Precast Concrete

A model-based workflow with Tekla software minimizes costly surprises and waste, improves efficiency and quality, and ensures that the correct, error-free elements are delivered in the right place at the time.

“

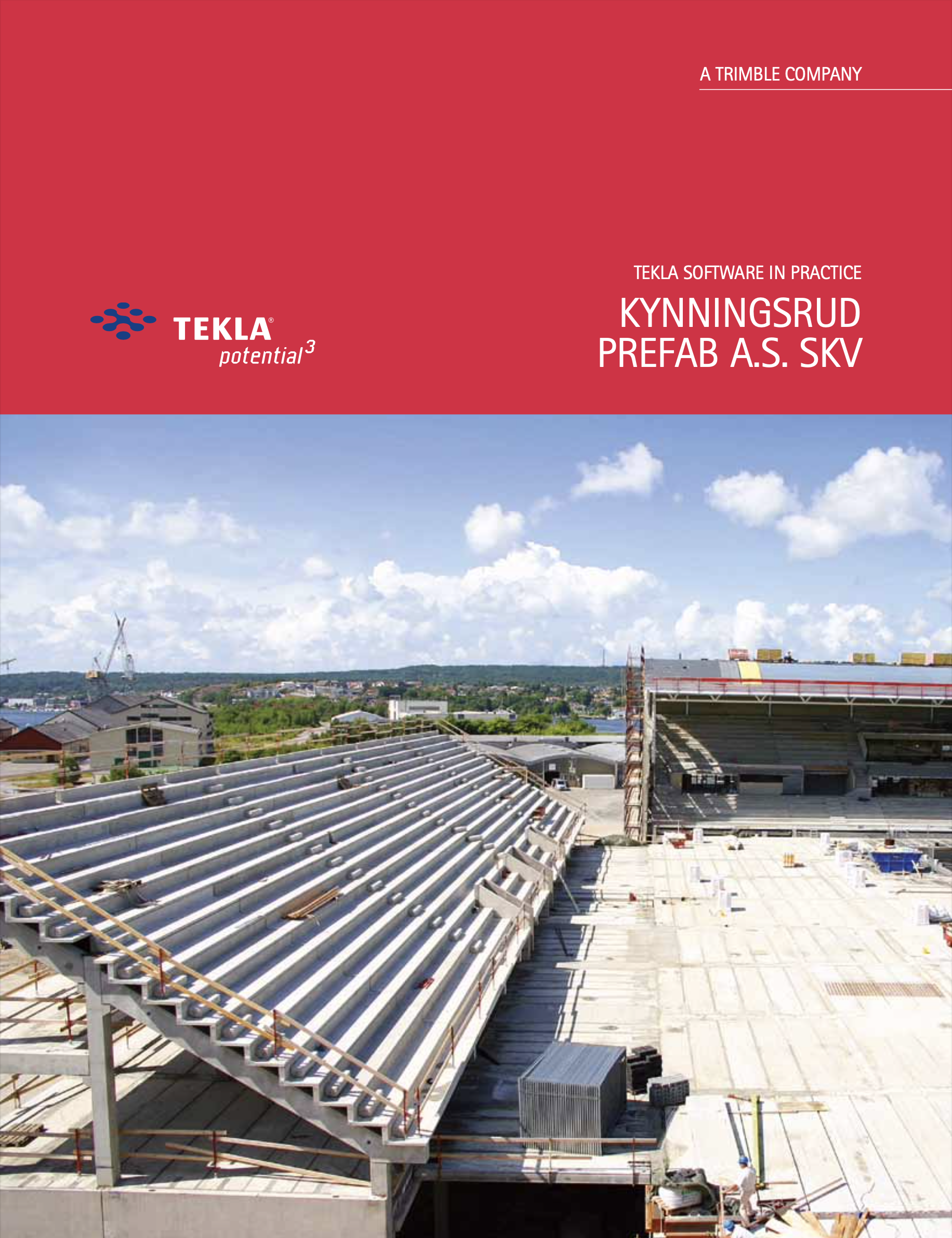

The stadium project was relatively detailed and complex. We needed to erect new elements between existing ones. The 3d model was our main reference point, enabling us total control over the entire project. Kynningsrud Prefab could not have successfully accomplished this delivery without Tekla Structures.

— Alen Zukanovic, Structural Engineer, Kynningsrud Prefab

Webinar: Accelarating Precast Concrete Manufacturing

During the last 25 years, Tekla has become the main tool in the Norwegian precast concrete sector.

Watch the recorded webinar with Thorsten Hertel and Eivind Berg to hear about how the industry is evolving and how technology like Trimble's BIM solutions, including Tekla Structures and Trimble Connect, are shaping the future of precast concrete workflows

DOWNLOAD THE E-BOOK:

How to succeed in precast detailing - every time!

