Digital Construction in practice - Danske Bank Headquarters

Per Aarsleff A/S submitted the Danske Bank Headquarters project to the Tekla BIM Awards 2022 competition. The jury in BuildingPoint Scandinavia was very impressed and awarded the 2nd place in the regional competition to the project team!

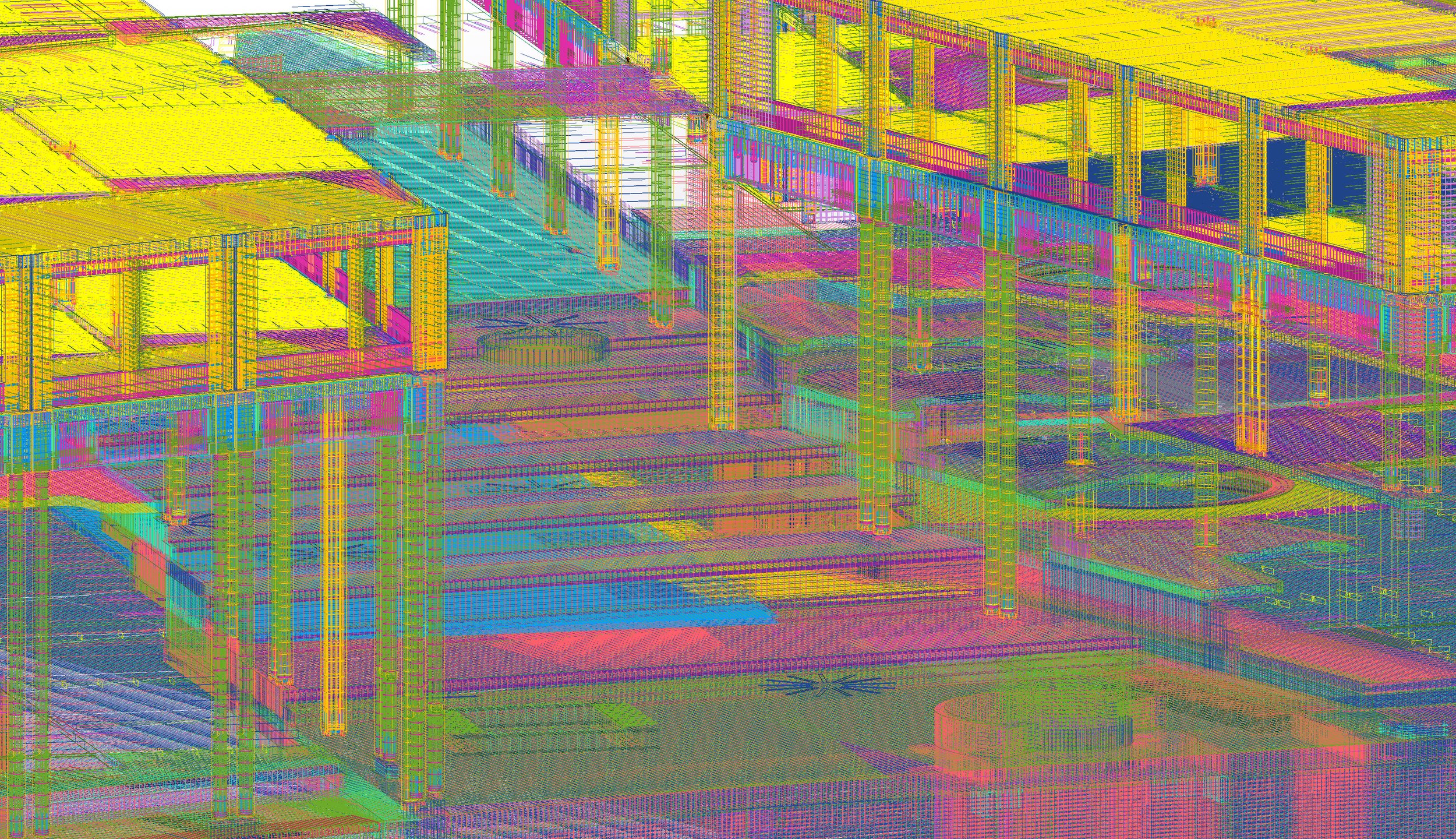

