Experiences from NYMO:

Using AR in fabrication of offshore structures

By Tomas Jakobsen, BuildingPoint Scandinavia

This article is also available in Norwegian (PDF),

click here to download

NYMO has been digitalizing its work processes in recent years to secure high-quality offshore deliveries.

Recently, the company introduced AR technology, which has already proven valuable for detecting deviations, ensuring assembly accuracy, and improving efficiency in the field.

From drawings to AR

Quality control in offshore projects has traditionally been paper-based, with large drawing binders and manual checks in the field — a process that carries risk, especially when engineering and fabrication run in parallel.

NYMO has recently introduced Trimble Connect and Trimble SiteVision (formerly Trimble Connect AR) as tools for visual inspection and verification directly against the 3D model.

According to CAD Administrator Kjetil Kile, the motivation for testing AR was initially practical: to detect errors earlier and reduce the number of deviations found during final inspection. Today, the technology is actively used in several parts of the workflow.

«We’ve gone from using only paper and pencil in the field to also having the model with us on the iPad. That means we can identify errors earlier and document them directly in the model,» says Kile.

IMAGE: Kjetil Kile, CAD Administrator at NYMO.

“

We’ve gone from using only paper and pencil in the field to also having the model with us on the iPad. That means we can identify errors earlier and document them directly in the model.

- Kjetil Kile, CAD Administrator, NYMO

Use cases and experiences

Users report clear benefits in daily work:

Better visualization: Components can be viewed in physical context, with a clear overview of progress and plans.

Faster error detection: Missing items, misplacements, and deviations are caught earlier in the process.

Simpler communication: Findings and clarifications are documented and shared directly in the model.

A concrete example is work with pipe supports, where assembly and welding follow-up used to be cumbersome and required extensive coordination. With the AR model available in the field, field engineers can quickly verify status and document any deviations directly in the model.

«We have several cases where we detected steel components installed incorrectly at an early stage. The deviation would likely have been harder to catch using only drawings; the visibility provided by the 3D model and AR saved both time and rework,» says Kile.

VIDEO: Trimble SiteVision in use at NYMO’s fabrication site in Grimstad.

“

Roll stoppers were modeled according to the drawings, but in reality they extended far beyond the vessel side.

Trimble SiteVision clearly showed the deviation that could have caused a serious time delay for sea transport and lifting.

- Odin-Eliott Odinson, Dimensional Control Lead, NYMO

Project examples

In addition to general error detection in the field, AR use has proven especially valuable in understanding the interaction between transport equipment and the project delivery.

Preparing for shipping

In a project for Aker BP, where NYMO was about to place a walkway bridge on a barge for transport to the field, Trimble SiteVision was used to check placement of roll stoppers and mooring equipment against the model. Even though the 3D model and barge drawings were used during design and interface checks, not all details matched the actual barge — something the team discovered during inspection in the Netherlands.

«Roll stoppers were modeled according to the drawings, but in reality they extended far beyond the vessel side. SiteVision clearly showed the deviation that could have caused a serious time delay for sea transport and lifting,» says Odin-Eliott Odinson, Dimensional Control Lead at NYMO.

With AR, the team was able to detect and document the deviation before the barge was sent to Norway for the load-out of the walkway bridge. During the same inspection, they also discovered that bollards and chocks had been moved compared to the model — a change that could have blocked the bridge’s driving path during loading.

«Because we knew this in advance, we could allocate time and crew to move the equipment before the barge arrived. We avoided delays, rework, and stress in a critical phase,» says Odinson.

«That single discovery alone was enough to justify the entire trip...»

“

Because we knew this in advance, we could allocate time and crew to move the equipment before the barge arrived. We avoided delays, rework, and stress in a critical phase. That single discovery alone was enough to justify the entire trip.

