Innovation and Enthusiasm for a Sustainable Construction Industry

VIDEO: Short introduction video with Jacob Drachmann, CN3

‘Enthusiastic’ is a description that fits the Tekla user community in Scandinavia, and one of the companies that stands out in the crowd is Danish consulting and technology company CN3 A/S. The BuildingPoint Scandinavia team stopped by CN3’s office outside Copenhagen to find out what the drivers behind their enthusiasm are and how these drivers fit in with global trends.

Innovation to support evidence-based decisions

Enthusiasm is strongly linked to enjoyment… and an engineer’s source of joy is often found in being allowed to create and innovate! Starting from the top, with founder and CEO Rolf Carlsen and CCO Jacob Drachmann, we asked both why the company emphasizes innovation to such a high degree. What is the innovative part in their contribution to the industry?

”The shift to 3D happened several years ago, but there is a varying degree of adoption… and also different understandings of what is needed, and what the value of digitalization really is,” Carlsen says.

PICTURE: Rolf Carlsen, CEO of CN3 A/S

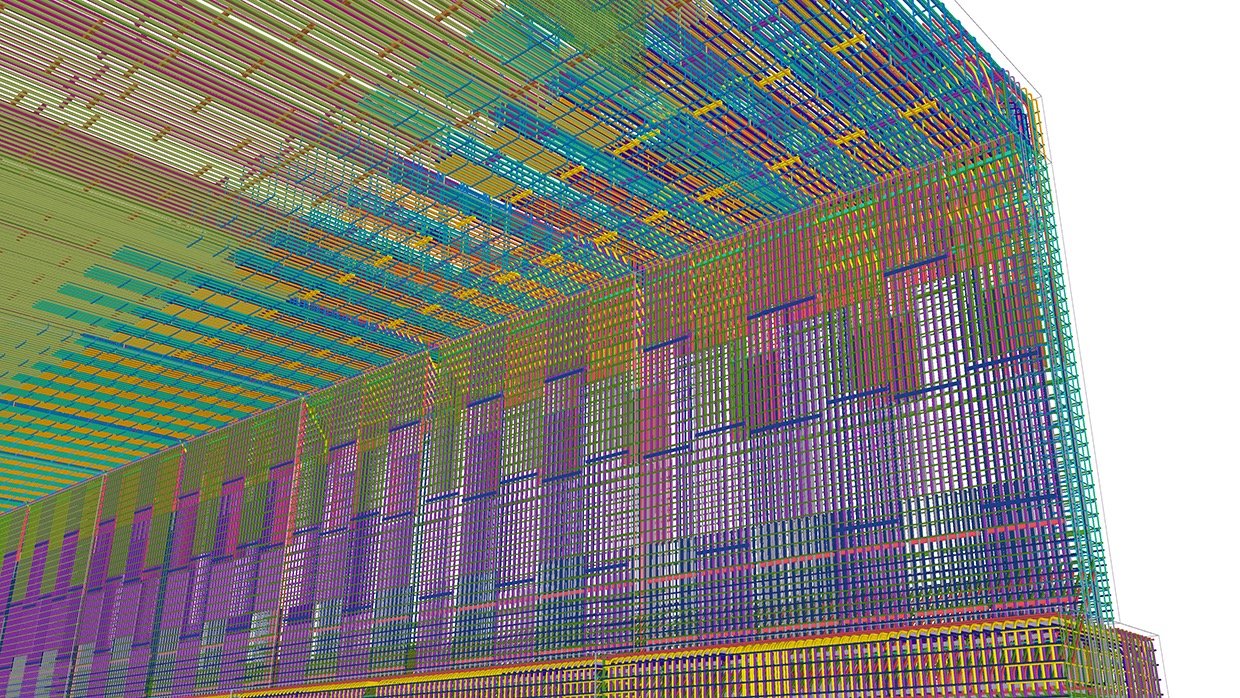

“The 3D model is the core. From there one extracts data for simulation, production, purchasing etc., including drawings, if that happens to bring value to the process! With the design software that is available today, one can quickly create design variations. By adding a bit of creativity and encouraging an innovative culture, one can create a situation where one can go from 2-3 iterations to solve a problem to 10x more iterations, and thus make better evidence-based decisions,” says Carlsen and continues:

“Tekla is a strong component in this process, but it does not stand alone. By using parametric software commercially available, or by developing software extensions ourselves to close the gaps, we can create design solutions that are highly automatic and fit for the purpose of creating brilliant design fast,” says Carlsen.

