Spot Increasing Safety in Arctic Mining

As a contractor in mining and tunneling, maintaining safe operations is the no. 1 priority for LNS. However, increasing safety requirements puts business pressure on LNS, but it can also be an opportunity to innovate.

Dogs were an essential part of Roald Amundsen’s team during his famous polar expeditions, and they proved to be essential for success when they entered uncharted and difficult territories. With the emergence of robotic technology, dogs may once again prove to be essential to map the terrain.

PICTURE: Robot dog Spot and Dirk Niemann from LNS A/S.

Underground and Arctic Construction

Tunneling, mining and other underground construction activities involve handling and minimizing risk. As a family owned company originating in the north of Norway, contractor Leonhard Nilsen og Sønner (LNS) has always put HSE (Health, Safety and Environment) in the front seat.

LNS has always viewed increasing requirements from clients as an opportunity to engage with emerging technologies. This practice of continuous innovation has allowed LNS to become increasingly safer and more efficient, while also growing as a company. However, incidents do still happen in the construction industry, and LNS is determined to continue to aim for zero harm or injury.

Everyone’s favorite robot dog, Spot, caught LNS’ eye, and they approached BuildingPoint Scandinavia to investigate how this promising technology could fit into their operations and organization.

3D Laser Scanning

Scanning has been an available technology for many years and the business value of scan data is being realized by more and more organizations. Scan data represents an opportunity for a construction team to make decisions based on empirical evidence. With self-calibrating scanners, like the Trimble X7, it is easier than ever to measure the active jobsite conditions and collaborate in a meaningful way.

The scan data is processed in software, like Trimble CloudEngine, and the company can make analyses that let the team make decisions on how to proceed in production. LNS AS has used scanning and other means of digital data gathering for a long time. Today, they rely on scan data to make fact-based decisions in all mining and tunnelling projects.

In mining operations, the company uses scanning of mountain halls and tunnels to identify potential risks in terms of HSE, and to compare the scanned geometry to the theoretical geometry to see if requirements defined in the contracts are met.

However, it is an unacceptable risk for the operator to move into these hazardous work areas, thus, the scan includes “shadows”, (i.e. unscanned areas). This reduces the value of the scan since the data may be incomplete and miss features in the geometry that should be addressed.

“

There is a strong tendency for early adopters who break new ground to have a more challenging journey… but that’s the burden of being the lead dog!

Increasing Scanning Requirements in Mining and Tunnelling

LNS’ Head of Geomatics, Dirk Niemann, is no stranger to scanning as part of daily operations. However, in his view, the process is far from ideal, especially because project decision makers cannot get the data they need in a timely and consistent manner. When asked about the current process he explains:

“Today we do not have a process that resolves how to create a fully defined rock model without scanning shadows, unfortunately, since we often must scan from a distance. It is simply not safe to go into all the areas where we need scan data. What we want to do is process the scan data against the theoretical rock model and then work to remove rock from some areas, the underbreaks, to meet the required geometric profile. I also expect that a high-resolution digital rock model, or a digital twin, will be required as documentation for geological checks afterwards in the future, adding to the need to improve the process,“ says Niemann.

PICTURE: Spot and Dirk Niemann at LNS.

Niemann explains that mining operations and other underground construction operations are similarly challenged when it comes to safety and scanning. Generally, the requirements are lower with respect to tolerances and documentation in mining compared to e.g., road tunneling.

“In tunnel projects, we have the same challenges in creating a fully defined rock model without scan shadows. As a supporting foundation for decision making, the scan data can be used to perform a geological check, enabling us to make decisions for how many rocks bolts, reinforcement bars and how much sprayed concrete is necessary to make the area safe. In road tunneling projects, however, we already have client demands for high-resolution “digital twins” of the tunnel for geological check afterwards,” explains Niemann. He adds that this documentation requirement is also a strong driver to improve the current processes.

Autonomous Robots with a Scanner Payload

The term ‘robot’ can be defined in many ways. Although, one could consider a machine that carries out tasks in a sequential and preprogrammed manner a robot, a robot is more accurately defined as a machine that can adjust its behavior based on its own observations without human interaction. This does not necessarily imply intelligence, but it does require autonomy.

