NCC improves Cast-In-Place design and construction by connecting the digital model with the real world

Regardless of material choice – whether it is wood, steel or concrete – finding design errors at the construction site is undesirable. Even small design flaws found at a late stage can cause significant delays and add unplanned cost. If you include the potential knock-on effects of the project schedule to the big picture – one can see why contractors are motivated to spend efforts to improve processes and ensure that the design is correct from the start or corrected as early as possible!

BuildingPoint Scandinavia met Process and Innovation Manager Casper Hertz Nielsen in NCC Danmark A/S, and the project team at the Kronløbsøen project in Copenhagen to learn how NCC addresses this.

The challenge

BIM is well established since many years back, but 3D models are still used as basis for 2D drawings in many projects. Although NCC has made the transition to 3D modelling many years ago, the company is constantly looking for ways to harvest more value from the 3D models as new technology becomes available.

“Some of the challenges we have in the industry now are related to communication and sharing of the 3D models we make”, says Casper Nielsen and goes on to explain that they always use the 3D models to discuss design and plan production with the craftsmen responsible for construction on the site. This creates a design/build feedback loop that increases quality. They would normally bring the team into the barracks for regular discussions about the design, using the 3D model as a basis.

“What we are proud of in this project - what we are succcessfull with - is the extensive use of the 3D model,” Nielsen says and adds that a major part of the success is that the people who make the 3D models also have extensive experience from production.

The next step to ensure smooth production and early identification of problems is to make the 3D models easily accessible for the team on site. With PCs in containers out on the construction site, they make the 3D model even more accessible for ad-hoc reviews. The on-site review is far more efficient without the need to walk or drive to the project barracks.

PICTURE: NCC shows how they have made a “BIM Station” or “BIM Kiosk” with Trimble Connect in the container at the construction site.

Rebar detailing and collaboration

PICTURE: Cast in place concrete structure, real world VS digital world in Trimble Connect

