How can scanning help steel fabricators?

VIDEO: Short introduction to scanning as part of the steel fabrication workflow. (Courtesy of Steven Ostrowski, Trimble)

Steel fabricators in the Nordic were early adopters of BIM and have developed great workflows for design and fabrication over the years. Many are now looking into scanning and want to find efficient ways to consider the real world and the BIM model together for quality assurance and project planning and other benefits!

In this article we will look into some use cases for scanning focused on the steel fabricator segment!

(This article is also available in Norwegian!)

What is laser scanning?

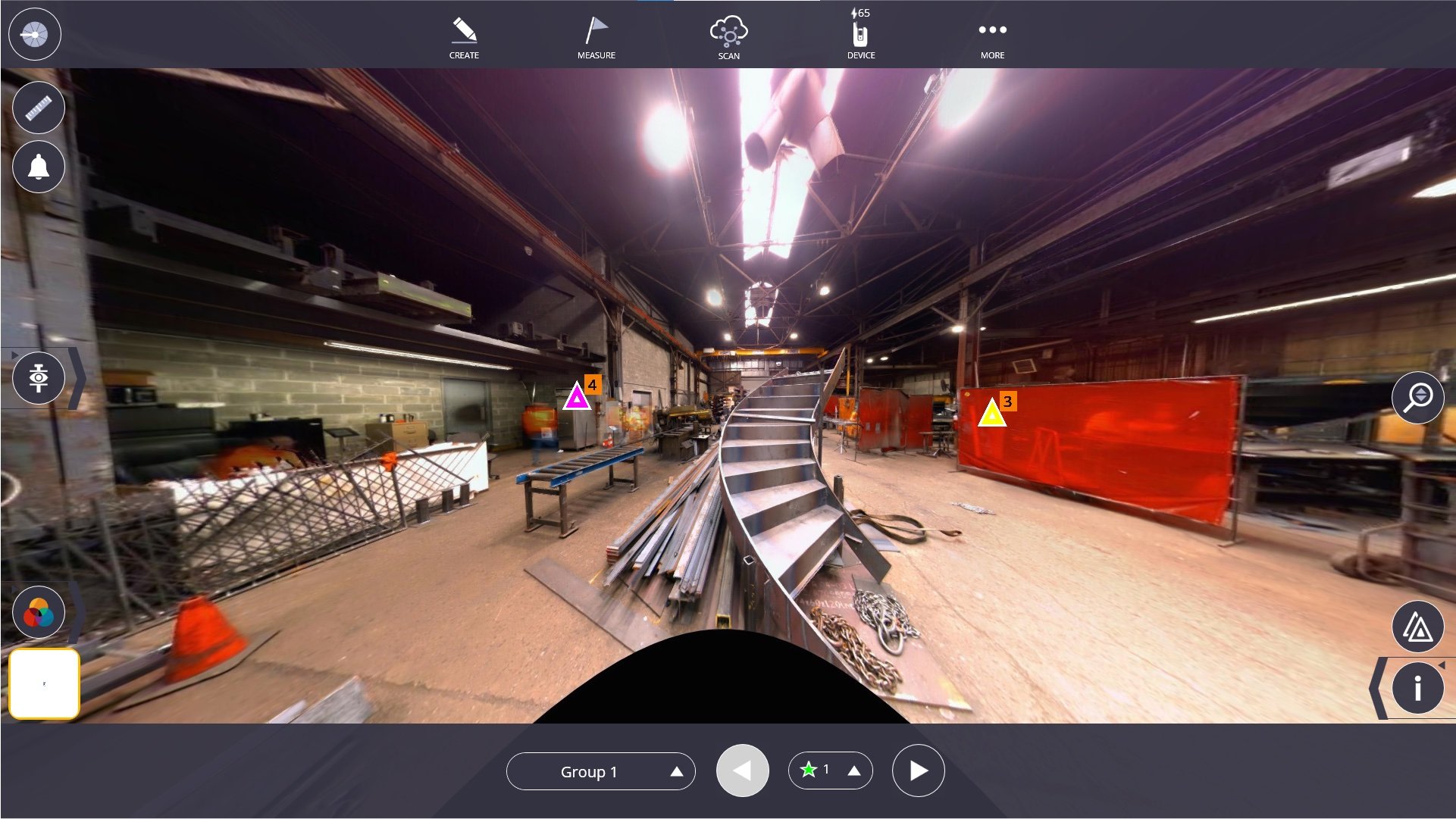

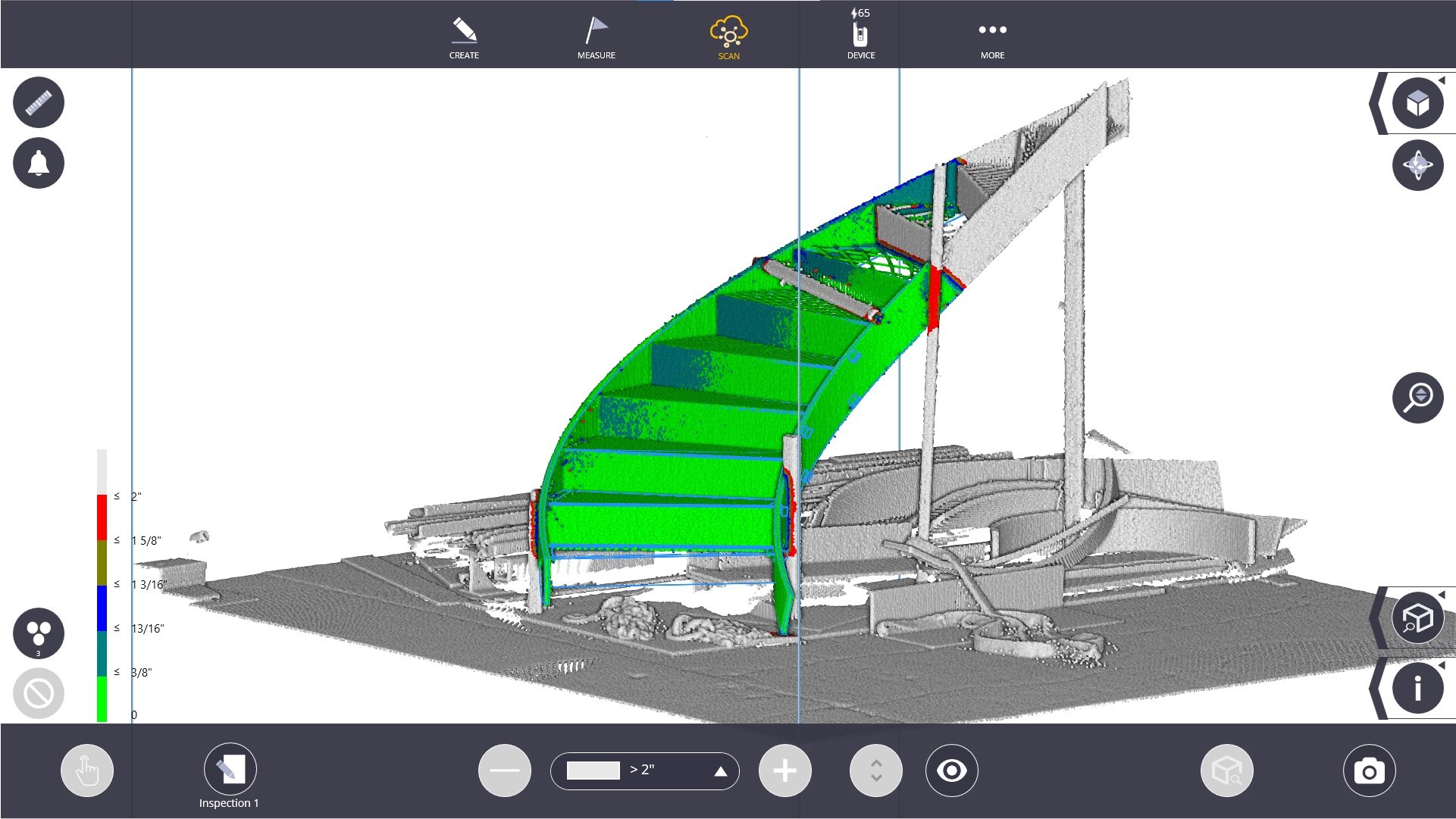

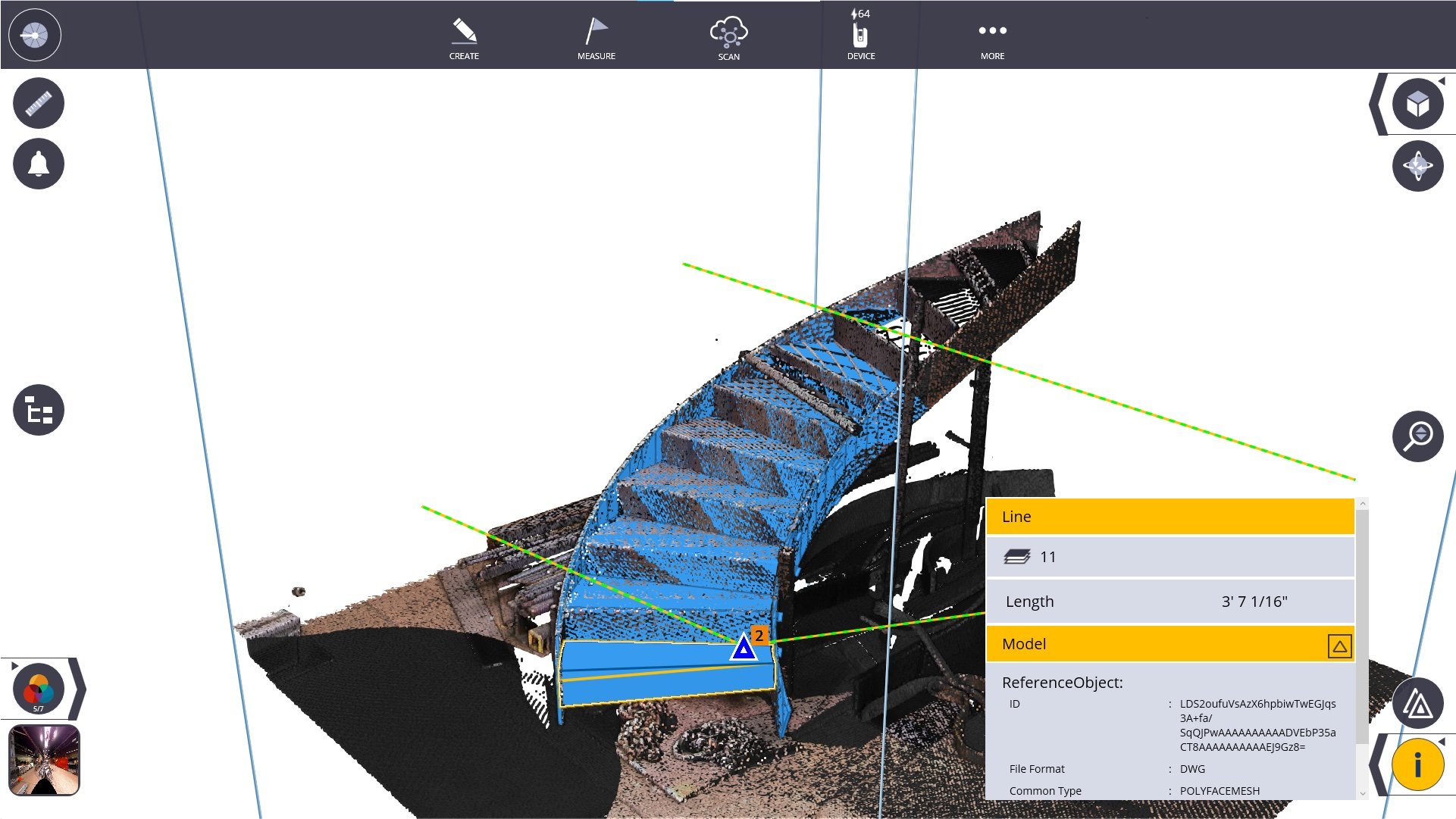

IMAGE: Trimble FieldLink software is used to operate the scanner and perform quick analysis on site.