Detailing is often seen as simply creating drawings for production. However, with the right tools, detailing becomes a tightly linked part of the process.

You, as a detailer, can eliminate expensive errors, while keeping your focus on the fluent drawing delivery. What’s more, at the same time, you can produce accurate information, which can benefit the entire workflow for better profitability…

Tekla for Precast Concrete

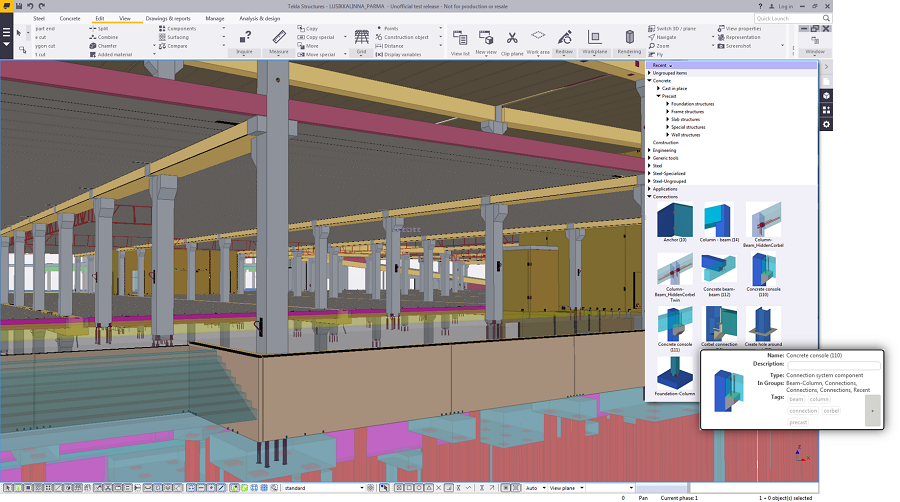

The software allows you to model all types of precast structures complete with connections, concrete embeds and even the most complex rebar. Tekla works with all materials regardless of the size or complexity of your project.

The constructible Tekla model includes all the information for generating drawings, reports and fabrication data. As project changes in the model can be automatically updated to all documents, the information stays consistent. This prevents human errors and reduces manual work.

Accurate 3D information helps everybody understand the design intent and improves collaboration between design, factory and site.

Customer Testimonials for Precast Concrete

Precast concrete detailing

BIM Software for accurate, error-free precast concrete detailing

Errors, conflicting detailing documents and inefficient information transfer lead to wasting material and resources and costly rework in the detailing department, factory and on site. When you detail with Tekla Structures you can find clashes and potential problems already at the office with your building information model, not on site.

The software allows you to model all types of precast structures complete with connections, concrete embeds and even the most complex rebar. Tekla works with all materials regardless of the size or complexity of your project.

The constructible Tekla model includes all the information for generating drawings, reports and fabrication data. As project changes in the model can be automatically updated to all documents, the information stays consistent. This prevents human errors and reduces manual work.

Accurate 3D information helps everybody understand the design intent and improves collaboration between design, factory and site.