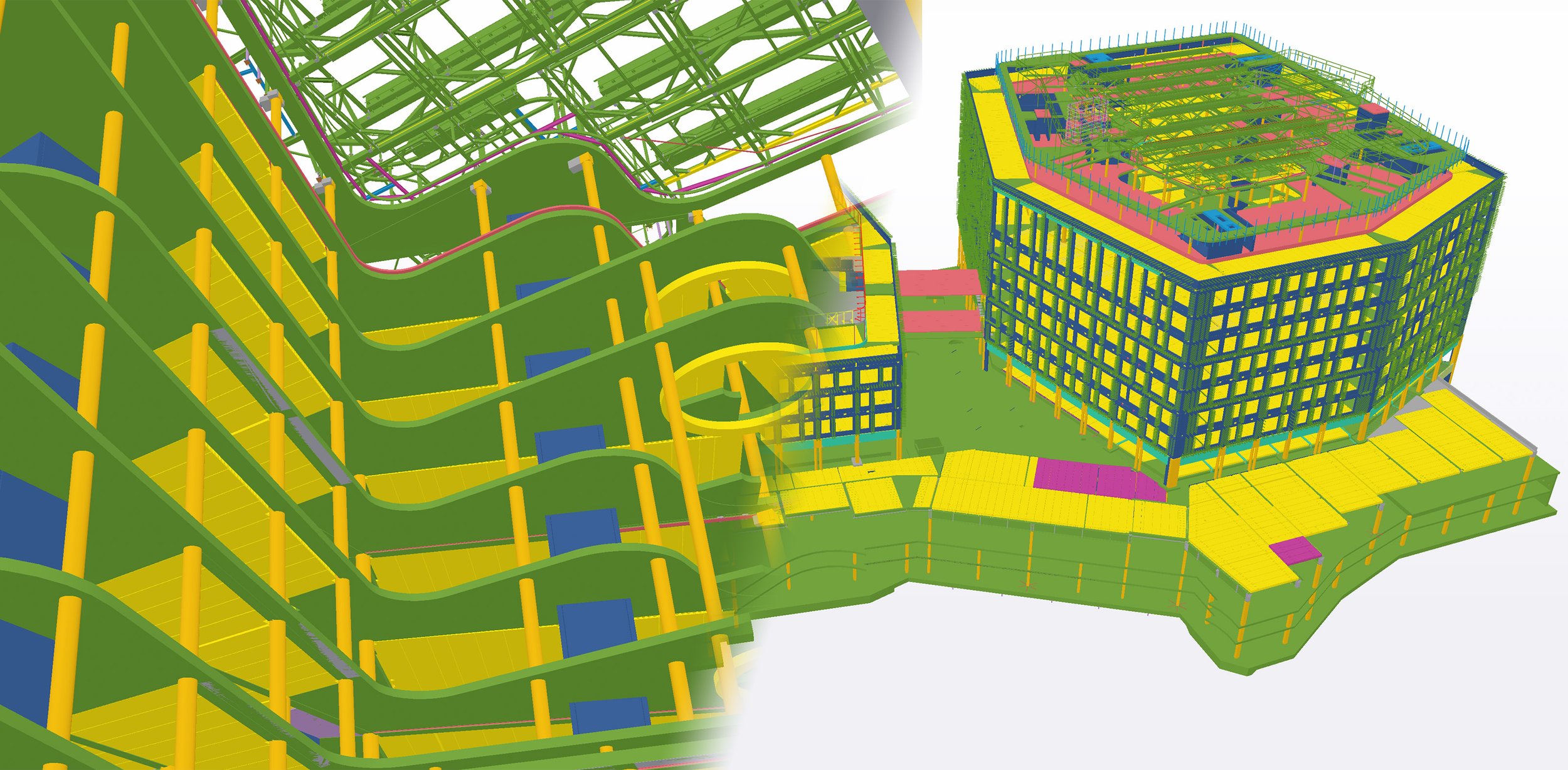

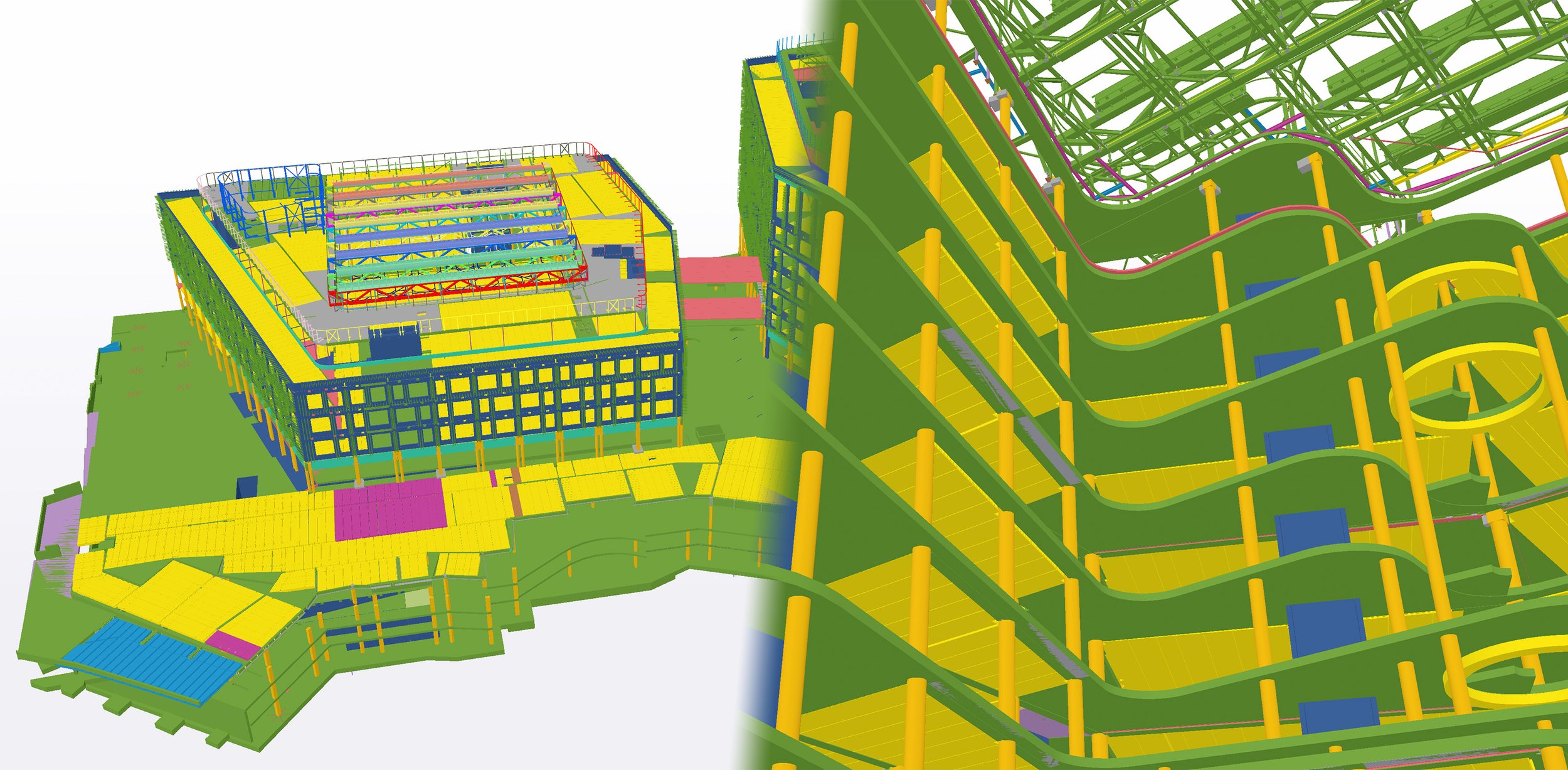

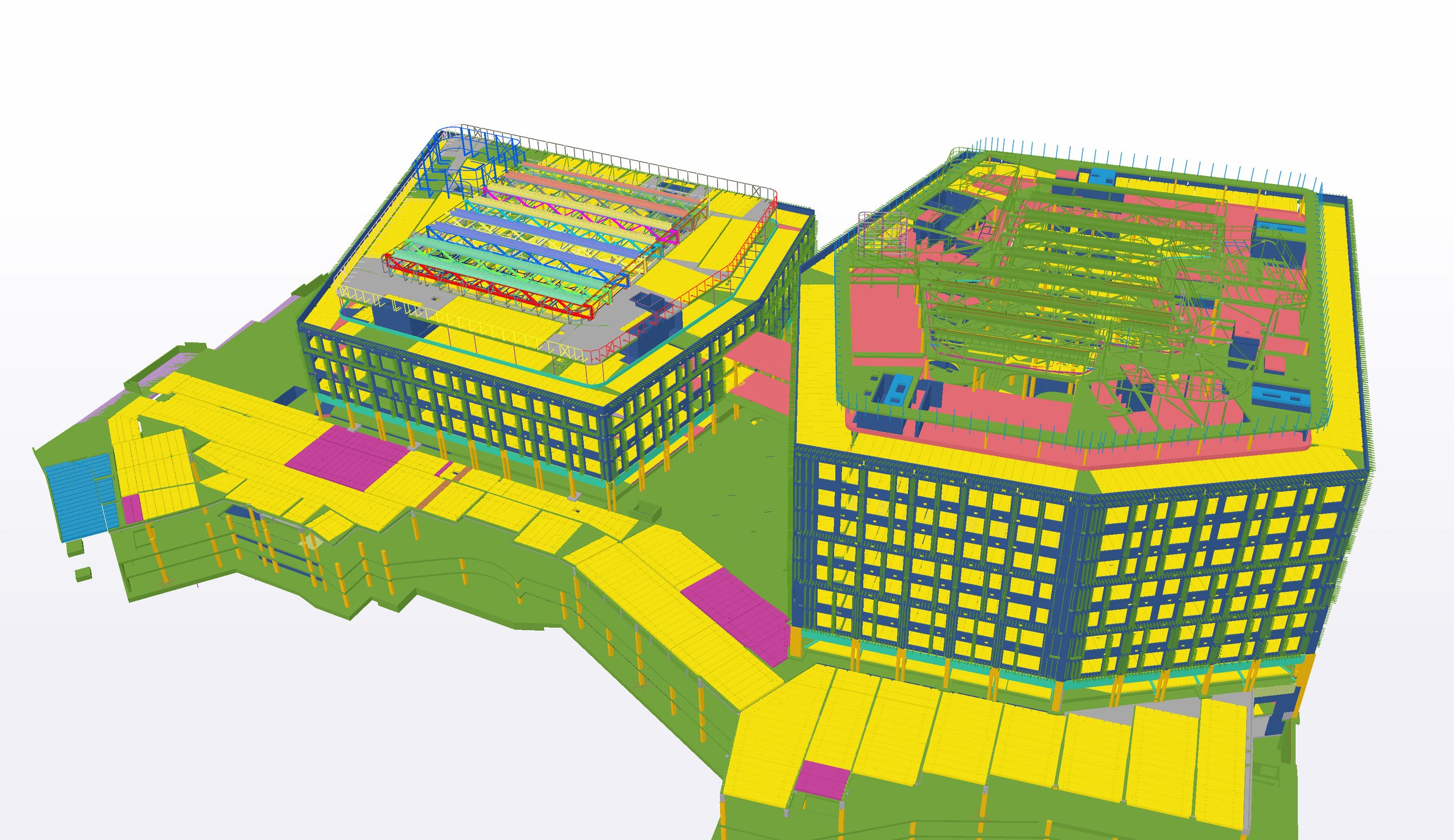

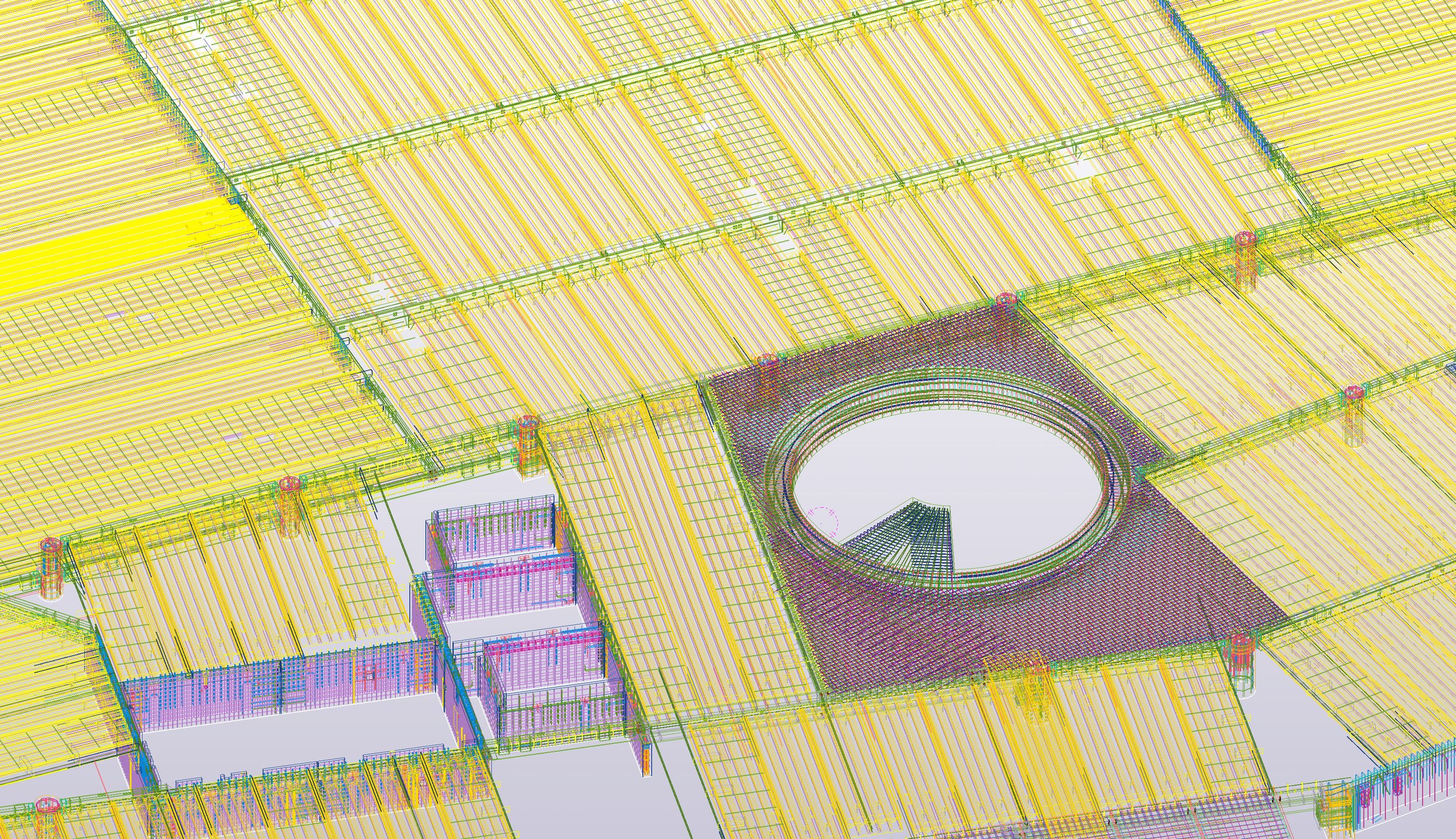

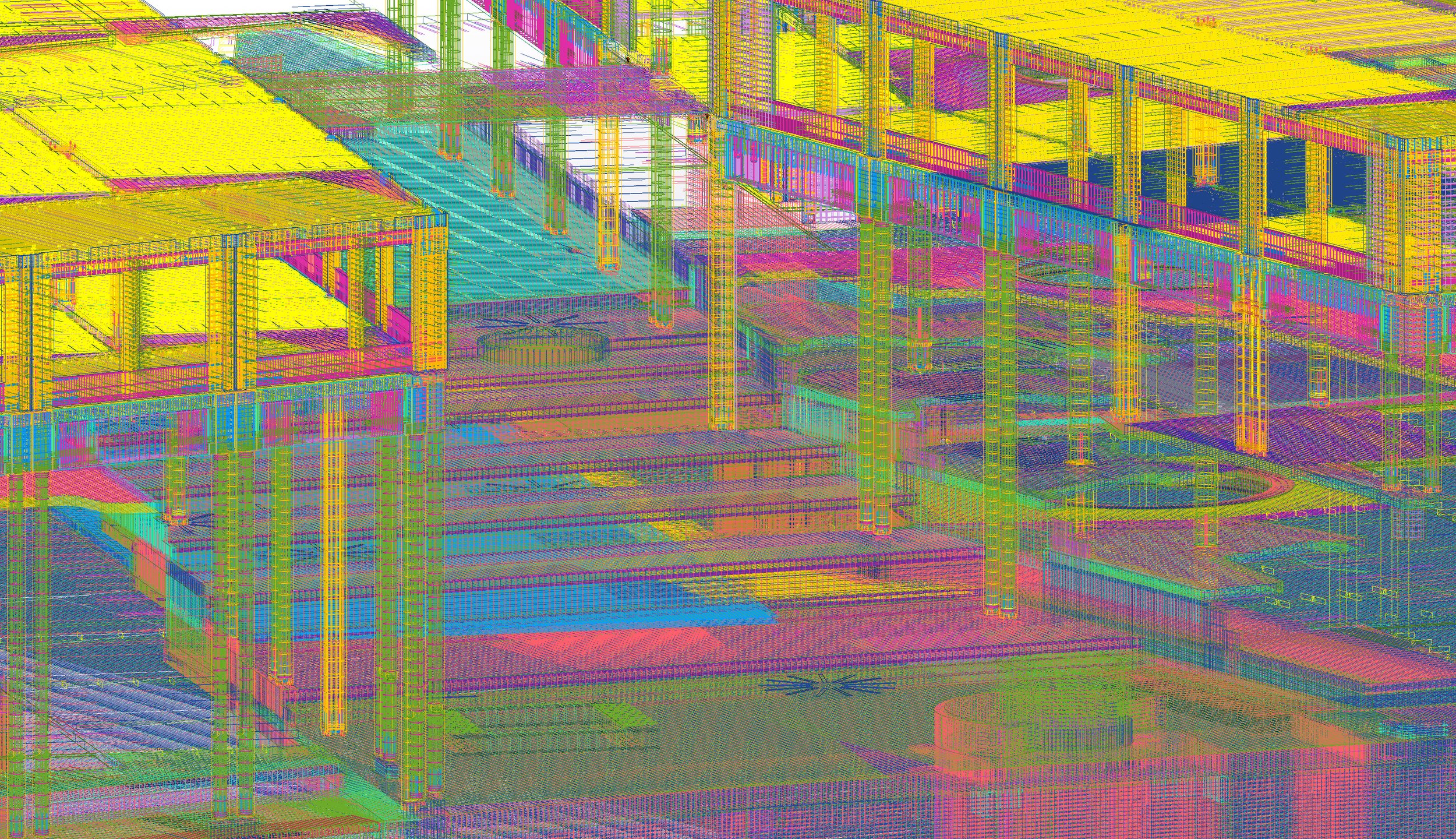

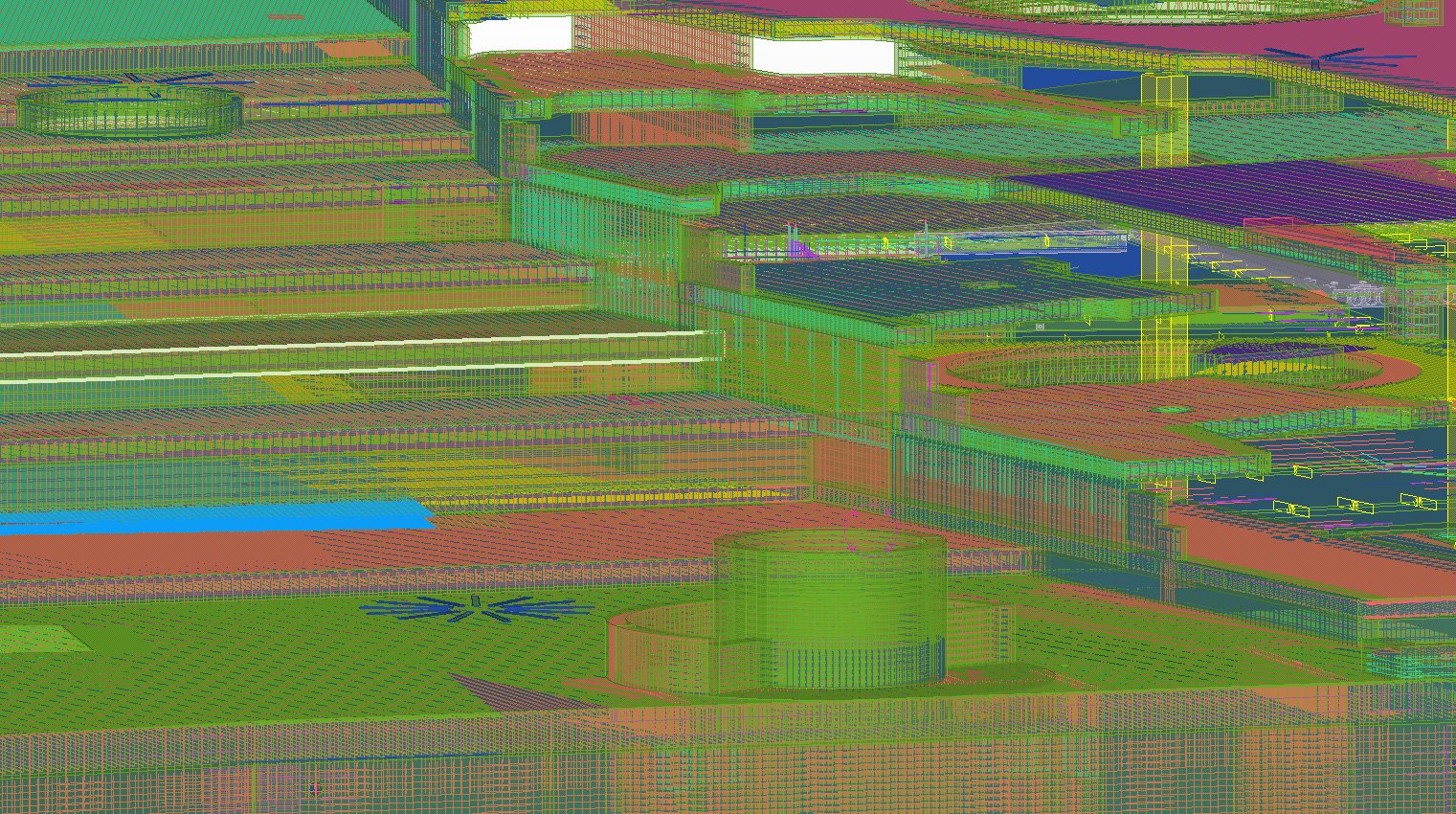

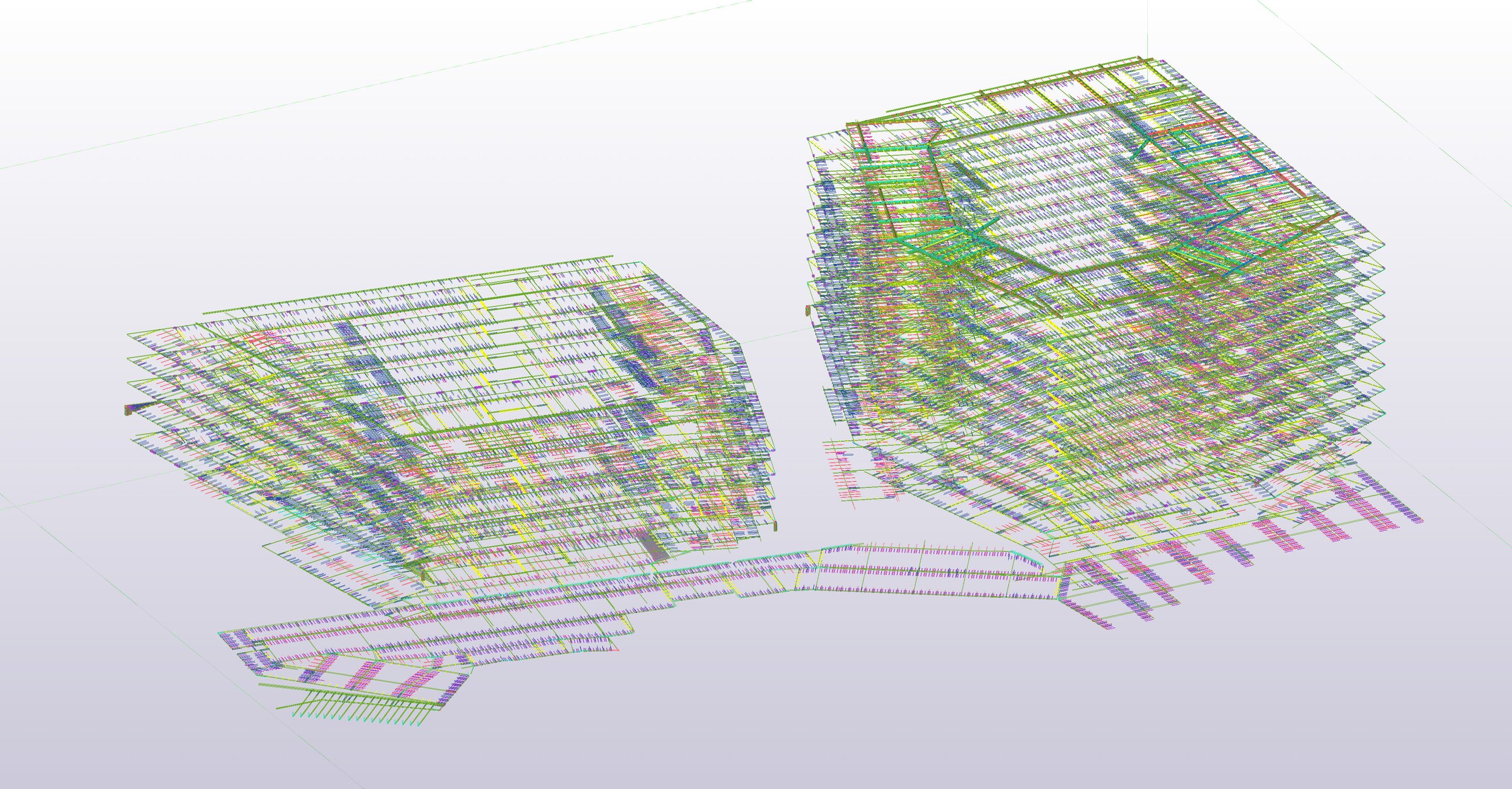

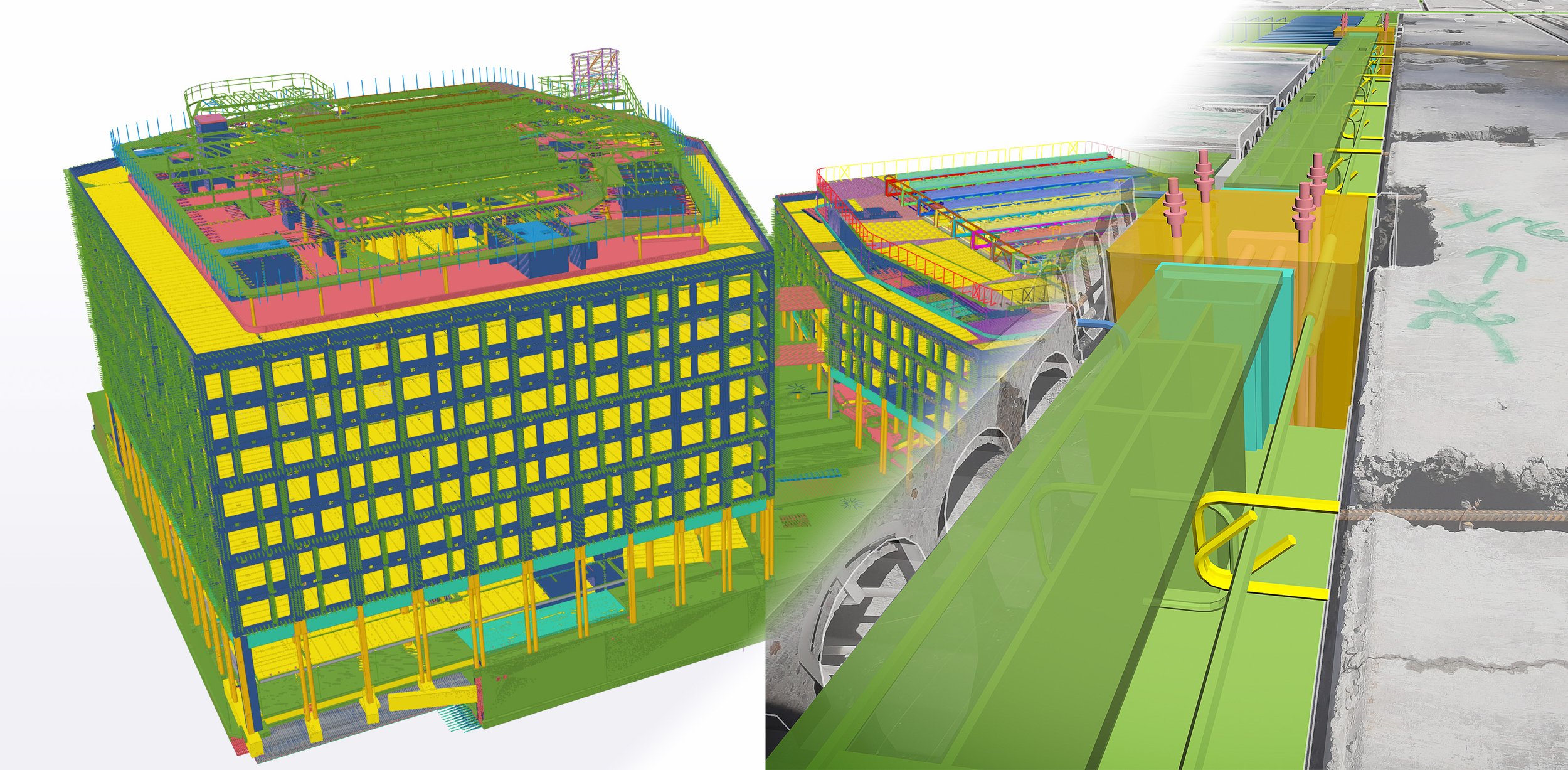

By taking full advantage of the possibilities in Tekla to model everything in detail (LOD 400), including fully detailed concrete reinforcement, the project was essentially built twice - first digitally, then physically. This approach allowed for high degree of insight into possible build problems in the digital domain and thus significantly reducing or even eliminating issues to deal with on-site.

Recognizing that this process only works if the whole value chain are involved, the project has put great efforts into the collaboration between suppliers, consulting team and external execution team.

The project serves as an example of world-class digital construction according to the jury.

