Spot makes Tunnel Scanning safer and more efficient for Veidekke

VIDEO: Interview with Veidekke about how Spot may help make tunnel scanning safer and more efficient

Tunneling could be considered a national sport in Norway along with other sports also inspired by the mountains and the fjords. Norway’s tunneling tradition goes back as early as 1879, ref.

However, technology has come a long way since the 19th century, and robot dog Spot is one of the most advanced and anticipated technologies to become available to improve how we do things.

Veidekke

Norwegian contractor Veidekke was established in 1936 and is currently in the top 5 list of Nordic Contractors with respect to turnover, making significant contributions to infrastructure.

Veidekke base their operations on values like “breaking boundaries” and “enthusiasm” and a strategy that encourages innovation to create value for their customers and society. It was obvious to BuildingPoint that Veidekke should be the very first in Scandinavia to put our newest product, Spot, to practical use. This collaboration will help find out if there is a potential for improved processes and increased safety related to tunneling.

Spot – the Autonomous Scanning Solution

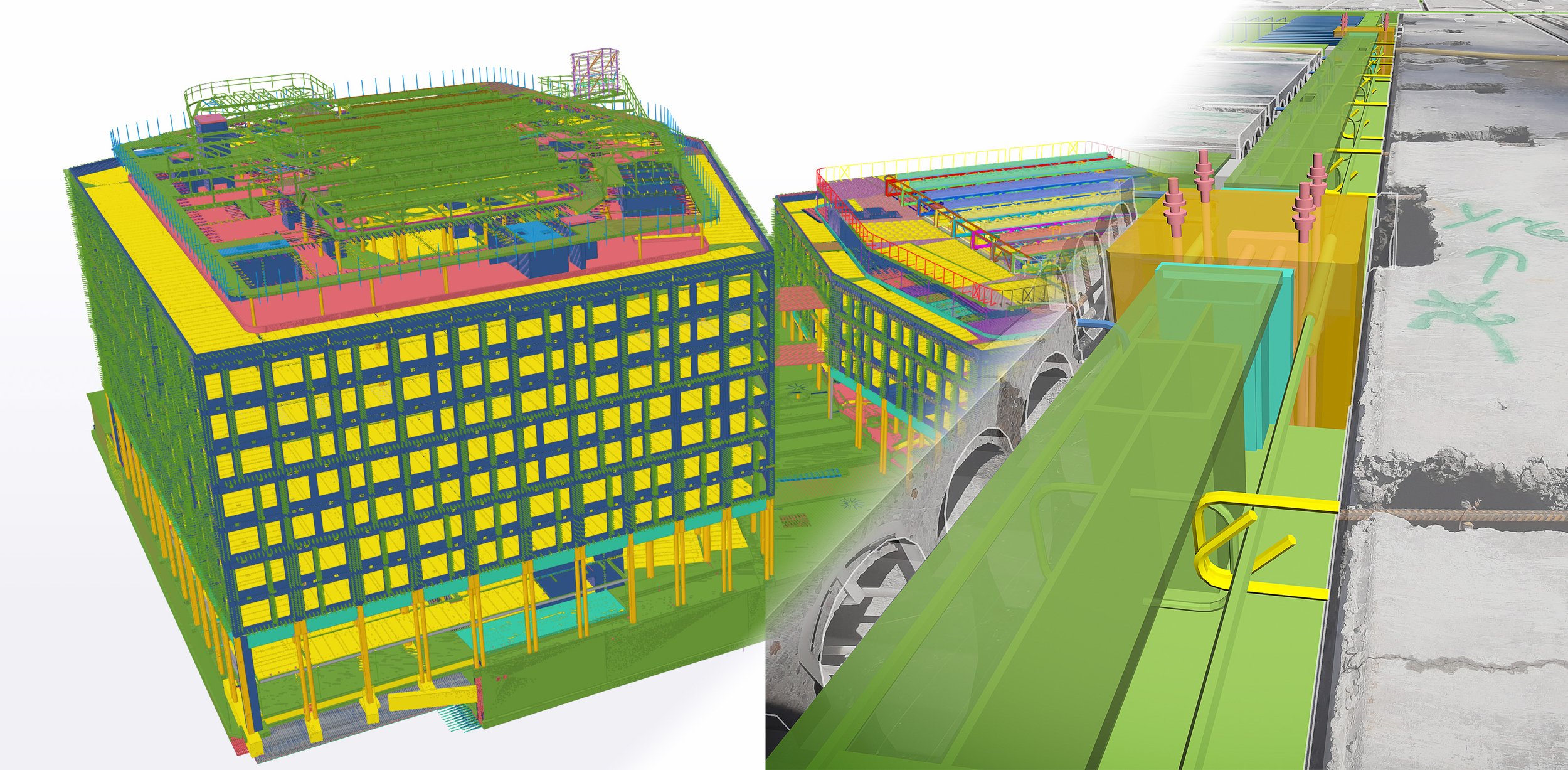

The base mobile robot chassis, Spot, was created by Boston Dynamics. For operations in the construction industry they partnered with Trimble to fit Spot with payloads like scanners and total stations. With the Trimble X7 Scanner, Spot is effectively an “Autonomous Scanner Solution”.

Tunnel Scanning

According to Øyvind Svaland in Veidekke, scanning is already widely adopted as a method for data and knowledge gathering. The scanning is done by operators on the ground, or by drones. The scan data allows for quicker and better decision making in many cases.

“Today we use scanning a lot! The use of scanning is actually increasing and we see a great value from it. At the same time, we see many opportunities to improve the process to be sure that we get scan data continuously,” says Svaland. Continuing on, he explains that all scanning inside tunnels are made by an operator today, meaning that a skilled person has to be on-site to carry out the scan, which sometimes limits the availability of the scan data. Since they have adopted scan data as a basis for decision making and communication, the absence of the data may be negative, and that is a potential for improvement.