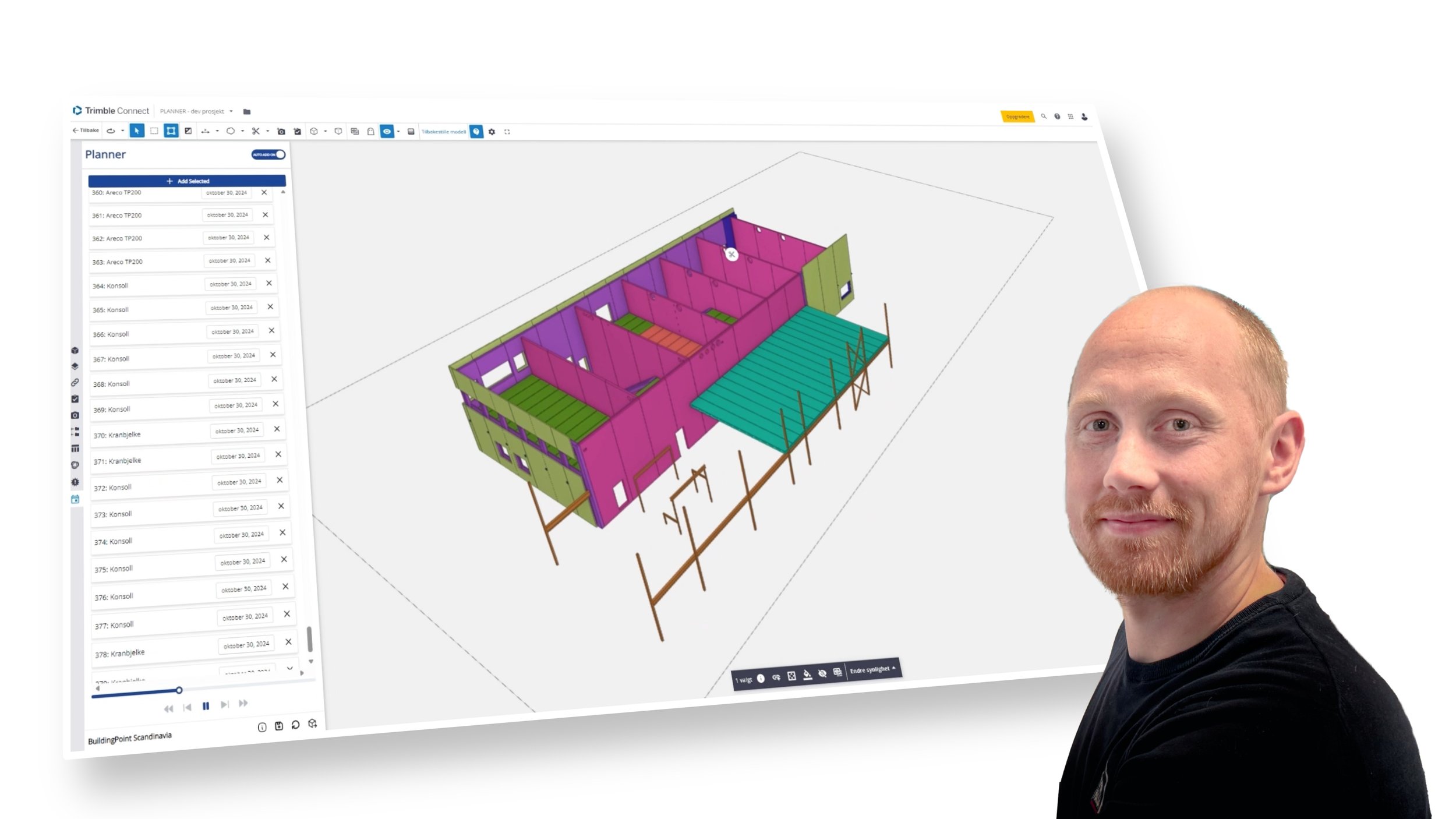

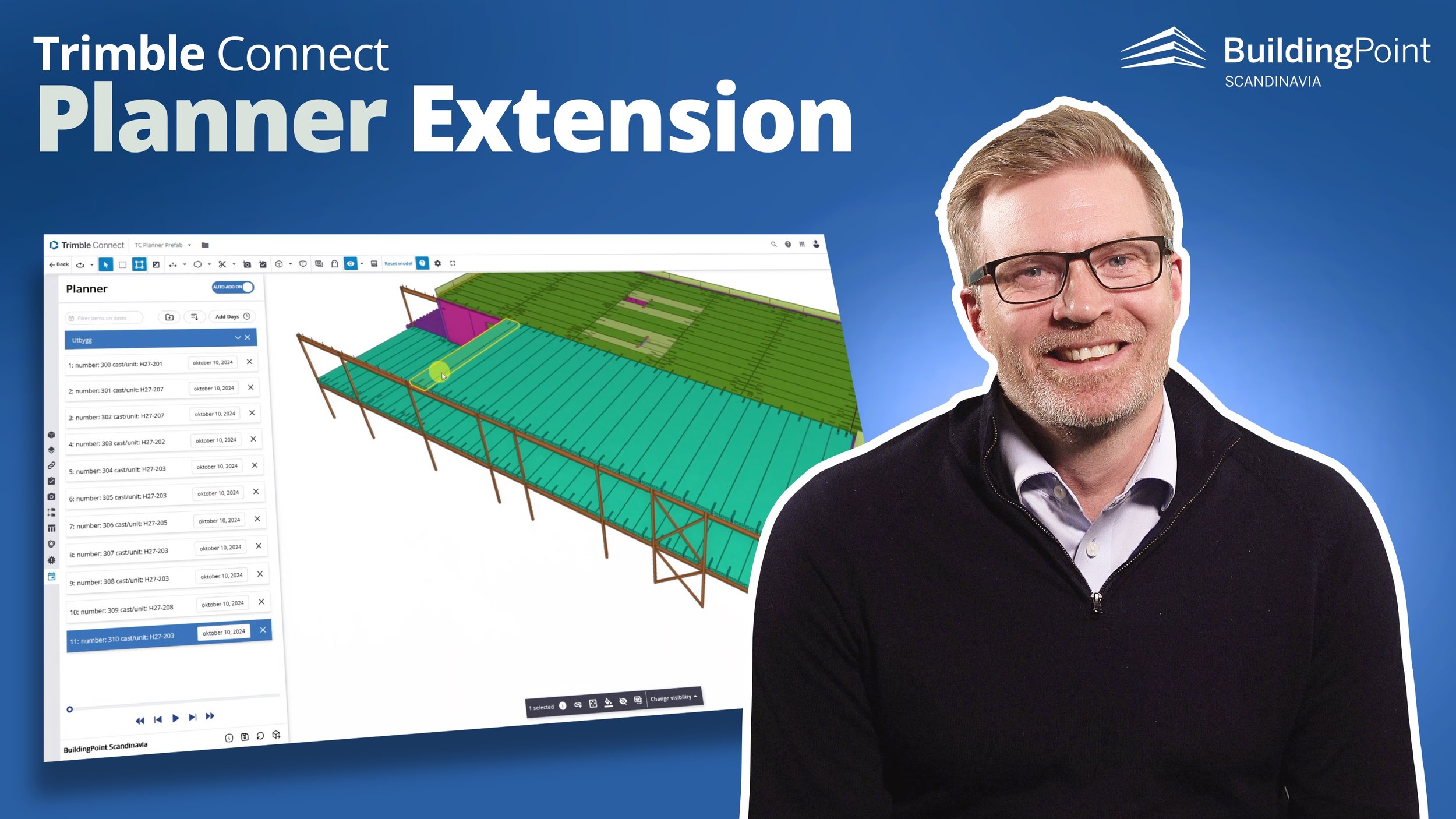

Overhalla Betongbygg improves planning with the Trimble Connect Planner Extension

Overhalla Betongbygg, a leading player in Norway's construction and concrete industry, has experienced increasing complexity and size in their projects in recent years.

To improve installation planning, they have collaborated with BuildingPoint Scandinavia to develop the Trimble Connect Planner Extension, a customized and user-friendly solution that effectively meets their needs!

Fabrication

Easy access to accurate data for planning and controlling precast fabrication

Inefficient transfer of fabrication data, incorrect or inaccurate documents and insufficient communication between project members lead to waste, unnecessary work and affect production quality. Model-based workflows increase productivity, enhance information transfer, prevent human errors and help staying in schedule.

The accurate Tekla models offer easy access to quantities, geometry and material information for planning and controlling fabrication. The software integrates with precast concrete and rebar production machinery and it offers open, readable data for production management. When the constructible Tekla model is used as the source of information, you always have the same consistent data to utilize for material reports, fabrication drawings and data files created for CAM software.

Sequence and status information in the as-built models make planning and monitoring production easier and ensure reliable delivery according the schedule. With easy-to-use mobile solutions, everybody can enjoy the visual model information. This allows fabrication personnel quickly understand the design intent and improves both the efficiency and quality of the production.

DOWNLOAD THE E-BOOK:

How to Stay Competitive in Precast Sales

In the sales phase, it’s sink or swim: you’ve got one shot to prove to a potential client that precast concrete—and your precast concept in particular—is the best choice. Here’s how, with the right tools, you can win more bids, improve profitability and optimize your entire workflow...