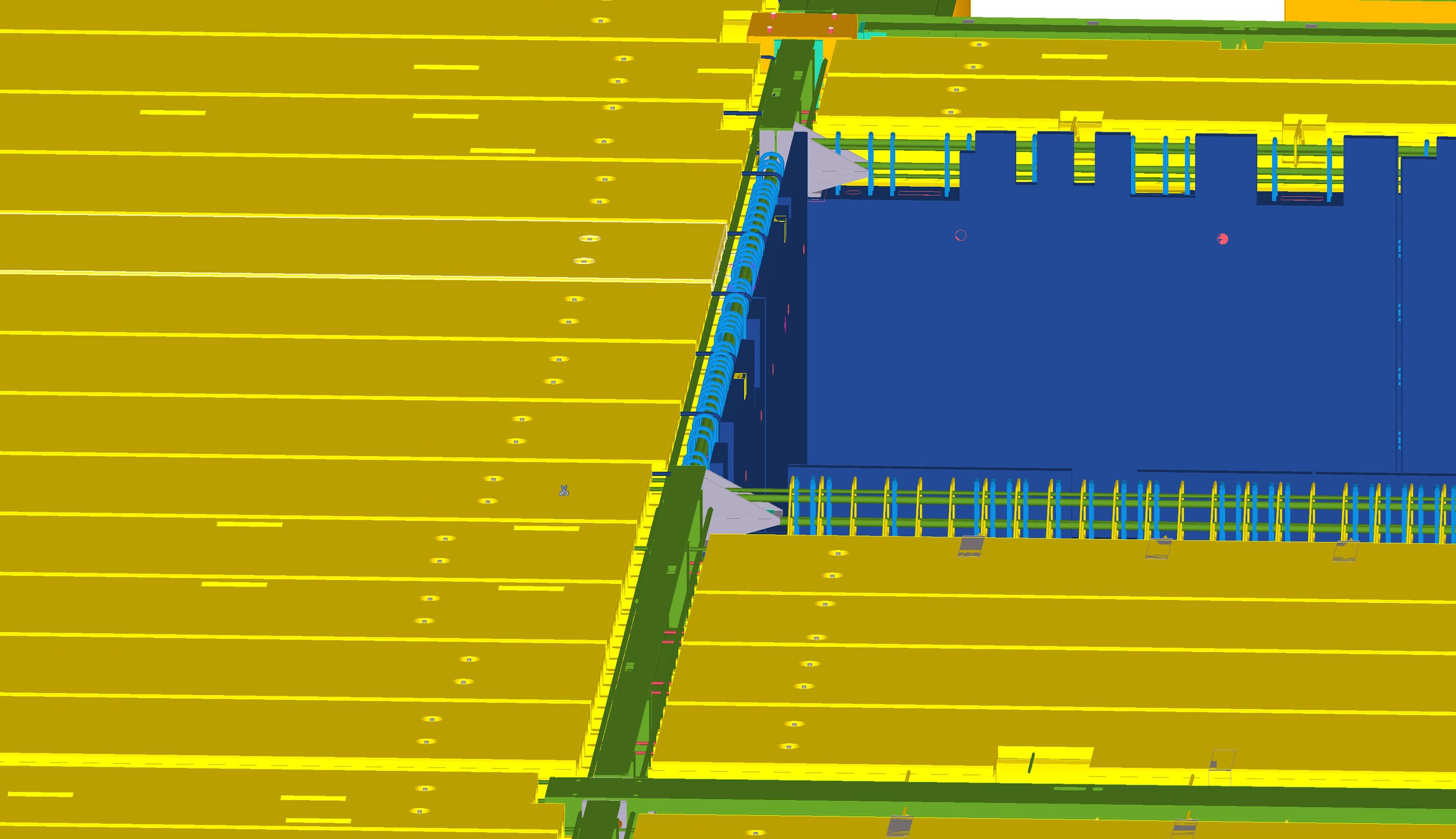

VIDEO: Danske Bank Headquarters BIM model in Tekla. Courtesy of Per Aarsleff A/S

Design and Build

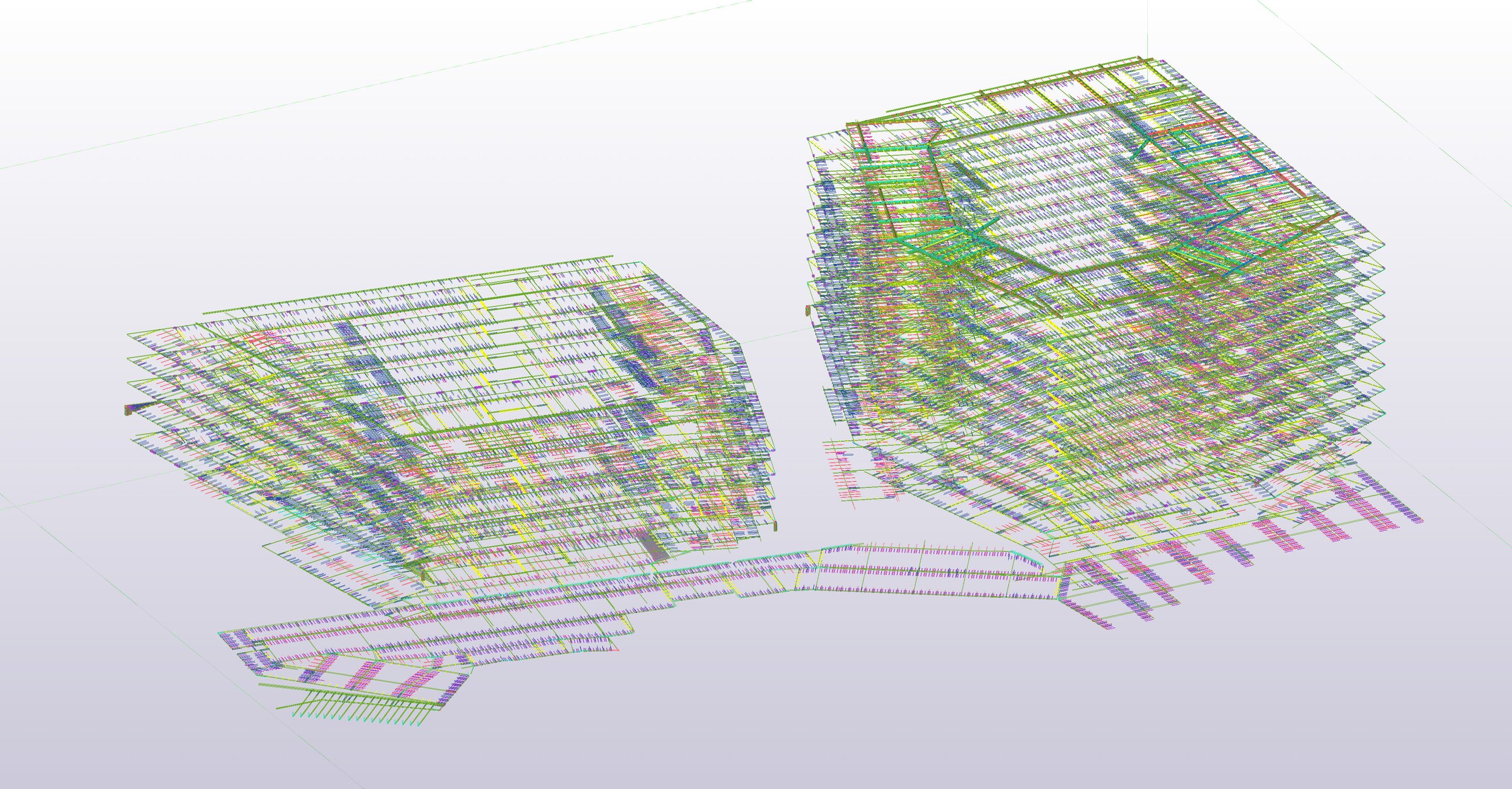

The project (TA03a) is a design and build contract. The project had a very complex installation system, not unlike hospital projects or similar. As design and build contractor, Aarsleff had great focus on planning. Wasting time trying to find solutions on the site during the execution phase is a luxury that has no place in these kinds of project.

Building the project digitally before starting the physical construction job allowed the team to identify possible problems and find solutions in the BIM model before the execution phase. This leads to a good workflow on the physical construction site.

“

When we put it together virtually at first, we can optimise and find the good solutions in advance.

- Àstridur Elin Àsgeirsdottir, Per Aarsleff A/S

“

It gives our own production team an overview and a far better understanding of what is going on both internally in the specific building element that you are working on and in the interfaces to the objects around it.