In short, scanning is a process where a laser is pointed at a surface, measures the distance and records the position. This is done thousands or millions of times resulting in a point cloud, a digital representation of the structure, that can be used along with the BIM model.

The accuracy of the position of the points are usually within very few millimeters. The scan can be done from several locations such that one can cover all sides of a structure, or areas that are hidden by beams, walls etc. The scans can be combined to give you a full model of a structure. The density of the point cloud can be specified and there is a trade-off between time and how dense point cloud is needed.

Point clouds

The scan data is a point cloud, not a surface or solid model! To create surfaces one need to process the data in a suitable software.

However, to perform analysis or use the data, one does not necessarily need a surface model, one can use the point cloud directly in many cases.

There are many software options for working with point clouds. The scanners we offer comes with the Trimble FieldLink software which can perform many analyses on the fly! For further processing of the point cloud, we recommend Trimble RealWorks.

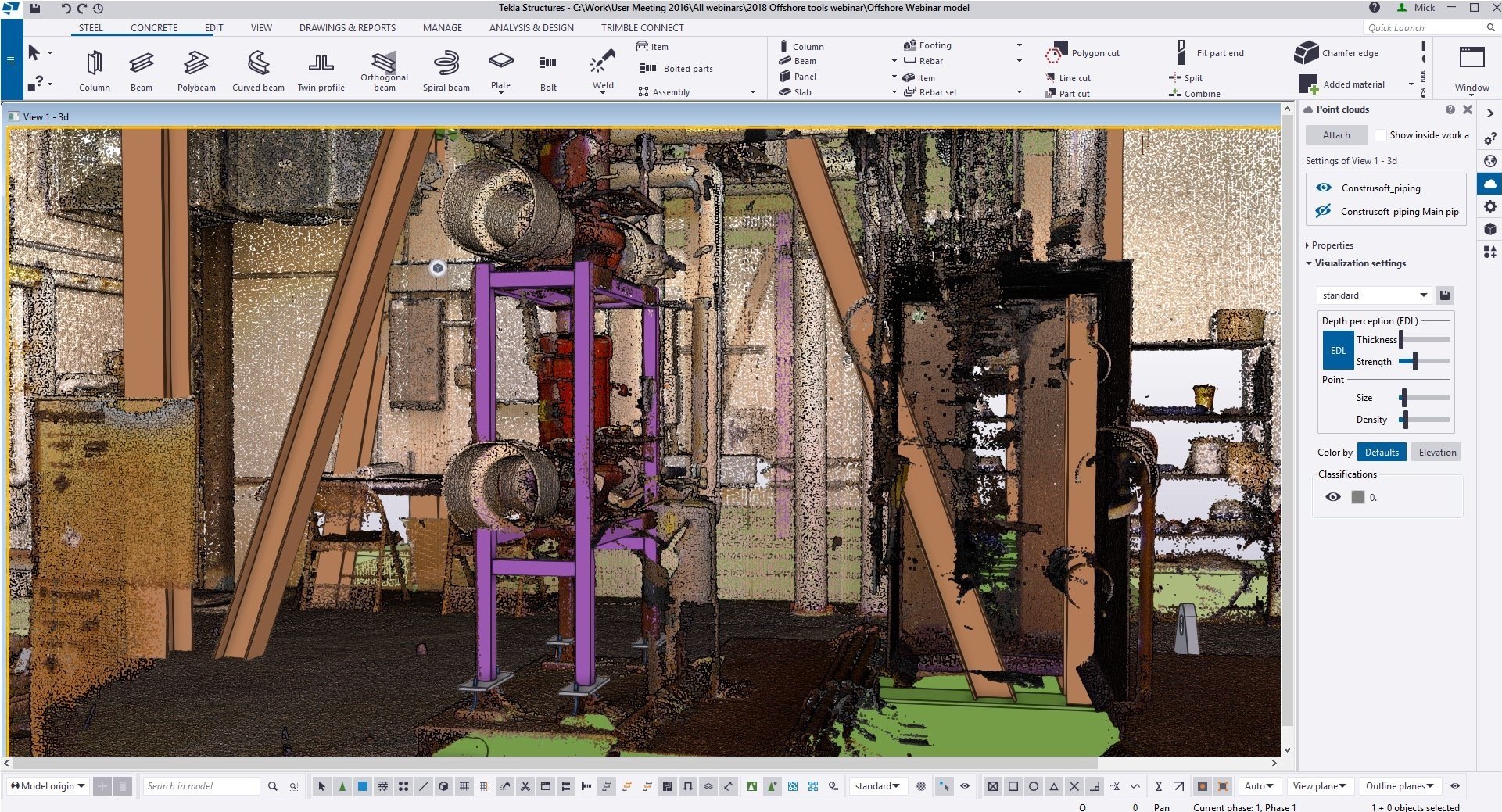

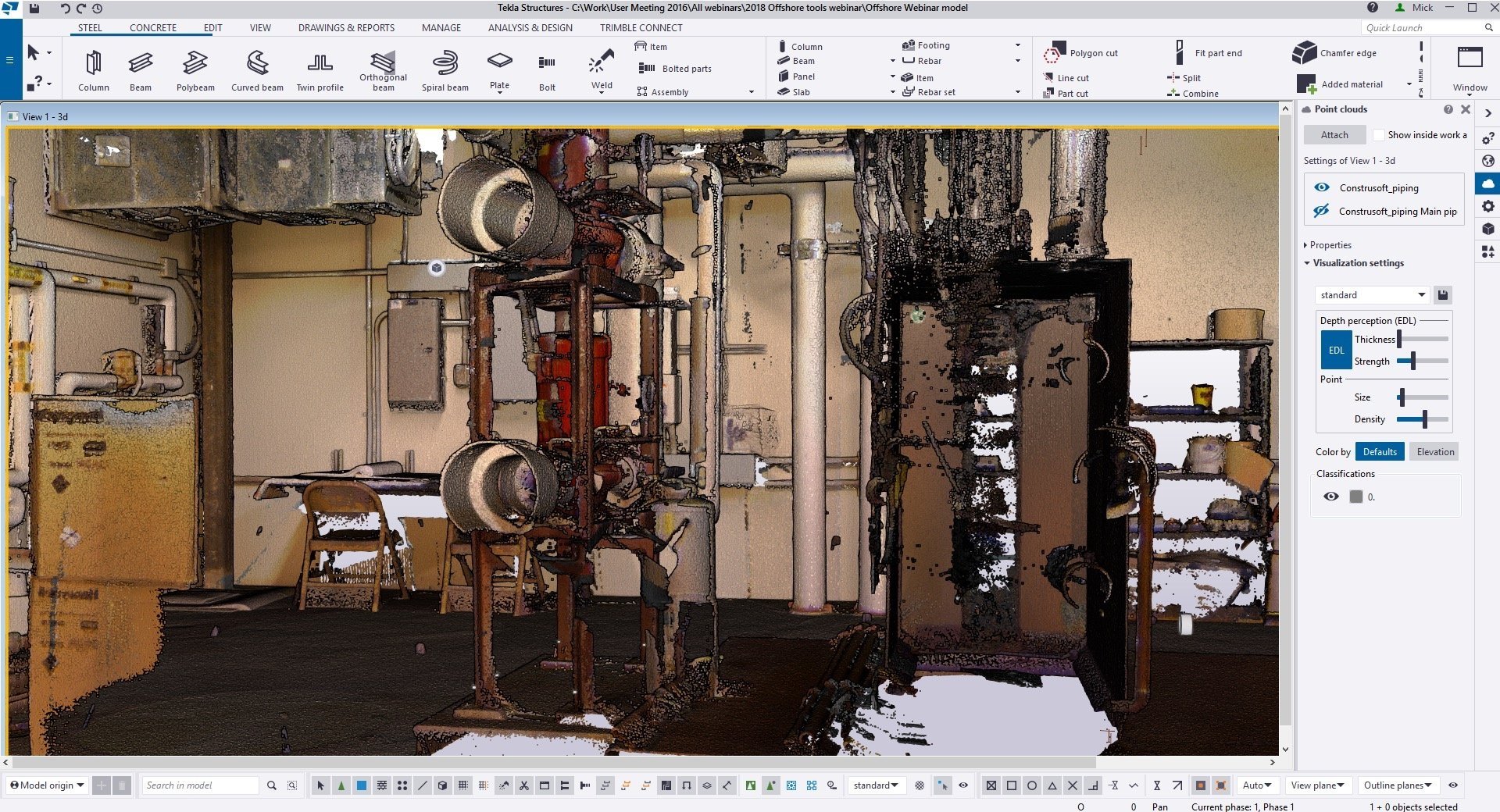

IMAGES: View the scan data and the BIM model in Tekla.