Precast concrete estimation and bidding

BIM Software for Successful Precast Concrete Projects

When you work on a precast concrete construction project, estimation and bidding are among the most important phases of the process. Model-based working helps you manage risk, win more bids and grow profits.

With Tekla software you can quickly create conceptual models and generate accurate quantities for estimation, visualize structural solutions that meet your manufacturing and company standards and then present the optimal solution to your client.

Precise quantity take off reduces risks when bidding and model-based working helps you ensure that project can be built efficiently in terms of time, cost and safety.

Planning and coordination of precast concrete

BIM software for reliable precast delivery and smooth erection phase

Delayed element delivery can set a site in a standstill and flawed products can create costly rework, wasting both time and resources. A BIM-based workflow and the information in Tekla models helps you ensure that the correct elements are delivered error-free to the right place at the right time.

Model-based workflows with Tekla help project planning, following up the progress and keeping all parties of the supply chain well informed at all the stages of the project. Utilizing the status information in the model is a clear and effective way to coordinate the project and ensure its progress according to the schedule.

Information rich models enable better project understanding, potential problems become easier to identify and because everybody stays informed also safety is improved. Adaption to the project changes becomes flexible when everybody has the same view of the project situation. Reporting to the client is straightforward with the 3D visualizations.

With easy-to-use mobile solutions, the model information benefits everybody regardless of location and computer skills

VIDEO PLAYLIST:

Tekla for Precast Concrete