Accelerating precast concrete manufacturing workflows with BIM and digital collaboration

VIDEO: Recording of our webinar about the Precast Concrete industry Thorsten Hertel (Trimble) and Eivind Berg (BuildingPoint Scandinavia).

Use the chapters to navigate.

The precast concrete industry is under increasing pressure to improve efficiency, reduce waste, and integrate digital workflows across design, manufacturing, and construction.

This article summarizes the take-aways from our webinar with Thorsten Hertel from Trimble. Watch the webinar to get the full picture to learn about the status of the industry and where it is heading!

Where are we today?

Building Information Modeling (BIM) has been central to the precast industry's development in the past couple of decades with the Norwegian precast industry standing out as an example of successful and early adoption of BIM, enabling better coordination, reducing errors, and streamlining processes.

However, many companies still face challenges in fully leveraging BIM for fabrication and production planning. Traditional workflows often result in disconnected data, inefficient communication between design and production teams, and missed opportunities for automation.

To address these issues, solutions such as Tekla Structures and Trimble Connect offer integrated workflows that connect detailing, production planning, and collaboration. The webinar, which you can watch on demand (and this article) explores how these technologies support more efficient precast manufacturing processes—along with ERP integration, and specialized extensions to Tekla and Trimble Connect.

Data-driven precast manufacturing with Tekla Structures

Tekla Structures provides a comprehensive BIM environment tailored for precast detailing, supporting production planning, and fabrication. By integrating all relevant data into a constructible model, it enables:

About BVBS

BVBS (Bundesvereinigung Bausoftware) is an industry-standard file format for exchanging rebar bending data between BIM software and fabrication machines.

By using BVBS, precast manufacturers can seamlessly transfer reinforcement data from Tekla Structures to automated rebar processing equipment, reducing manual input errors and improving production.

Precise detailing and model-based production planning – Reducing or even eliminating reliance on 2D drawings and ensuring production accuracy and use of the 3D model in all phases of the projects.

Seamless ERP and MES integration – Connecting Tekla models to enterprise resource planning (ERP), like solutions from SAP, Elematic and RIB SAA, and manufacturing execution systems (MES) for efficient production coordination.

Automated fabrication data exports – Supporting industry-standard file formats such as Unitechnik and PXML (for automation), BVBS (for reinforcement), and IFC4precast.

The transition from traditional drawing-based workflows to a fully digital model ensures that all stakeholders—from designers to factory operators—work with the same data, reducing miscommunication and rework.

Trimble Connect: A collaborative platform for precast workflows

FREE E-learning:

Trimble Connect Advanced Workflow Extensions

Check out our comprehensive e-learning course in Trimble Connect aimed at the advanced users! 20 lessons with demo file and practical exercises!

One of the biggest challenges in construction is keeping all stakeholders aligned throughout the project lifecycle. Trimble Connect provides a cloud-based platform that enables:

Real-time collaboration – Design, production, and site teams can access up-to-date BIM models, drawings, and fabrication data.

Integrated status tracking – Production progress can be visually monitored with Trimble Connect’s status sharing feature, ensuring that all parties have the latest information.