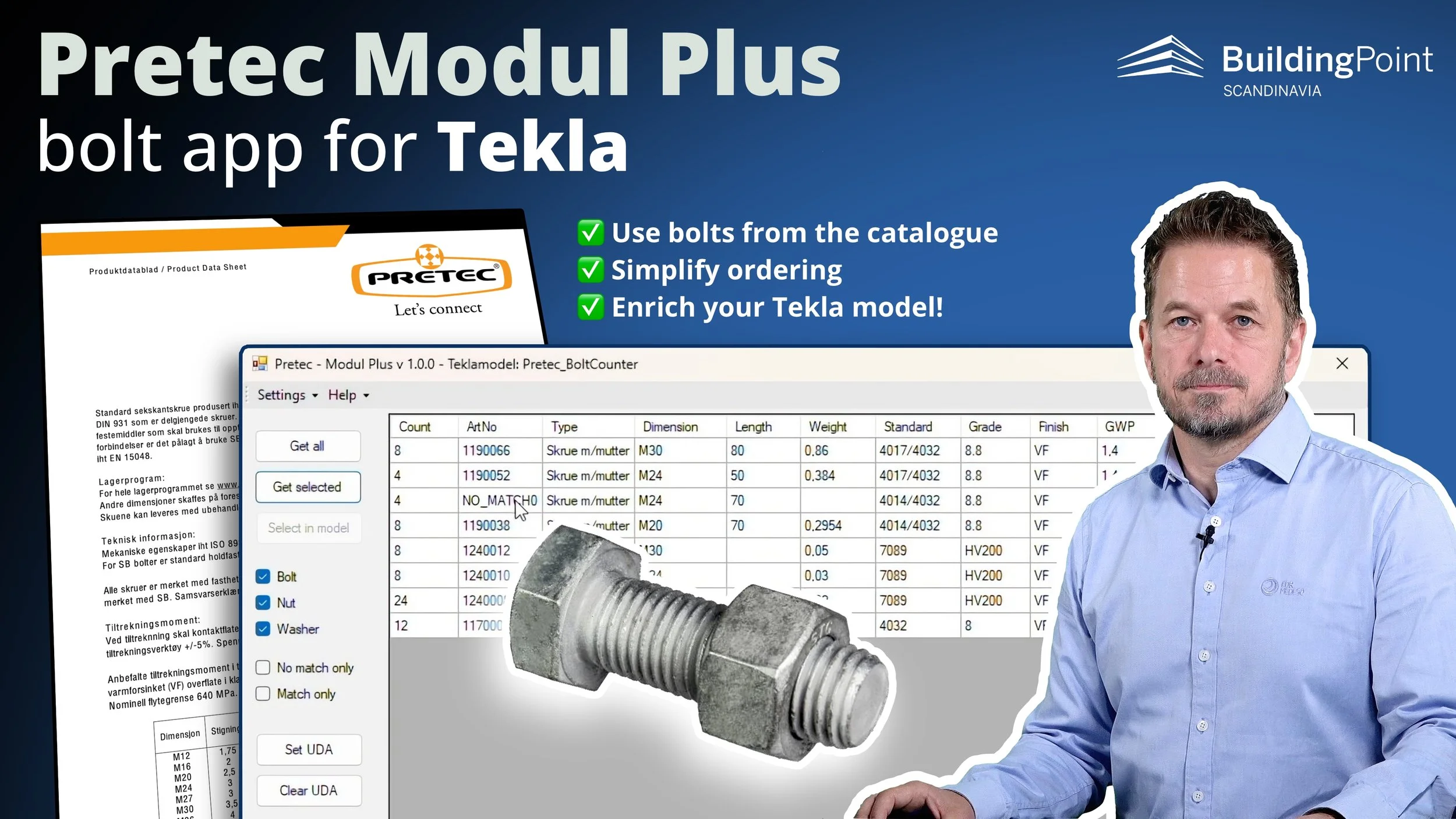

“The program we have used to model this reinforced concrete structure is Tekla, and that is because Tekla is very strong for rebar detailing. The program we use to display the 3D models in the containers is Trimble Connect.”

Using this cloudbased software, it is easy for the designer to upload the models so that everyone on the site has up-to-date models to work from and point out possible challenges with the design.