Spot, the robot dog from Boston Dynamics, impressed the world when it was first demonstrated back in 2016. As a supplier of this technology, BuildingPoint Scandinavia has met with many prospective customers, and the most common reaction is a smile :) ! Spot is simply charming, and he/it impresses everyone with his/its fluid motion when it moves around a room.

However, it is only when Spot is put to work in more difficult environments that people realize it is not just hype. Spot demonstrates his/its industry readiness by nimbly moving around obstacles and confidently climbing steep slopes.

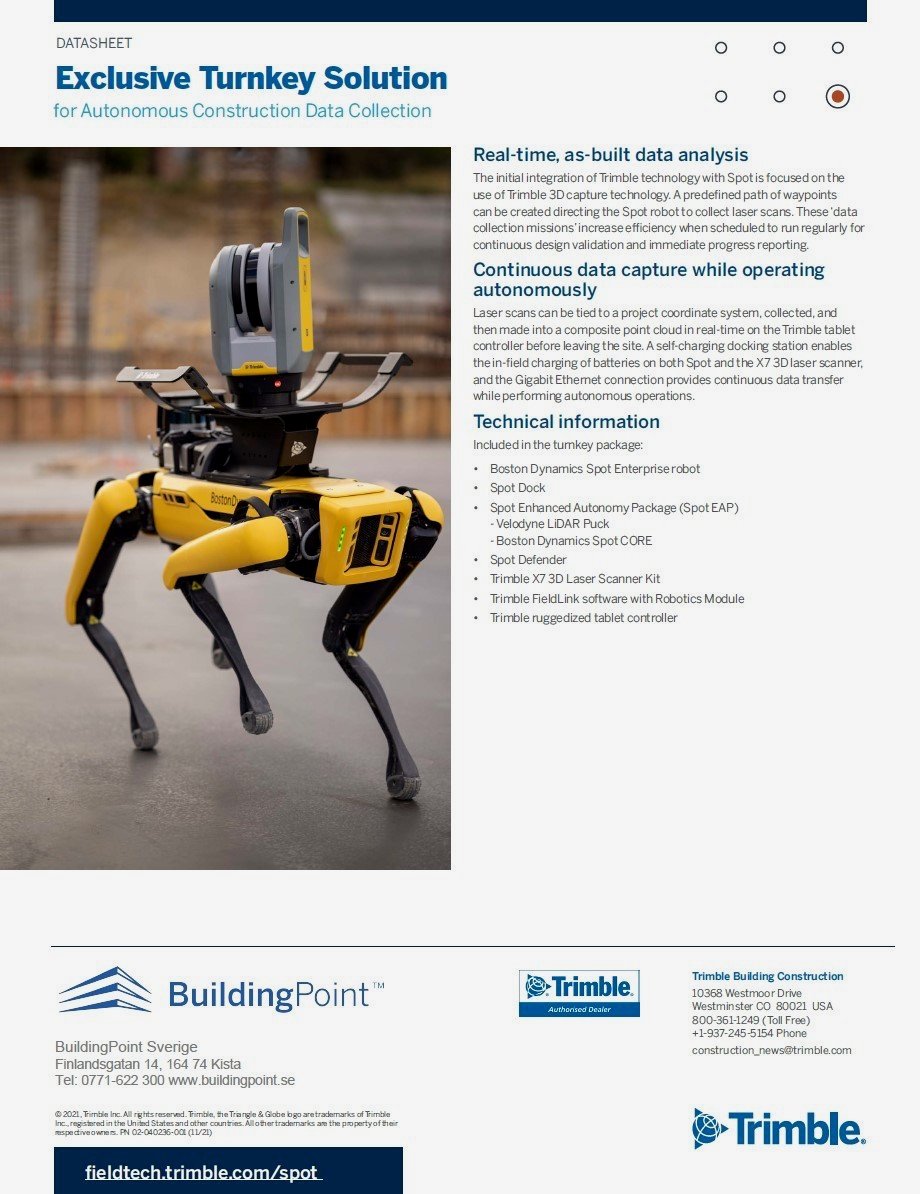

On its own, Spot is clearly ‘just in the way’, as one person put it. However, when fitted with a payload, like the Trimble X7 Scanner, Spot can do some valuable work – and that is the configuration in which BuildingPoint Scandinavia delivers Spot.

