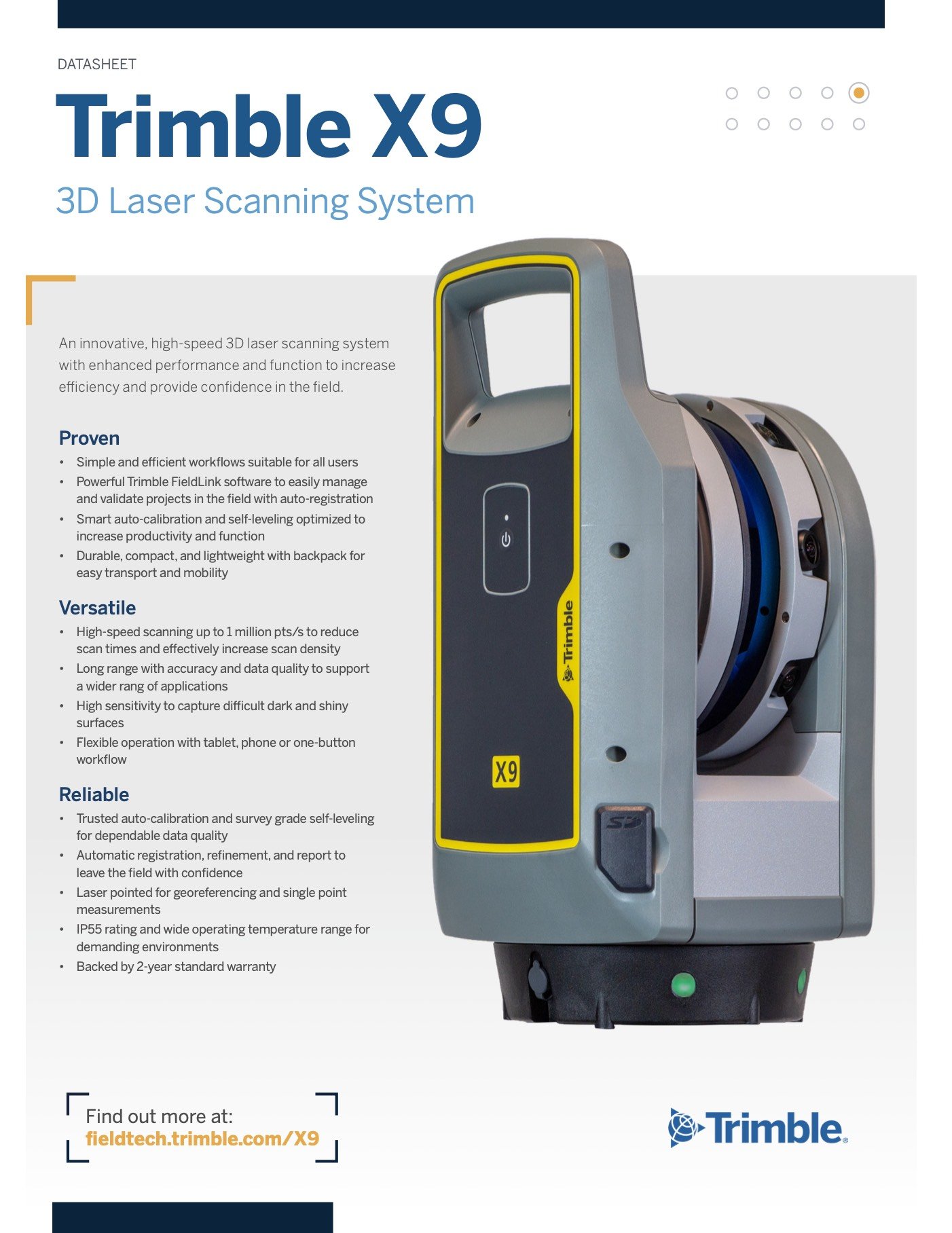

Trimble X9 3D Laser Scanner

Construction-Ready 3D Laser Scanner

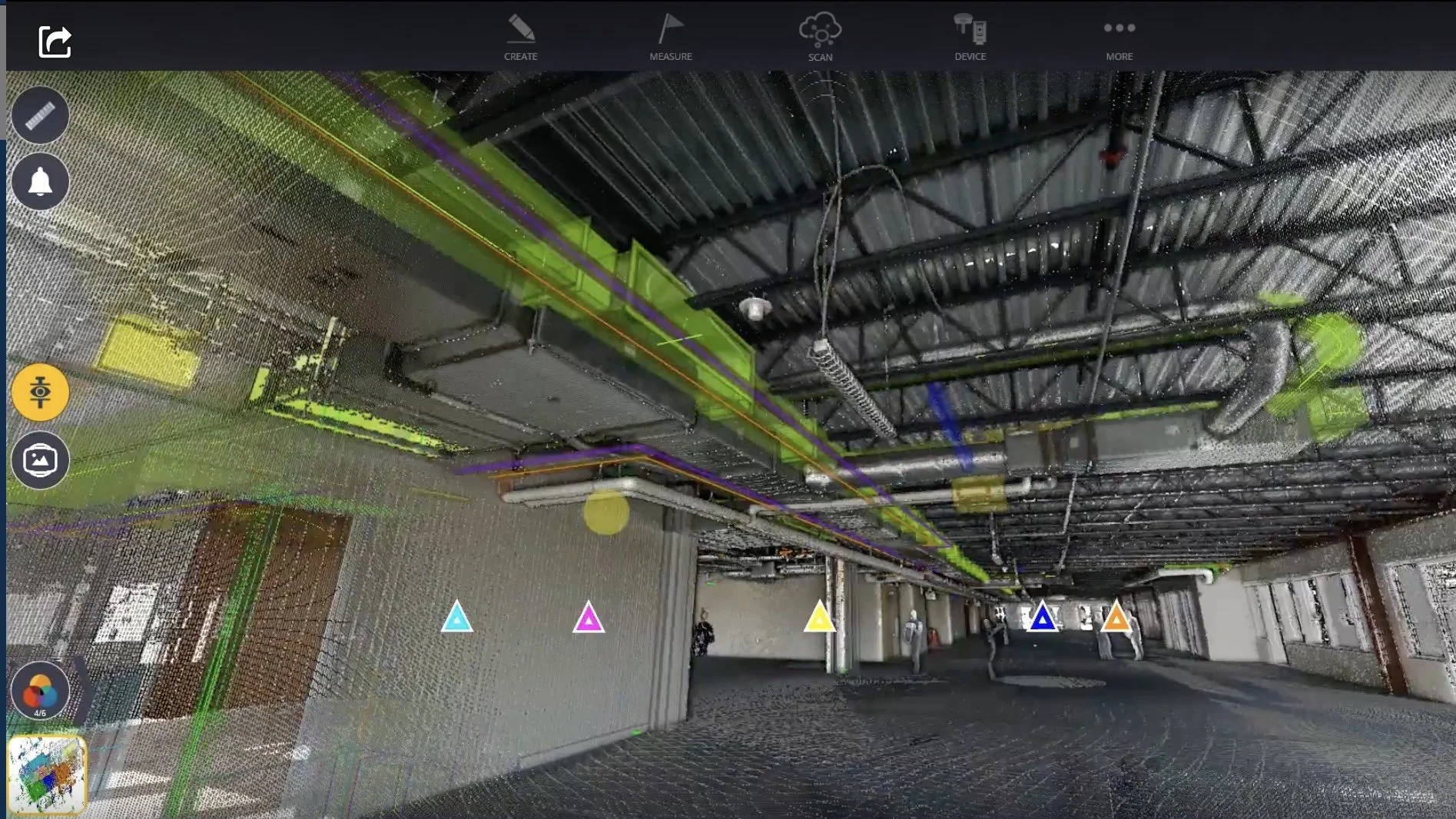

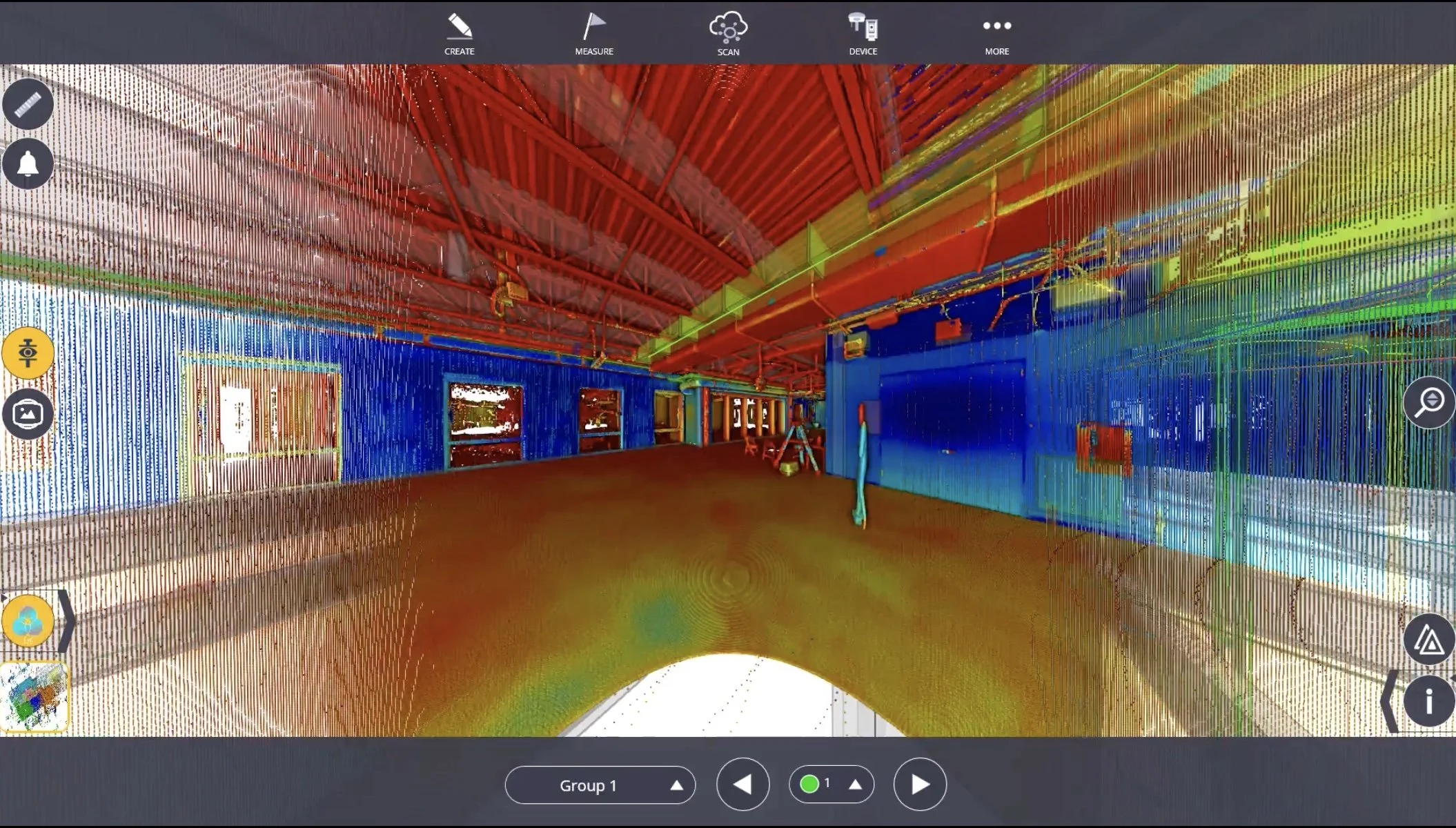

Through the versatility of Trimble FieldLink view scan data, 3D models and field layout points at the same time on a tablet controller while in the field.

Powerful Performance That is Easy to Use

Watch how the power of Trimble's X9 3D laser scanner makes everyday scanning tasks easier and more efficient.

Extend your BIM workflows and precisely capture accurate as-built conditions

Count on the X9 for guaranteed performance and accuracy so you can leave the site with total confidence in your data.

Increase Productivity

Manage your X9 with the same easy-to-use software as your layout process while also viewing scan data immediately in the field.

Reduce Downtime

With built-in self-calibration the X9 eliminates the need for annual calibration and ensures data accuracy which provides a total lower overall cost of ownership.