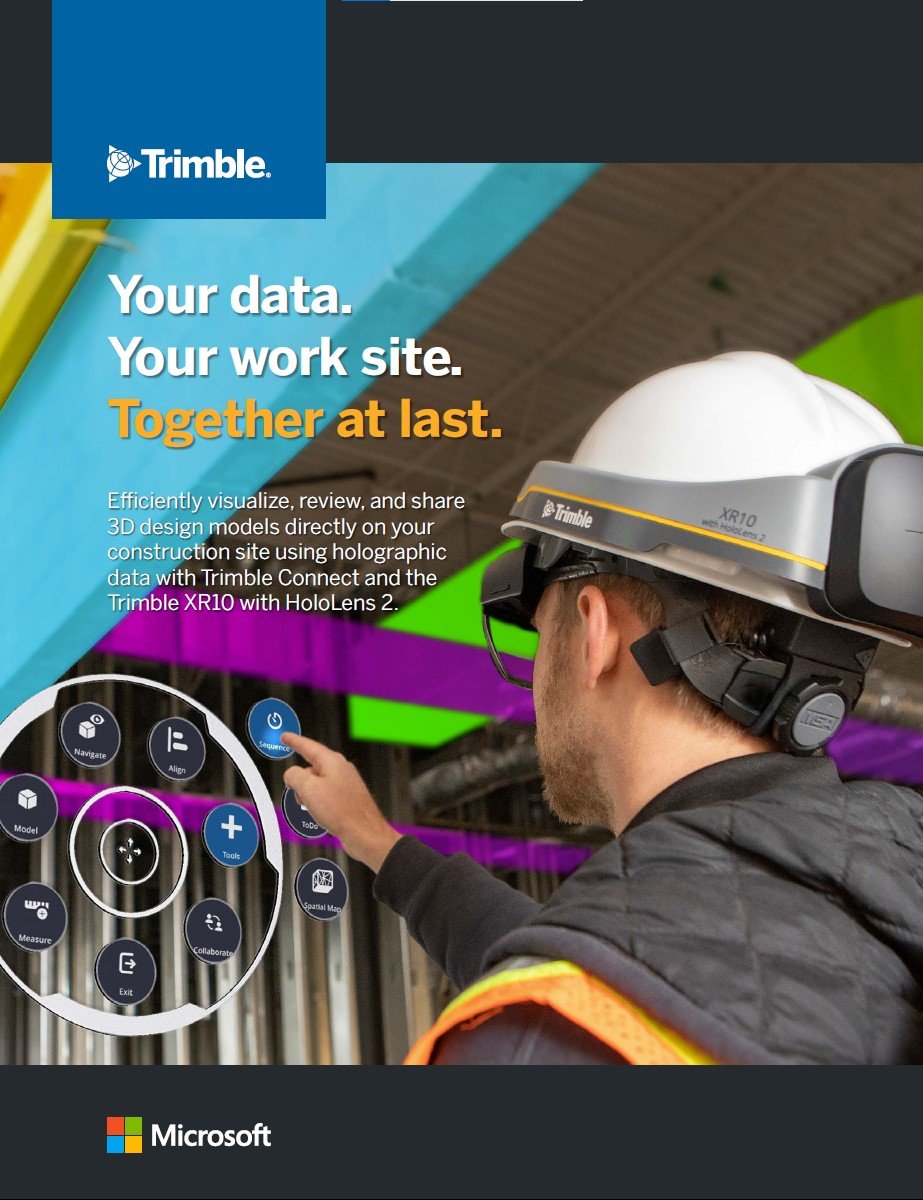

Augmented Reality

Trimble Connect makes the 3D model available on the construction site from a phone, a tablet, or a PC. With the new Trimble Connect AR, that displays the 3D model on top of and aligned with the real world, the project team may possibly expand the use of the 3D model to spot mistakes or potential improvements even more easily than before. Casper Nielsen agrees that this augmented reality indeed a useful feature in many cases, but he has even higher ambitions for this technology - namely Mixed Reality, or “3D in 3D” as Nielsen calls it.

VIDEO: Trimble Connect AR. Augmented Reality on a phone, rebar details from Tekla overlaid on the real world.

Mixed Reality – 3D in 3D!

“Our digitization has helped us a lot to make us more efficient and find errors and mistakes BEFORE we start production. But how do we include the production ...so that it also becomes more digital?” Nielsen asks rhetorically. He continues to explain that one of the challenges is the fact that the 3D model is still used in a «2D way» , as long as it is viewed on a flat screen.

“We have to find a way to move away from this 2D sharing of the 3D model… we must have 3D sharing of the 3D model,” he states firmly. Nielsen continues to ask for much better integration between reality and their digital models, which would allow NCC to use the 3D models even more actively during production.