- Erik Stender Hornstrup, Per Aarsleff A/S

VDC in the execution phase

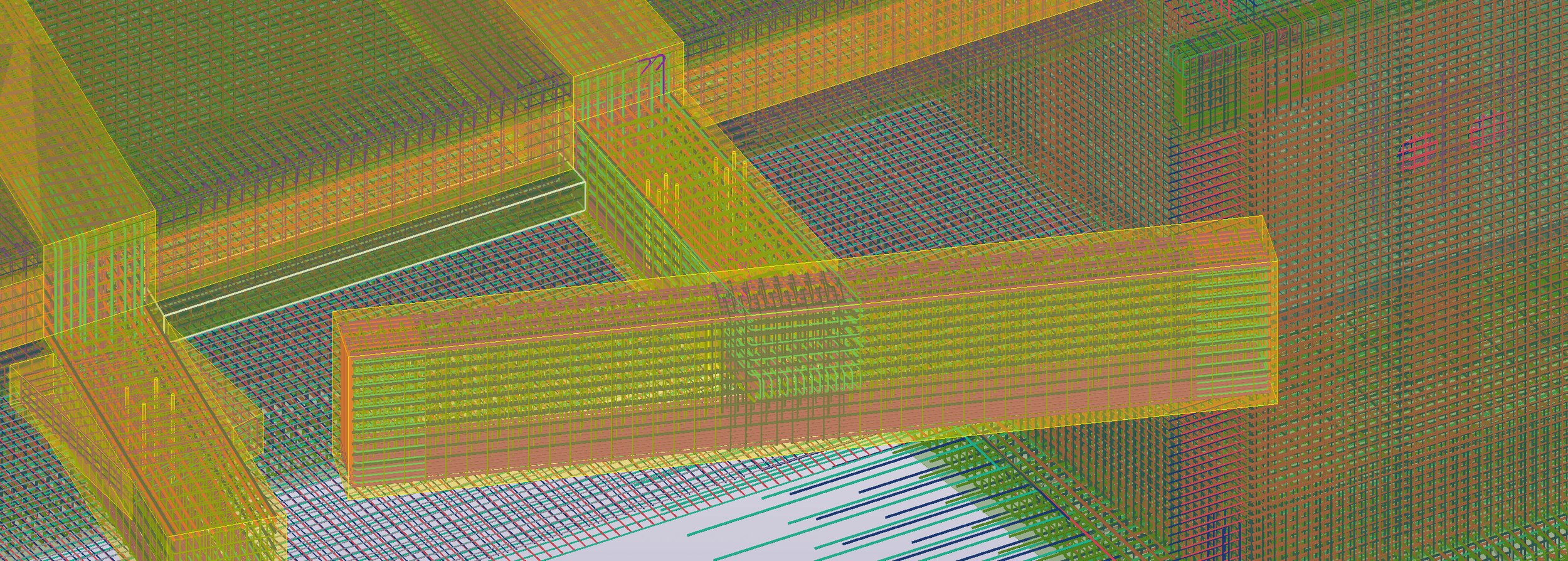

For the construction model for Danske Bank’s headquarters, Aarsleff provided digital reinforcement and digital joint reinforcement modelled in Tekla by Aarsleff’s production specialists. To succeed with digital reinforcement and joint reinforcement, it requires highly detailed BIM models and good collaboration with consultant, suppliers and subcontractors.

The consultant delivers BIM models in LOG 325 (Level of Geometry), and the suppliers and Aarsleff complete the models for execution and LOG 400. This means that Aarsleff must allocate in-house resources and ensure that the steel suppliers they choose make their production basis in BIM.

The steel supplier (Give Steel) and the element supplier (Spæncom) use the consultant’s model as production basis. It’s important that the models are applicable for execution or for basis for execution and that they are delivered in IFC format.

All suppliers of the load carrying skeleton structure in this project used Tekla for their execution project.

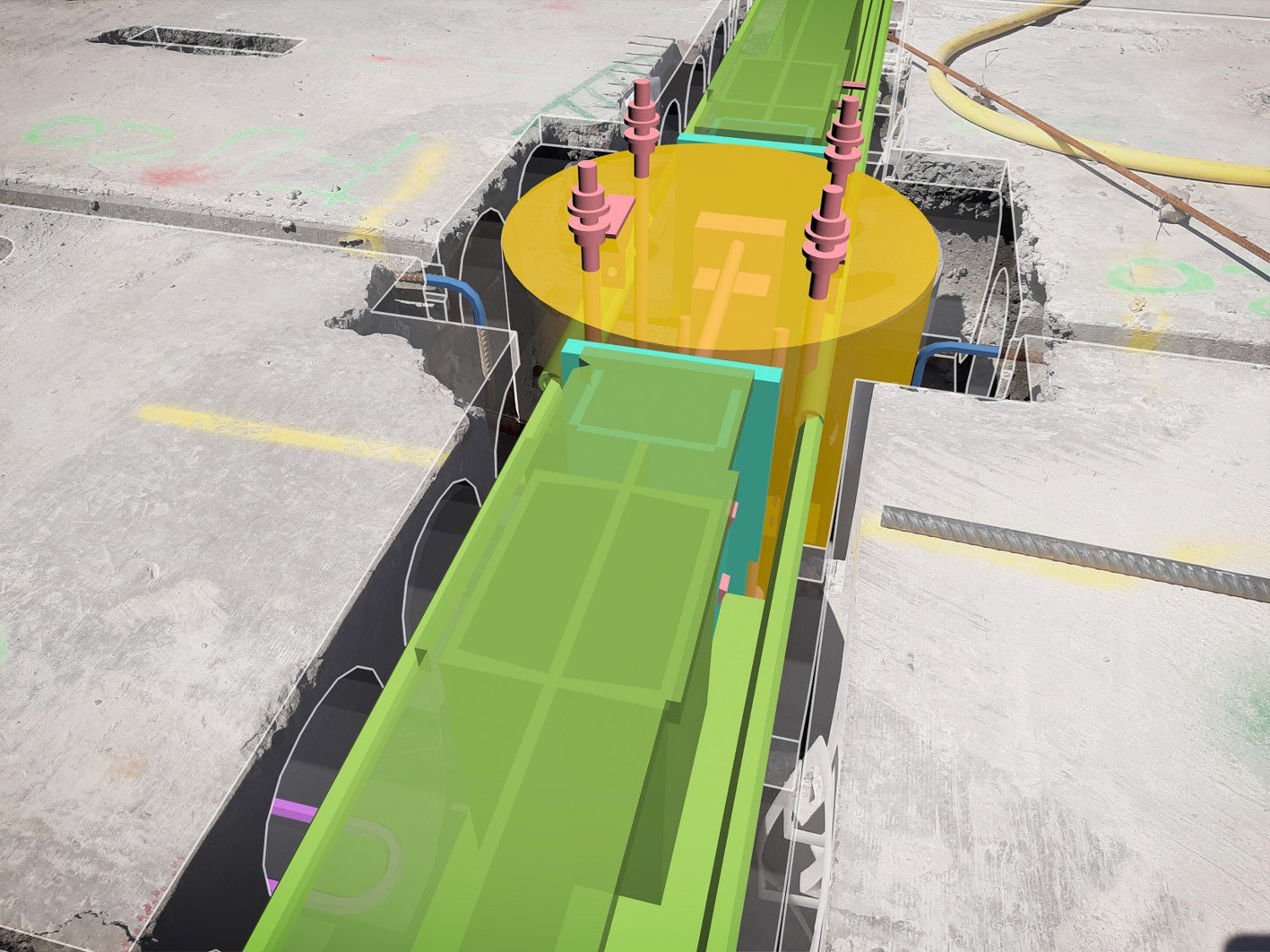

In addition, all specialist fields, including construction model and installations, are scanned weekly to ensure correct execution in relation to the designed BIM model. Aarsleff also use software which can compare the scanning point cloud with the designed model and in this way ensure that what is built comply with the model. In case of deviation, the project team can agree in advance whether this shall be corrected on the site or in the models, depending on what the analysis of the consequences of the deviation shows.

Why did it go well?

According to Aarsleff it’s important to have a close collaboration with suppliers, consulting team and external execution team in order for this process to create value.

Many challenges will occur, like discovery of detailing principles described in the design phase which cannot be built. In such cases Aarsleff can redesign the detailing, so it’s practical to build.

By having close coordination with their suppliers through Trimble Connect, Aarsleff are able to deal with problems and find solutions at an early stage, before the suppliers start producing the elements in the factory.

Thanks to a high detail level and dynamic coordination, Aarsleff’s team is able to take quick action on the basis of information that is aligned with the suppliers, while also focusing on the whole project and not just solving issues in isolation. Whether the action should be taken in the factory or on the site can be planned in advance and approved by the consultant, so that it can be coordinated in the production on the site, and in this way they can avoid production unplanned stops and frustration. This gives a better overview and understanding for all parties when everything is collected in a BIM model.