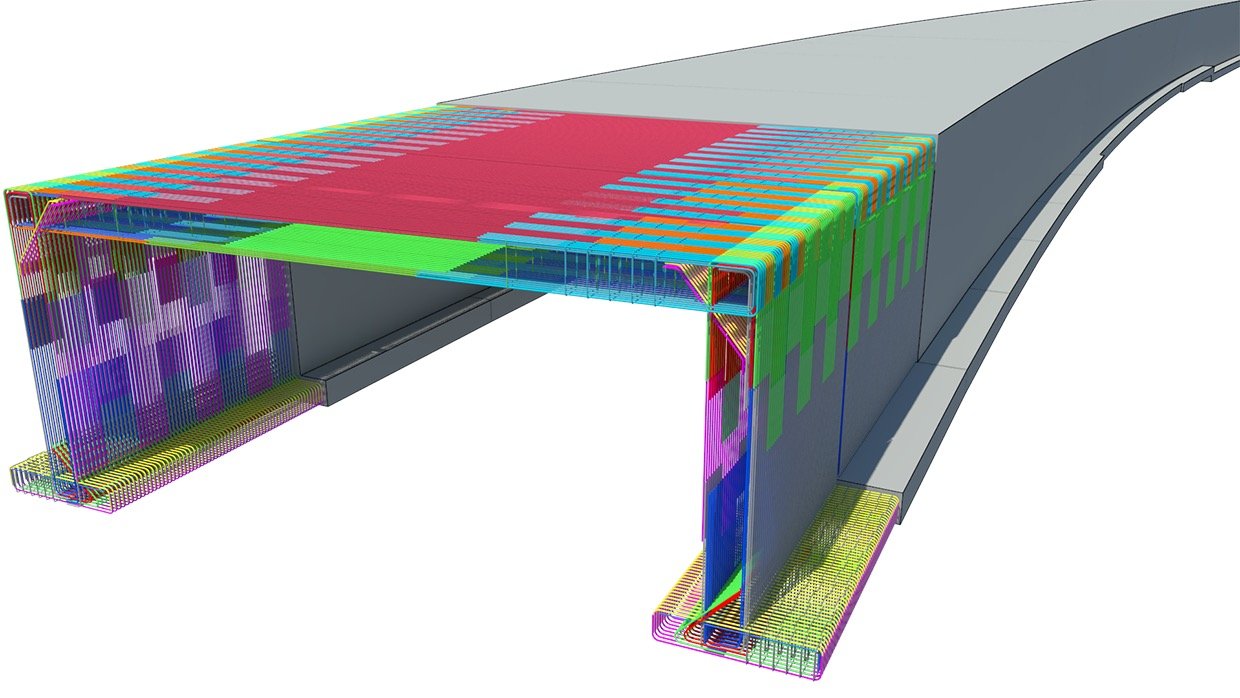

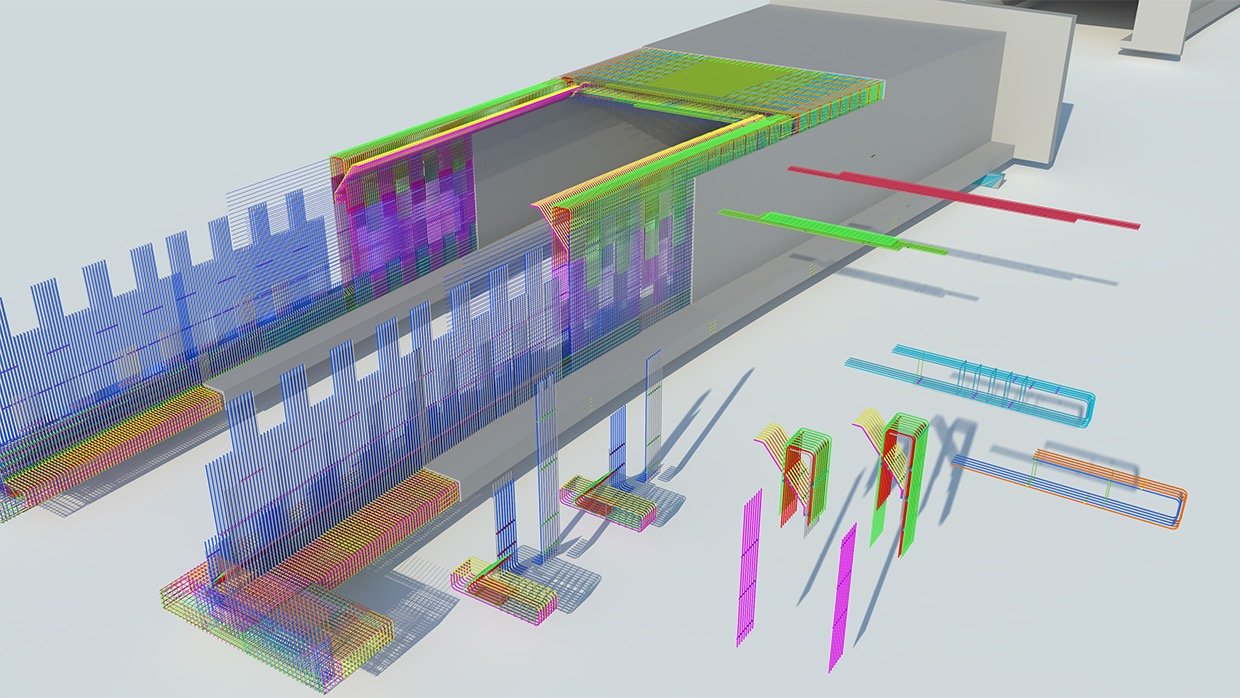

SLIDESHOW: Tekla models from Värtabanen, Stockholm. All images courtesy of CN3 A/S

Skills needed today

BuildingPoint Scandinavia asked if this puts requirements on the design team to have skills that exceed the ‘normal’ civil engineering skills.

“We have a few 'super specialists' in programming, but honestly everyone here needs to know programming, it is such an integral part of the job – and an expectation as well, to be honest,” says Carlsen.

We ask Carlsen how he goes about recruiting for this team, finding candidates that meets their needs:

“We offer education. We hold classes at DTU and host internships here at the company, and that has been a major source of talented candidates. Not everyone we train starts here at CN3, naturally, so one can consider that this knowledge sharing is a ‘contribution to the industry’ from us, for what that is worth,” Carlsen says.

“One can learn on the job as well, of course. In our ’CN3 Academy’ we take advantage of a lot of firsthand experience to train both internal and external people like VDC- starters and specialists. Training subjects include ISO19650, ICT Management or API Programming,” Carlsen adds.

Engineering for reduced impact on society

PICTURE: The UMEUS project. Picture courtesy of CN3 A/S

PICTURE: Jacob Drachmann, CN3

Having used Tekla for 10-15 years and later expanded with additional software, like Grasshopper, and even in-house developed software, CN3 has a host of successful projects behind them. We asked if CN3 could point to recent projects where digitalisation was a significant success factor.