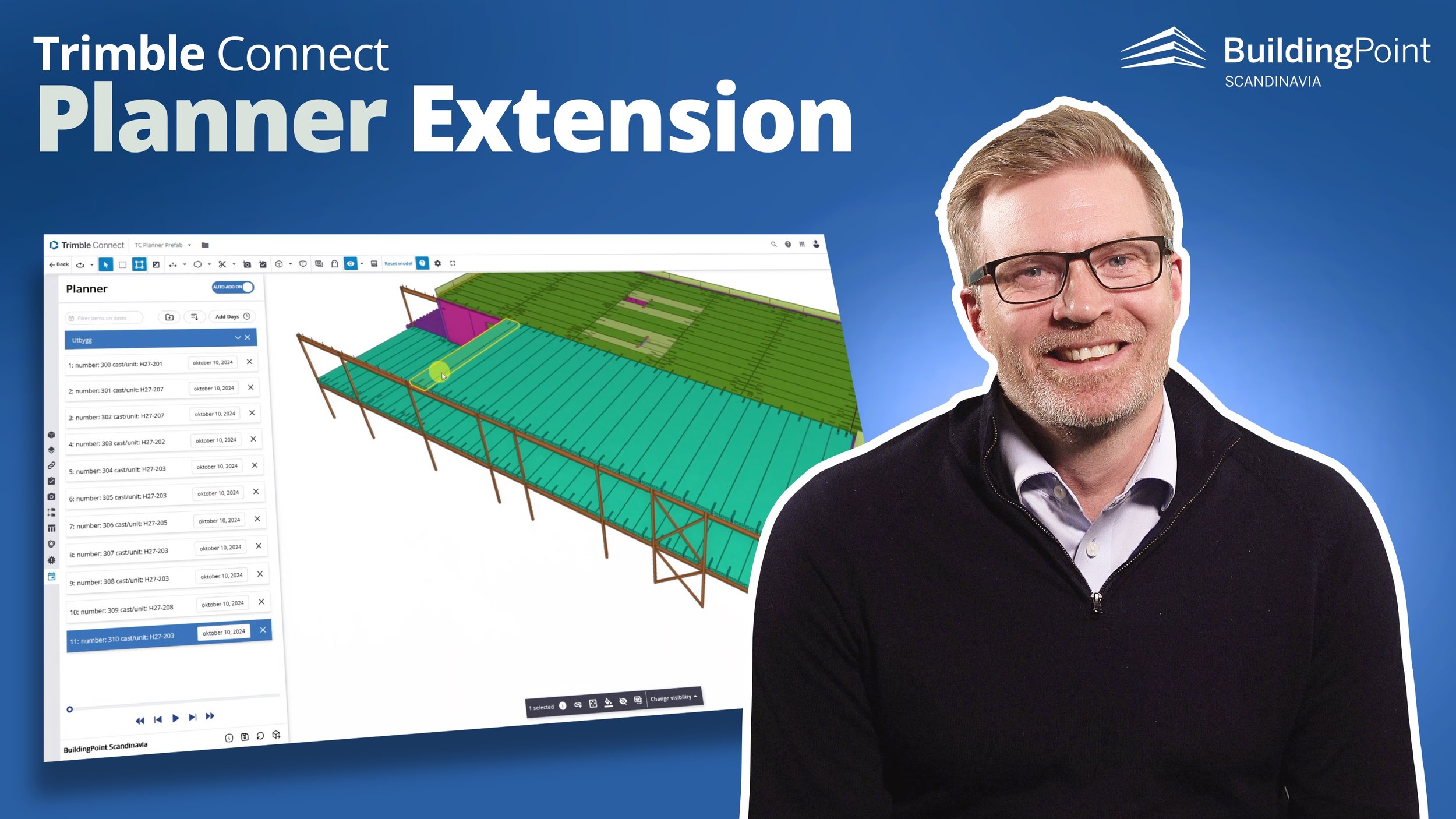

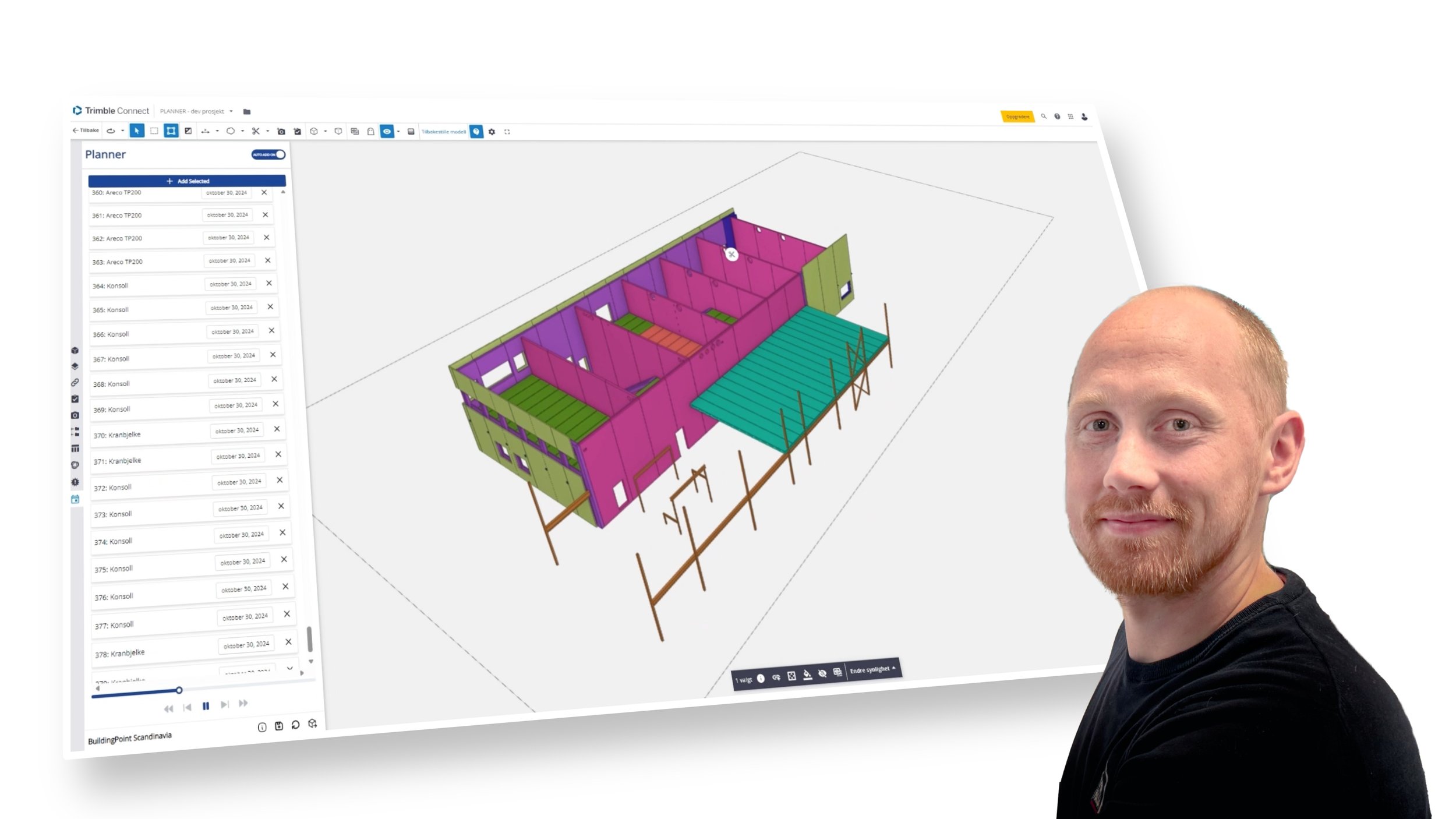

Advanced planning tools –Trimble Connect Planner Extension ca be used to schedule and visualize erection sequences to improve site logistics, and other tools!

Mixed reality applications – Augmented reality tools enable workers to overlay BIM data on-site, improving accuracy in installation and quality control.

By providing a central hub for information sharing, Trimble Connect reduces delays caused by outdated information and fragmented communication.