Scan data in Tekla

Many also want to import the point clouds into Tekla to work with a BIM model along with the scan data. One can import the scan data directly into Tekla, but in some cases the process will be smoother if the point cloud is cleaned up in RealWorks before it is imported to Tekla.

SHORT VIDEO: Scan data inside Tekla Structures

Scanning use cases for steel

Steel fabricators can have many benefits from using scanning: For refurbishment projects, it is very useful to have an accurate scan model to start from in design. In fabrication scanning can be used for quality control, and after installation on site, scanning can be used to verify and document correct installation.

Use case 1:

Scan existing structures and bring them into Tekla

IMAGE: Scan data inside Tekla. (Click to view large picture)

For refurbinshment or modification projects, you can scan the site before engineering starts, or even to prepare a bid - faster and more accurately!

With scanning you can capture all the measurements you need in 3D with context (360 images) and save 10s or 100s of hours in understanding true site condition - and avoid having to go back to perform additional measurements missed the first time…

Scanning can save days surveying and avoid using ladders, lifts etc., enhancing health and safety.

You can compare scan data with existing plans, understand any discrepancies before starting fabrication design. Confirm locations of concrete pads, any existing utilities or obstructions - avoid costly delays or rework at erection stage.

Export the point cloud directly to Tekla to shortcut design via Trimble Connect. Document any issues or errors accurately to aid conversations with other trades and stakeholders during project! Stand out as the digital leader in your projects, collaborate and discuss issues with better insight into the real conditions on the site!

Case Study:

Hillcrest Structural

(Courtesy of BuildingPoint UK & Ireland)

Use case 2:

Quality check in production

Scanning is a great way to do quality control in the workshop!

After welding - compare as built assembly against model.

Ensure assembly will fit when delivered to site - eliminate rework and additional cost.

Perform inspection on the shop floor so mistakes can be rectified as early as possible

FieldLink can identify elements out of tolerance with 3mm accuracy and you can generate data and reports to prove quality and compliance of work.

Export the point cloud directly to Tekla and have seamless sync via Trimble Connect.

Use case 3:

Quality check of installation

During installation

Scan during erection to track and document progress accurately - invoice quickly and confidently avoiding arguments.

Understand any small deviations or errors early on to establish impact on later installation.

Trimble X9 Laser Scanner

IMAGE: Point cloud with colors representing deviation from design. (click for larger picture)

After installation

After installation, you can perform a Post-installation scan to verify that the work has been carried out within tolerance. Then you can import installed as-built data back into BIM.

An added benefit may be to include the scan data as a deliverable for the client/project to aid coordination of following trades - helps to win work!

Summary

Companies that start using scanning as an in-house service reports these benefits:

Revenue, cost & time

✓ Dramatic reduction of on-site costs

✓ Increased productivity on site – surveys that had taken several man hours or even days were now taking a matter of minutes

✓ Option for clients to have an exact 3D model of their works and a very detailed operation and maintenance manual

Technical benefits

✓ Easy clash detection – surveyor simply runs the clash detection option in FieldLink on site or in the workshop

✓ Ability to detect errors on the point cloud and adjust the design accordingly in the office rather than discovering the error on site

✓ Reduction of risk – as built checks are carried out on site to check for discrepancies or errors in the steel frames/other subcontractor works.

People & Teams, Communication

✓ Excellent visual representation of a project for those in the office

✓ Ability to use the same point cloud to answer new questions with no return to site required

✓ Attracting talents because of use of modern technologies and digital workflows!

Let’s talk!

Fill out the form, and we will get back to you to talk about what it takes to get started with scanning as part of YOUR daily work…

Credit: Many thanks to Trimble and BuildingPoint UK & Ireland for contributing to this article!

OTHER ARTICLES