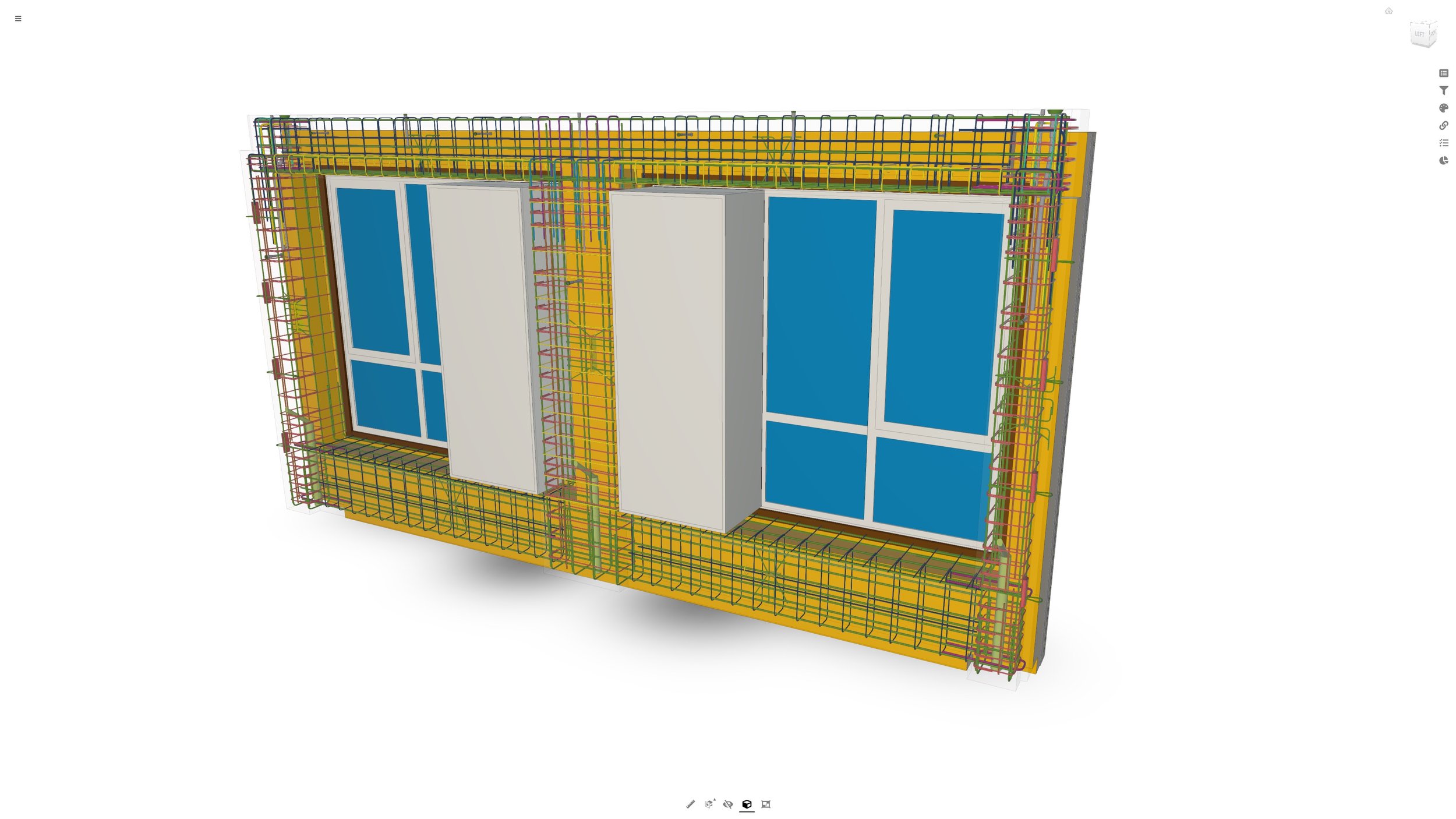

“The UMEUS project is a nice example, I think,” says Jacob Drachmann. “Building in a city often comes with a limited amount of space for the construction site. To overcome this problem, prefabrication is a great solution. CN3 delivers detailed production models and data for CNC cut and bend and assembly robots.”