Having an on-site scanner that could be operated remotely would limit the need for having the expert on-site, which would be possible with Spot sitting on his charging station, ready for ad-hoc missions. Additionally Spot could potentially carry out scanning based on preprogrammed missions, for example at night between when operations are on hold.

“

There are many benefits of Spot, particularly related to safety for people, autonomous repetition of tasks and increased flexibility in our operations, ensuring that we can perform more tasks with fewer people present.

- Øyvind Svaland, Veidekke

IMAGE: Spot and the Veidekke team in a cordoned off area in the tunnel.

Safety

“There are many benefits of Spot, particularly related to safety for people, autonomous repetition of tasks and increased flexibility in our operations, ensuring that we can perform more tasks with fewer people present, “ says Svaland, pointing out another benefit of Robots – that they can operate in areas that are unsafe for people. This opens up another window of opportunity for improvement and increased efficiency – Spot can make scans in areas that have been recently blasted or lined with concrete without any concern for personnel safety.

Vestfoldbanen / Drammen-Kobbervikdalen – UDK 01 construction site

BuildingPoint joined Svaland and the project team in charge of scanning and other tasks at the UDK 01 site for the Vestfoldbanen/Drammen-Kobbervikdalen – a railway tunnel project for Bane NOR to put Spot to the test. Naturally, Spot has gone through extensive testing in product development, and there are already live projects around the world, but for Veidekke it is important to get down to business - put the tools in hands of the people on the ground and validate the entire process between different project diciplines.

Interaction between software and hardware

“The interaction between software and hardware and the flow of data is very important,” says Svaland, and explains that Veidekke has ambitions to continue to push the boundaries to find ways to make systematic improvements for the industry.

”Veidekke can take the lead with the help of our suppliers, such as Trimble and BuildingPoint, which also delivers tools like Tekla and Trimble Connect,” Svaland says. He goes on to admit that he expects success with robotization, but that there are still hurdles to overcome. ”We certainly anticipate a lot of challenges when starting with robotization, but we will never learn if we do not start!”

This article is also featured in Norwegian at Veidekke’s website, here

MORE CUSTOMER STORIES