- Odin-Eliott Odinson, Dimensional Control Lead, NYMO

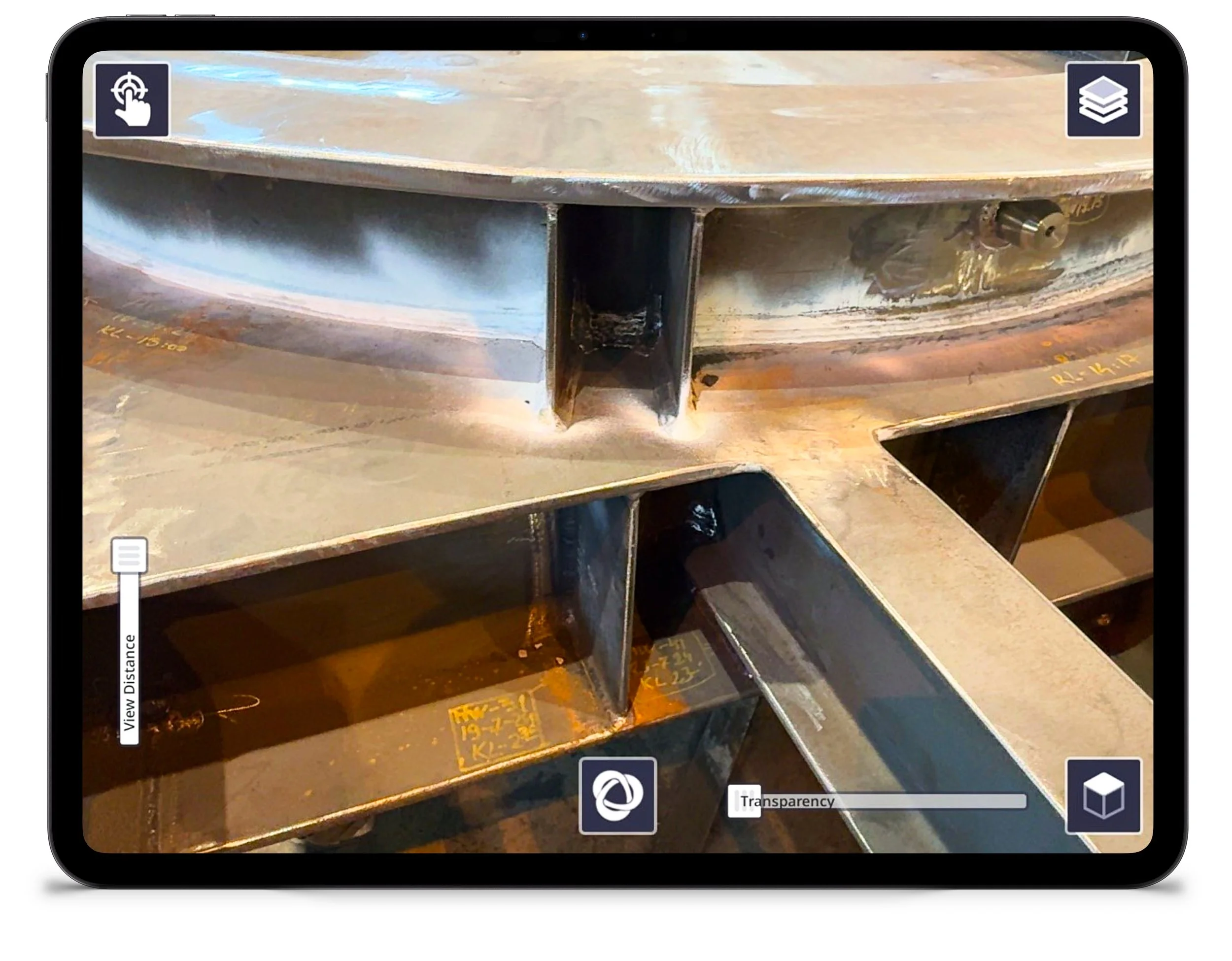