“In this project, Fabricator Byldis uses prefabricated façade elements, which makes it possible to assemble without scaffolding and mount all elements efficiently. Not only does it mean that they start the interior work shortly after mounting the elements, but they also improve the work environment and increase safety on the construction site,” says Drachmann.

“Automating production, you can ensure each element is a perfect fit, and increase the production rate by as much as 40% and cut waste to 0%. Consequently, this reduces the time at the construction site, which reduces the strain on the surrounding environment,” Drachmann states.

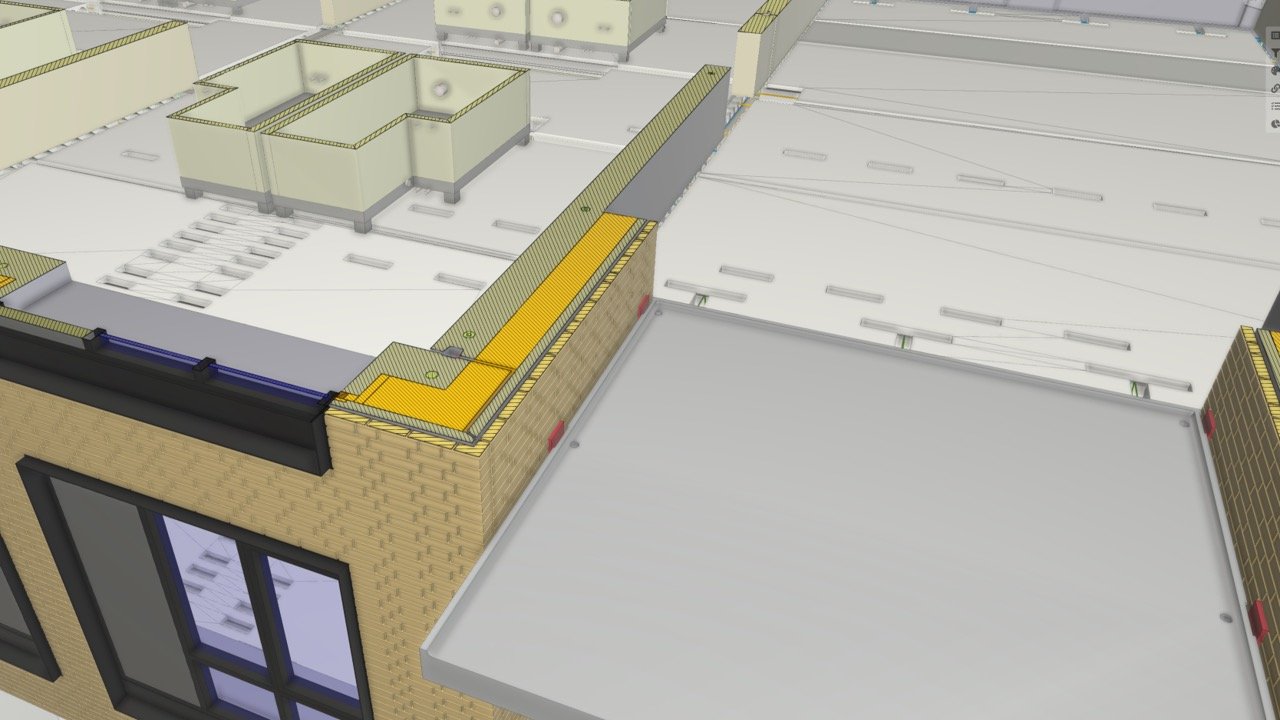

SLIDESHOW: Tekla models from the UMEUS project. All images courtesy of CN3 A/S

Sustainability as a driver

The BuildingPoint team points out that the UN’s 17 Sustainable Development Goals include several goals that address this effect directly. E.g., goal no. 9 that states that one should Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation and goal no. 11 that calls for action to Make cities and human settlements inclusive, safe, resilient, and sustainable. We ask if this is a ‘behind the scenes’ motivator, or a more up-front motivator for the team:

“I am slightly concerned about the rhetoric involved in addressing Sustainability in construction, says Carlsen. Yes, it is great that we do things faster and cheaper, but wouldn’t we try to do that regardless? Claiming it as a victory for Sustainability might become a bit hollow,” he says and goes on to explain further:

“I would like to see even more focus on the direct contribution to reduction in emissions through faster deployment of existing technologies, clever material choices, better life-cycle management and so on, things that are measurable and make the industry directly accountable! That said, there is a huge untapped potential in faster deployment of technologies and construction of green energy production that, in a smarter way, addresses large challenges like CO2 emissions,” says Carlsen.