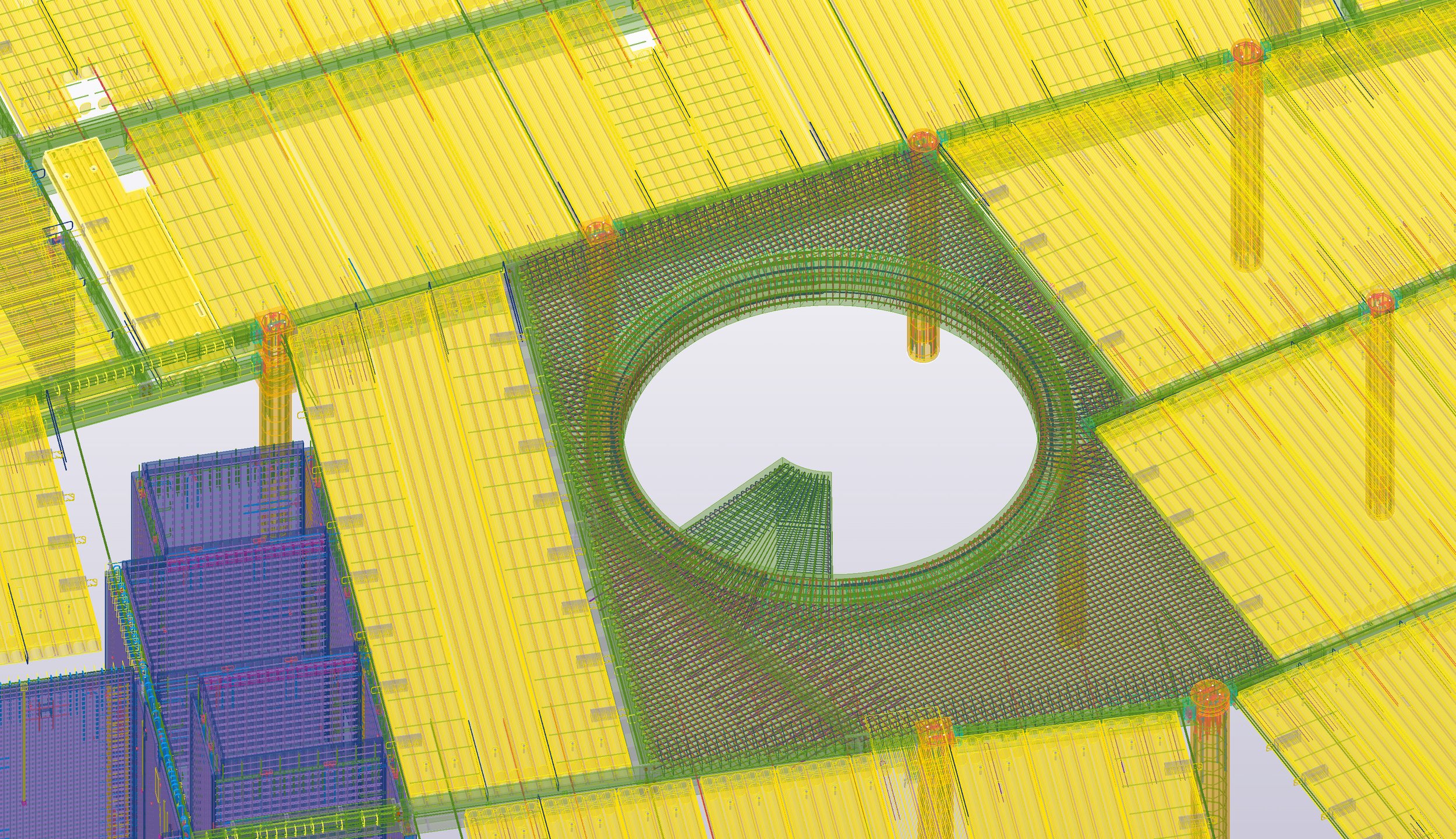

The common model, where everything is modelled down to the last bolt, weld or reinforcement rod, makes the cross-disciplinary coordination between subcontractors more efficient, as Aarsleff get a better insight into connections and interfaces. This coordination is crucial and helps reduce production stops considerably, according to Aarsleff.

The correct information at the right time – for everyone!

To Aarsleff it is first about creating an improved workflow, more efficient processes and reducing production stops on site.

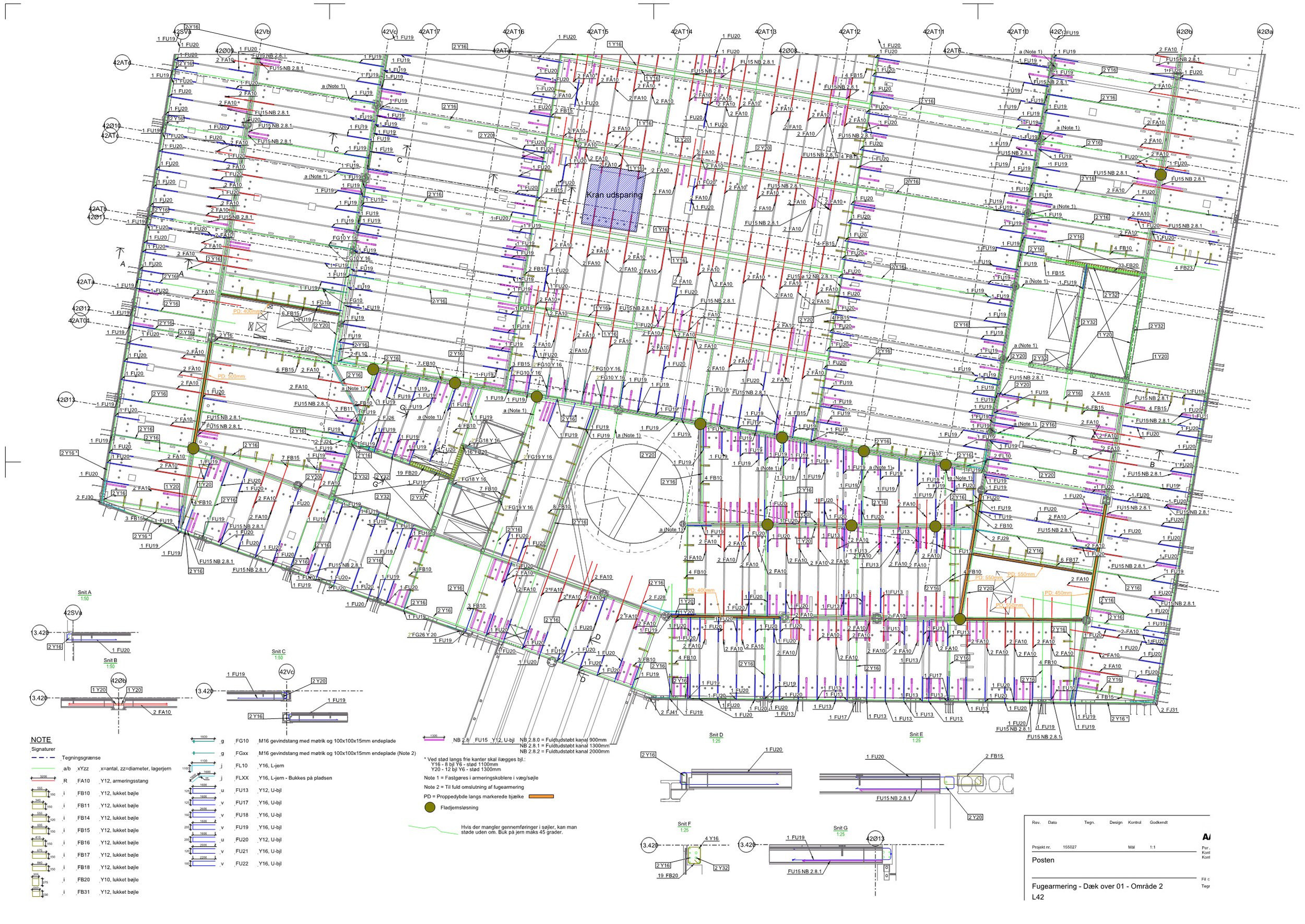

They model the reinforcement in 1:1, and order the reinforcement directly from the model to the reinforcement supplier’s systems. But the most comprehensive work in connection with digital reinforcement is coordinating and ensuring that the right information in the right format reaches every employee on site.

The highly detailed models are only valuable when the information reaches the individual worker on the site while building.

The workers need to have a overview of the individual in-situ casting so they can easily plan their work and move the right amount of reinforcement to the right place to be able to install the reinforcement.

Therefore, the CU drawings are essential for the workers, providing them with a quick overview of reinforcement types, amounts and assembly.

Having access to the Trimble Connect model as well as to the detailed drawings from Tekla on site has provided quick access to the information required.

The model provides a quick understanding of the complete structure and of how it is to be built together. By having access to drawings at the same time, the workers will get a quick presentation of the exact information they need for installing the reinforcement.

“

Aarsleff’s design team can, in close cooperation with the site managers and foremen, get a quick visual understanding of the reinforcement design and optimize it to improve the flow on the production on site as much as possible.

If unforeseen challenges arise, these can be communicated quickly and visually to enable quick decision and action to solve the issue.