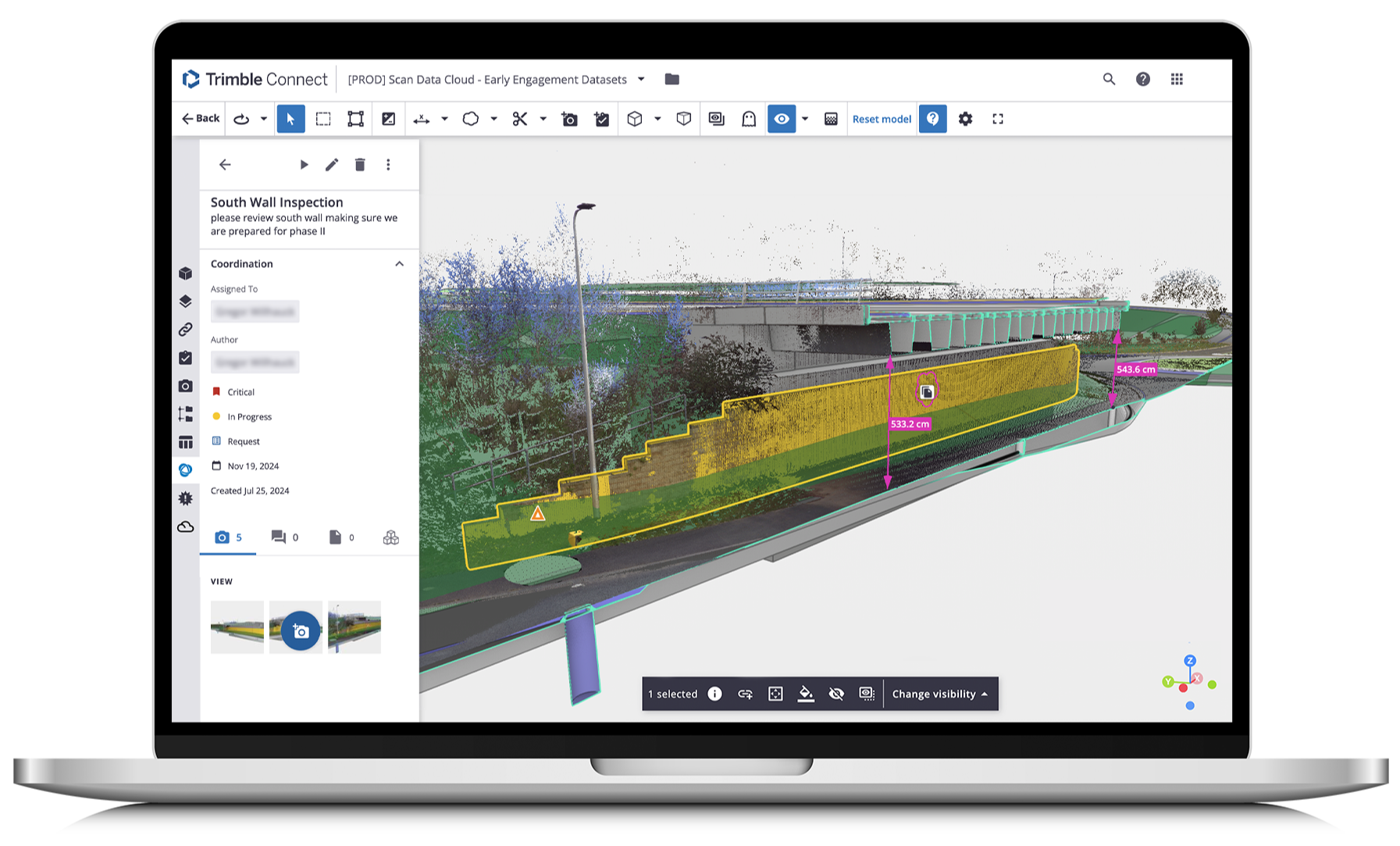

Streamline Collaboration

Export scans to Trimble Connect and increase communication between the office and field.

Collect More Detailed Data

With improved angular accuracy of 16", the X9 can capture dense point clouds which provides high-fidelity capture of the scene. This makes it ideal for for: renovations, laser layout, as-built verification, prefab, QA/QC, and more.

In-Field Registration

Increase your productivity while in the field by utilizing automatic in-field registration utilizing inside of Trimble FieldLink building construction software.

Increased Capture Range

With a longer range laser (up to 150m), the X9 can capture data from greater distances, allowing you to scan larger areas and cover more ground in less time.v

Integrated Laser Pointer

By utilizing the integrated laser pointer on the X9, users can georeference their scans to the project coordinate system. Additionally, the laser can be used to perform all your basic field layout tasks.

Fast Data Capture

With a fast capture speed (up to 1M pps) and high sensitivity laser, you can gather more usable data from complex surfaces (detailed, dark, mirrored, rounded) to ensure you get the data you need the first time.

Self-Calibration and Self-Leveling

Eliminate the need for annual calibrations and for leveling the instrument during set up, which reducing maintenance costs and downtime.

How can scanning help steel fabricators?

Steel fabricators in the Nordic were early adopters of BIM and have developed great workflows for design and fabrication over the years. Many are now looking into scanning and want to find efficient ways to consider the real world and the BIM model together for quality assurance and project planning and other benefits!

In this article we will look into some use cases for scanning focused on the steel fabricator segment!