“

I don’t think we should underestimate the effect that we – as engineers, planners and builders – can have on society.”

- Jacob Drachmann, CN3

“I don’t think we should disregard the effect that we – as engineers, planners and builders – can have on society,” says Jacob Drachmann.

“We have a tremendous impact on society if we can reduce the close-down of a city center in, say Copenhagen, from 18 months to 12 months if we do a good job. The 6 months of less disruption has an impact on local emissions, but it also allows politicians, the industry and government institutions to focus on other things – like ways to succeed in making the changes needed and not get bogged down in delays and challenges in badly executed construction and infrastructure projects. We, as engineers, can have an enormous impact in this area,” says Drachmann.

The BuildingPoint team nods and points out that, as a supplier to CN3 and the industry in general, we agree with this perspective and use it as a motivator in our team. By going through all the 17 SDG Goals and looking at the detailed targets associated with each goal, one can more clearly see where one can have influence as an engineer as well as a member of society.

“I’d still want to hold the industry directly responsible for actual emissions,” says Carlsen, smiling.

“

I’d still want to hold the industry directly responsible for actual emissions,”

- Rolf Carlsen, CN3

Taking the digital model to the real world

CN3 focuses on creative and innovative data creation partly motivated by a desire to create a foundation for evidence-based decision-making during design. But what about the construction phase of a project, we ask.

“The digital models have lived in the engineering and design offices for years, but now there are many opportunities to use the model in production on the construction site as well. Some contractors are highly motivated to explore opportunities to change how they work, while others hold back and work in more traditional ways. The shift requires motivation, and I have a good example,” says Drachmann and continues:

PICTURE: A Total Station in use.

“For the Red Bull Copenride event in Copenhagen, CN3 designed scaffolding for the tracks needed during the event. When the contractor looked at the schedule, it was clear that there was no room for making mistakes during assembly. To ensure correct assembly it was key to know that all the joints are in the correct place, and this is usually checked and controlled by a surveyor. However, the surveyor is not at the site all the time, and there was a desire to find efficient ways to build right AND do a more stringent quality control in parallel with building,” explains Drachmann.

“A Total Station is basically a robot that relates itself to control points set out by the surveyors, and when it knows where it is in the world it can use the BIM model to point the laser at positions in the structure that is being built. This way one can keep speed and reduce, or even eliminate errors while building! The extra effort is very low, the work related to measurements may be lower than tape measure-based methods. One still must do formal quality control with a surveyor, but since the build is correct, no time is lost,” says Drachmann.

Vision for the future

If you put your company’s strengths together with the opportunities within digitalization, where will you go from here? we ask.

“Our vision is to keep building value into the digital model. That can happen by adding more data, but just as important is making the data more accessible in a “Digital Twin”-like management system that creates an ability to make evidence-based decisions. We will do this through use of available technology, and then close the gap by making software solutions on top of that,” says Drachmann.

Rounding off, we ask Carlsen and Drachmann what motivates them personally. Drachmann takes the lead and says:

“To keep motivated, you must sustain your enthusiasm for your job over time. By connecting construction, cool technology, and peoples’ innovative imaginations, it becomes more fun to go to work,” says Drachmann, thus ending our discussion with everyone in agreement!

-END-

Sustainability on the agenda!

BuildingPoint Scandinavia is committed to supporting the UN’s Sustainable Development Goals to the best of our ability.

FACTS

OTHER STORIES

RELATED

BuildingPoint and Sustainability

Tekla Structures BIM Software