- Erik Stender Hornstrup, Per Aarsleff A/S

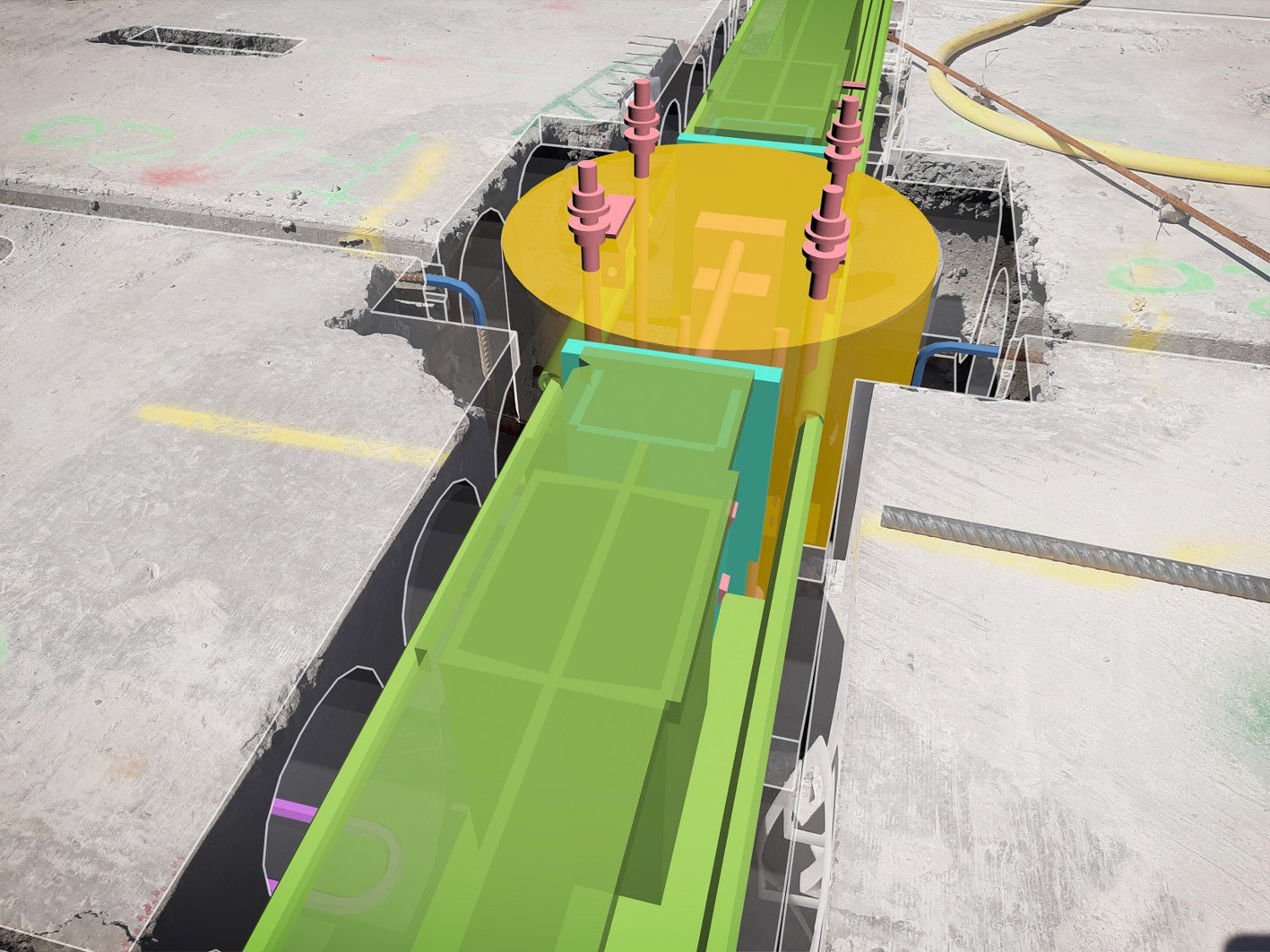

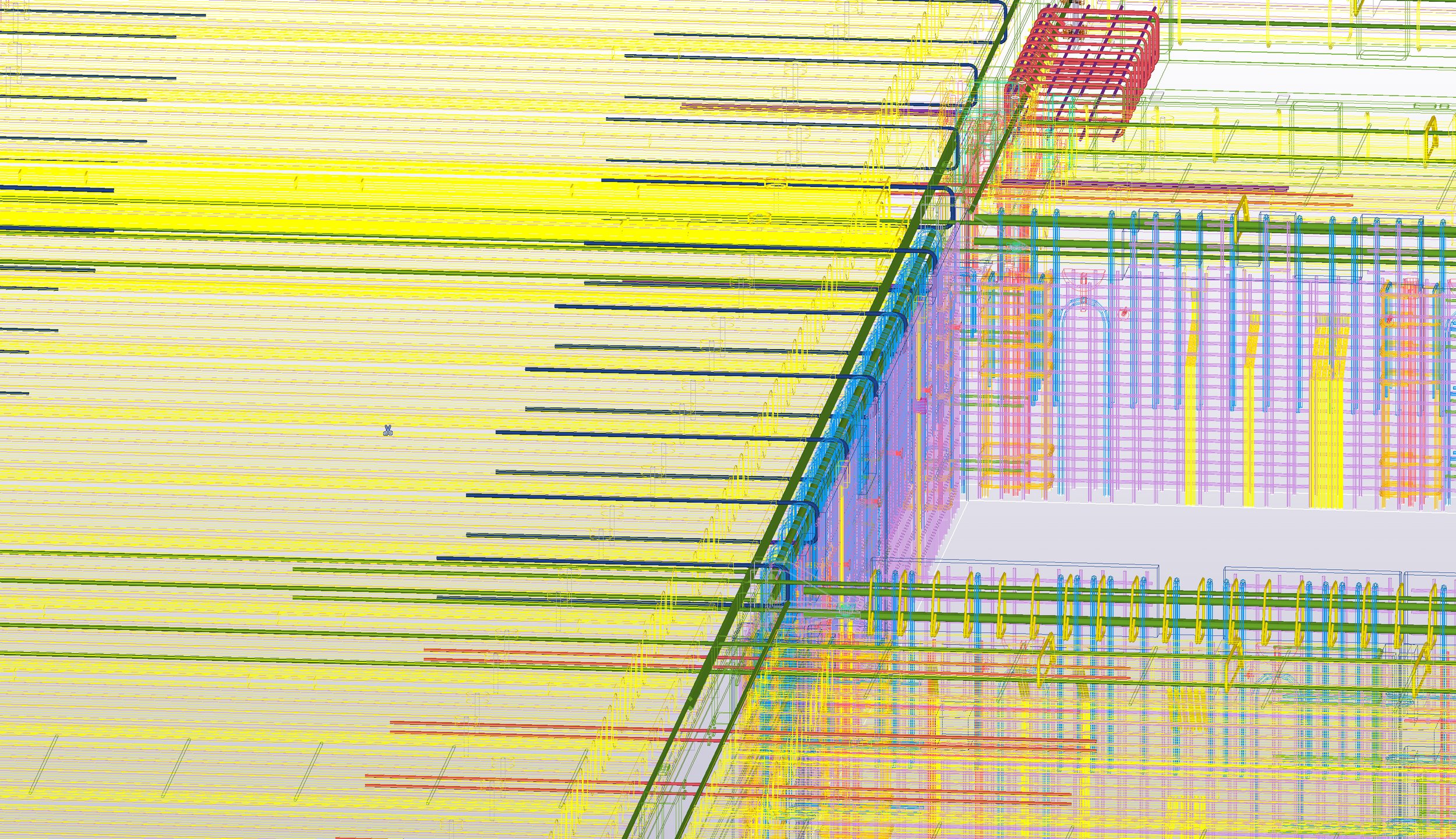

IMAGE: Detailed reinforcement modeled in Tekla

Build virtually – then build physically!

Digital reinforcement modelled in 1:1 in a Tekla model has been standard at Aarsleff for more than six years, and the company have many employees who are specialists in digital reinforcement.

Joint Reinforcement is one of Aarsleff’s new services and was first tested at the Danske Bank project. Joint Reinforcement is not just about modelling or ordering of reinforcement (or even the building component called “joint reinforcement”); it is about coordination of all details before execution thereby creating improved workflow, efficiency, reduction of production stop and ad hoc work on site, and not least reinforcement waste.

This mindset and process has created a lot of value and the project have significantly reduced the amount of production stops. Based on this experience The Joint Reinforcement service are being applied to many of Aarsleff construction models.

Therefore, these services are a win-win for everyone as they are time-saving, cost-efficient and create improved sustainability on their projects.

- END -

About the project

Project name:

Danske Bank Headquarters

Project category: Headquarters

Project location: Denmark

Type of contract:

Design and build contract

Design start: 2015

Handing-over: April 2023

Finance: DKK 3.2 billion

Size: 110.000 m2

Concrete: 35.000 m3

BIM model in numbers:

Reinforcement: 7,216,331 kg

CU drawings: 568

GA drawings: 98

Consultant’s models: 3

Supplier’s models: 117

About Tekla BIM Awards

As regional reseller of the Tekla software, BuildingPoint Scandinavia organizes Local Tekla BIM Awards in Norway and Denmark during spring 2022 followed by a Global competition in the fall of 2022.

The winners of Local Tekla BIM Awards 2021 and 2022 are eligible to enter the Tekla Global BIM Awards, the biennial global final.

About Tekla Software

Tekla software is developed by Trimble. Tekla is is Building Information Modeling software used in countless project world-wide.