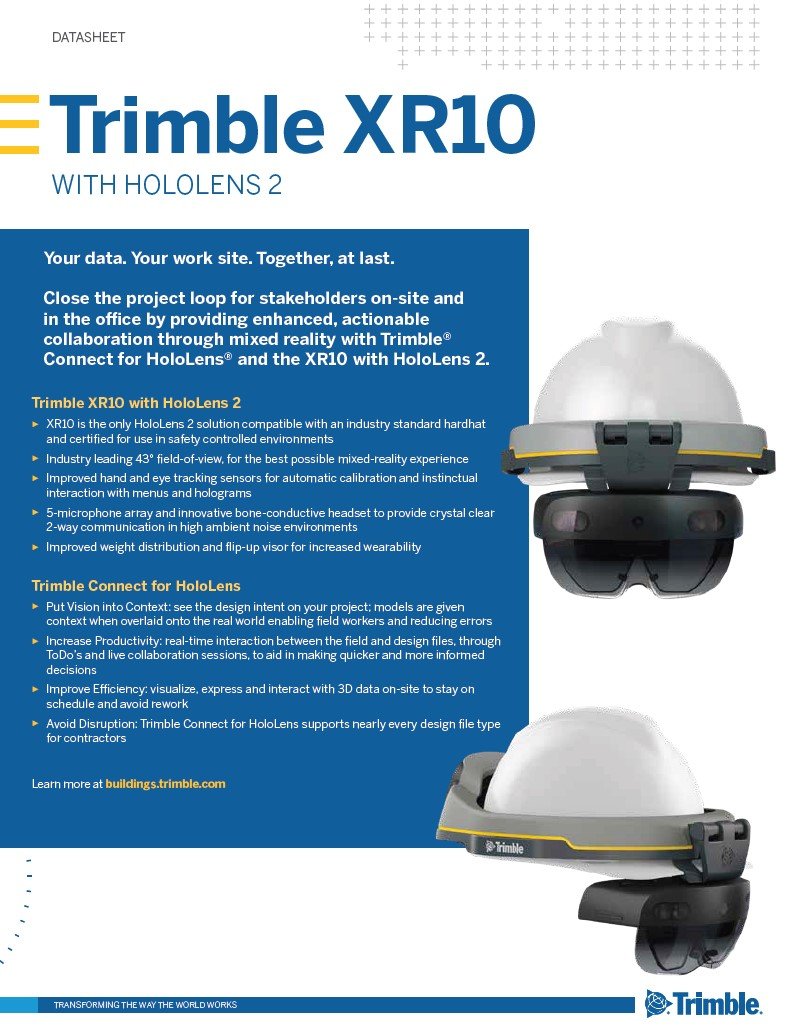

The term MR, or Mixed Reality, is sometimes used to describe the “next level” of Augmented Reality (AR). The term Virtual Reality (VR) is achieved if the user/viewer sees the 3D model with both eyes in perspective, while Mixed Reality takes this one step further and mixes the VR with the real world, giving a full 3D experience that blends the digital model with the actual construction site.

Using the Trimble XR10 with Hololens2 from Microsoft, the user has a safety helmet, with Mixed Reality goggles integrated, leaving the operator to work with both hands free! Although the technology for this is mature enough to work well, NCC challenges their design and construction teams – and the technology vendors – to develop workflow and software that supports people in accessing the correct data at the right time to make the technology usable in daily operations on a large project like Kronløbsøen.

“

We have to find a way to move away from this 2D sharing of the 3D model… we must have 3D sharing of the 3D model

- Casper Nielsen, NCC

VIDEO: Screen capture from the Trimble XR10 with HoloLens2, testing by NCC at the Kronløbsøen project in Copenhagen

Total Stations – taking the BIM model into the real world

Nielsen tells us that he believes the Mixed Reality technology, and the processes around it, is a natural step for the NCC team to progress their work processes on complex cast-in-place projects. He adds that Total Stations are part of the technologies that they use today:

“You can click on your digital model, and the Total Station will show you a laser dot where you have the corner of the structure, for example,” and says that even as simple as this sounds, it is a very powerful way of taking the digital BIM model into the real world!

“What we are proud of in this project - what we are succcessfull with - is the extensive use of the 3D model.

The program we have used to model this reinforced concrete structure is Tekla, and that is because Tekla is very strong for rebar detailing. The program we use to display the 3D models in the containers is Trimble Connect.”

Casper Nielsen, NCC Danmark A/S

Future perspectives and focus

Before concluding the day of testing MR and AR, Nielsen says that he will continue to look for ways to align people, processes, and technology:

“I believe that in the future we will have a much better integration between reality and our digital models, which will allow us to use them much more actively.”

Before thanking the NCC team on the construction site for their work on the project, but also for allowing us to test new technology in the project, Nielsen poses a challenge for the suppliers of digital field technology:

“The suppliers to the construction industry should focus on delivering technology that really works out on the construction site,” and explains that they will put any new technology through stress testing in the field to ensure it can go into live projects.

—