Enhancing precast workflows with Trimble Connect extensions

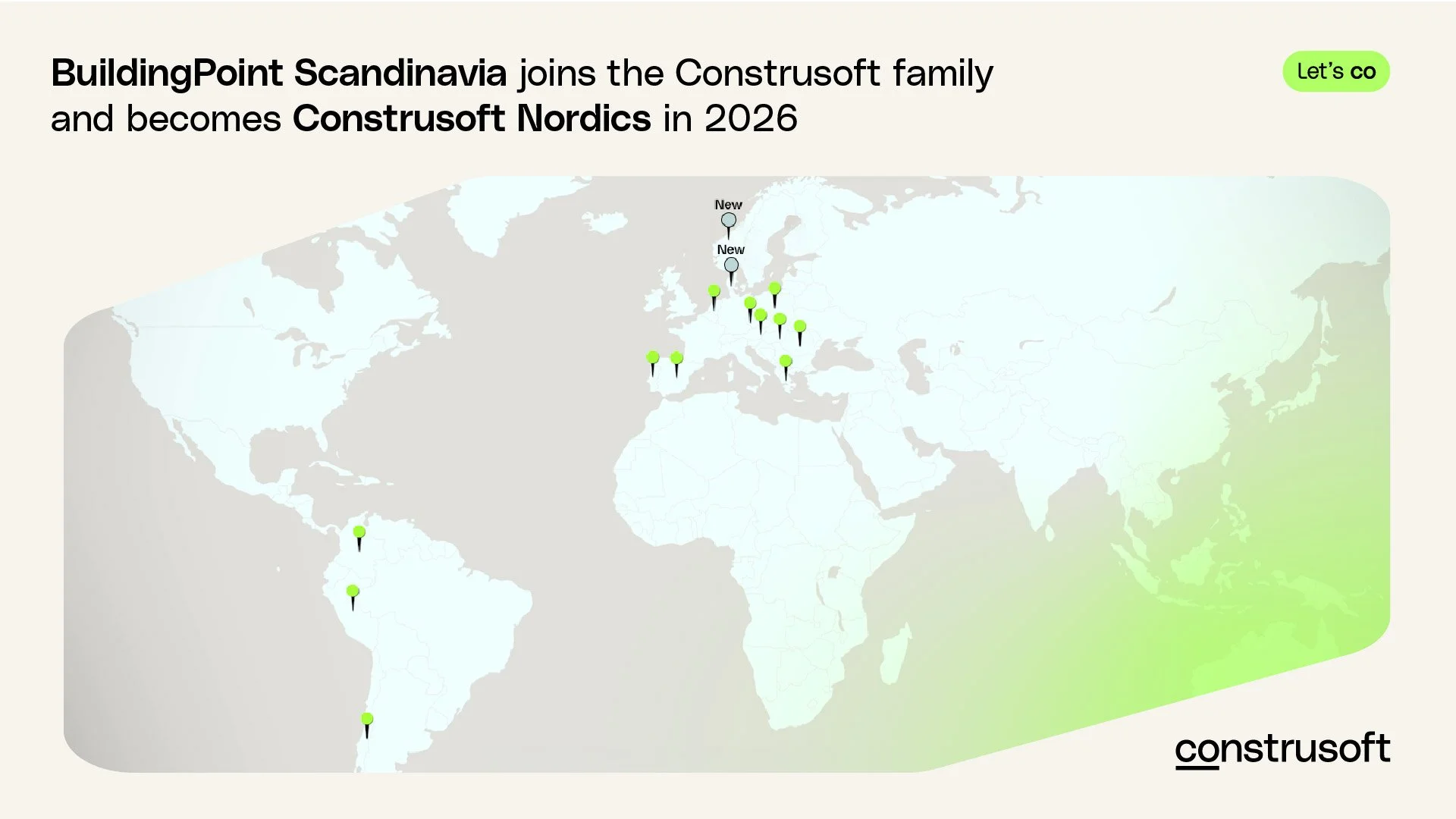

To further streamline precast production and planning, BuildingPoint Scandinavia has recently developed specialized extensions for Trimble Connect.

The Trimble Connect Rebar Labels extension simplifies reinforcement detailing by automatically generating clear, standardized rebar labels directly from the model. This reduces manual work, improves communication, and ensures greater accuracy on-site. It is currently in use in several infrastructure projects.

Read more about how Skanska uses the Trimble Connect Rebar Labels extension.

.

.

The Trimble Connect Planner extension enhances project logistics by enabling visual scheduling of erection sequences. Users can plan, adjust, and track installation progress in real-time, ensuring better coordination between the factory and the construction site.

These extensions add useful functionality to Trimble Connect, helping precast manufacturers work more efficiently with improved clarity and control over production and assembly.

Automated and connected fabrication

Automation is a key driver of efficiency in precast manufacturing. However, for companies to fully benefit from automated workflows, production data must be standardized and seamlessly integrated into factory systems.

IFC4precast is emerging as a solution to unify production data, moving beyond traditional file-based exports (such as Unitechnik and BVBS) to a fully interoperable model-based approach.

Benefits of IFC4precast include:

Flexible production planning – A single data format that allows manufacturers to shift production between different factories without manual reconfiguration.

Rich, structured data – The ability to store and transmit full 3D geometry, reinforcement details, and metadata within a single IFC model.

Future-proof integration – Designed as an industry-wide standard to ensure compatibility across different software and hardware platforms.

For companies investing in automation, adopting open standards like IFC4precast can help future-proof their workflows and enable smoother digital transformation.

.

.

Conclusion: Leveraging technology for smarter precast workflows

The transition to fully digital precast workflows is no longer just an option—it’s becoming a necessity for companies looking to remain competitive. By integrating BIM, cloud collaboration, and automation, manufacturers can achieve greater accuracy, efficiency, and scalability in their operations.

Tools like Tekla Structures and Trimble Connect, along with specialized extensions developed by BuildingPoint Scandinavia and others, has a historical track record of providing the foundation for this transformation. These solutions will continue to enable data-driven decision-making, seamless collaboration, and automated production processes, helping companies deliver high-quality precast elements efficiently and sustainably.

Overhalla Betongbygg

Learn about how Overhalla Betongbygg’s projects went from hundreds to thousands of prefabricated concrete elements, and how the Trimble Connect Planner Extension helps them more work efficiently.

OTHER ARTICLES