Getting Return on Investment Through Robotics

“This pilot project that Spot is part of, which is also funded by Skattefunn and the Norwegian Research Counsil, focuses on how we can generate more efficient data collection. The project will also aim to demonstrate how we can plan Spot’s route and scanning positions and generate 3D capture without the operator’s presence. This is made possible through remote operation,“ says Niemann, emphasizing that this is a goal for the last stages of the project following initial success with the operator present on the site.

“That allows for one expert to support several projects across the world with no travelling, Niemann explains enthusiastically,” perhaps thinking back on his own travelling in the past. Then he adds, “this would significantly increase LNS’ ability to use scanning in remote arctic locations by reducing the requirements to use an operator.”

“An overall ambition with Spot is to help LNS AS personnel virtually access areas considered unsafe due to safety regulations, non-breathable air, or other conditions. We know that using scan data and Spot will enable us to get better and more complete data more quickly, more reliably and more consistently where it was previously unsafe,” Niemann states.

“

An overall ambition with Spot is to help LNS AS personnel virtually access areas considered unsafe due to safety regulations, non-breathable air, or other conditions.

We know that using scan data and Spot will enable us to get better and more complete data more quickly, more reliably and more consistently where it was previously unsafe,”

- Dirk Niemann, LNS

Technology, People and Processes

Being the very first contractor in Mining to acquire Spot, and among the very first in the Nordics, LNS AS has a clear plan for how to ensure that Spot can work in conjunction with people and great processes to generate business value.

The introduction of new technologies can sometimes be perceived as a distraction, or even a threat. Niemann says he takes this seriously and explains:

“The competence that our people have is crucial to our success and any technology that we introduce must eventually, and preferably from the start, add value to people’s work and feel like an increased capability and capacity by everyone. If technology feels like an extra burden, we fail, but our people are creative and adaptive and I’m confident we will break new ground and come out of this project with great achievements,” says Niemann.

The Spot Pilot Project

Deploying new technology in a live operation requires good planning. According to Niemann, the LNS organization is used to innovation but is also focused on getting the job done without distractions. Key success factors include onboarding and training of employees, sharing information, a good definition of success criteria and a subsequent evaluation process to find improvement areas.

PICTURE: Spot and Dirk Niemann at LNS.

“We do expect challenges and problems, of course! We will deploy this technology expecting that Spot has been thoroughly tested by Boston Dynamics and that the X7 Scanner from Trimble has proven to be robust, but as all engineers know – s#%t happens! We will need to be adaptable and creative along the way. We expect the BuildingPoint Scandinavia team to follow up as an integral part of the project team, and I am fully confident that we will create value for the company this way,” says Nieman firmly.

“There is a strong tendency for early adopters who break new ground to have a more challenging journey… but that’s the burden of being the lead dog,” Niemann says with a smile!

FACTS

About LNS

LNS is a construction contractor, mining contractor as well as mine owner and operator.

They combine the best from both the construction industry and the mining industry in their projects. To ensure efficient and profitable operations, they actively utilize the latest technology and develop smart solutions and processes.

About the Spot project

The Spot project is part of a Skattefunn project called ‘Autonomous high precision mapping of mountain surfaces’.

Project targets:

To develop a methodology for safe and cost-effective mapping of rock surfaces in tunnel and mining projects. The methodology should provide a point cloud representation of the mountain surface with an accuracy of +/- 5 mm without shadows.

The project outcome should provide increased quality and lower costs for mapping mountain surfaces and at the same time improve the company's work processes, primarily regarding HSE.

MORE STORIES

Trimble Spot DATASHEET

Trimble X7 Scanner

The Trimble X7 Scanner is available as a stand-alone units as well…

MORE ARTICLES ABOUT SPOT