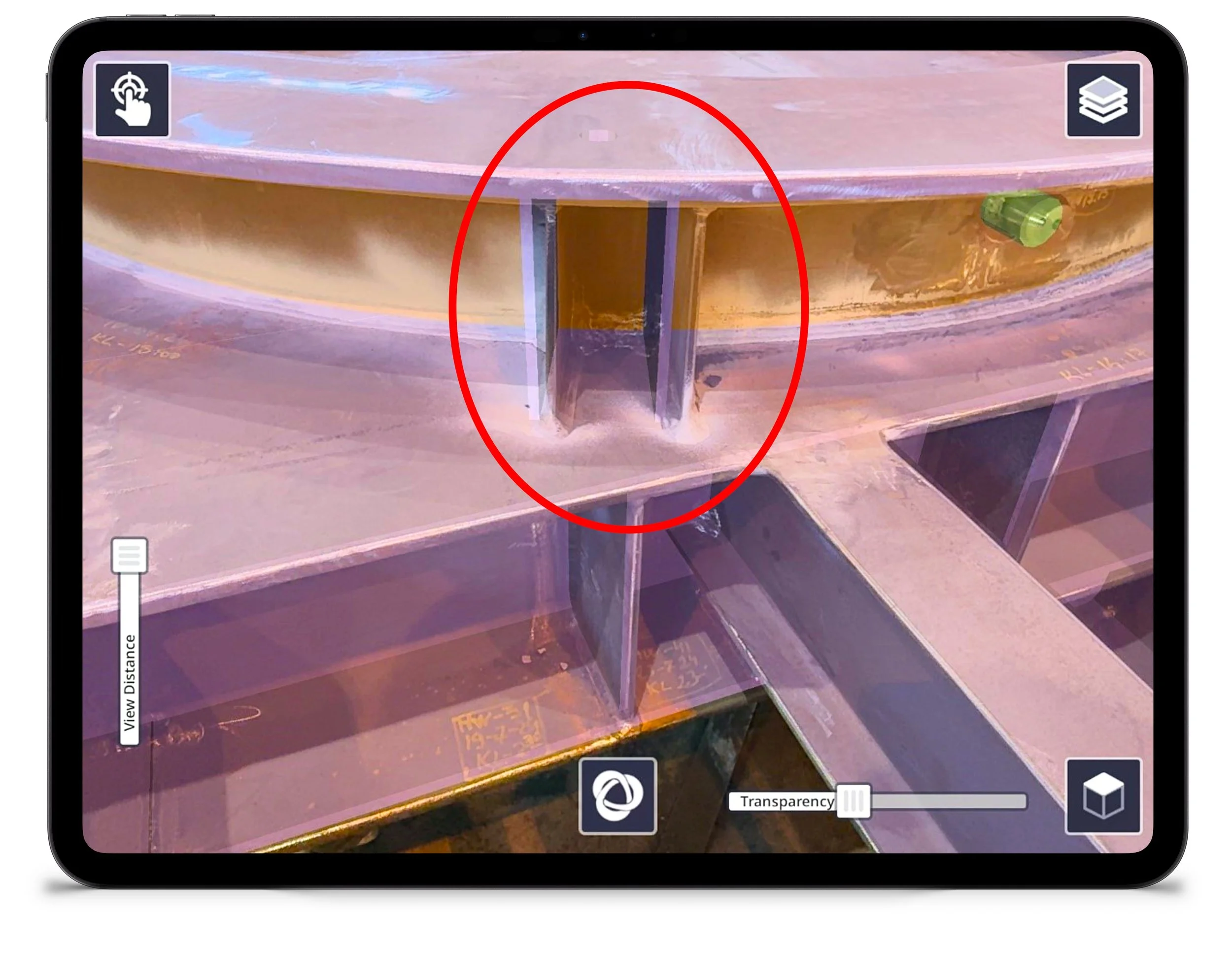

Fabrication

Another typical example comes from production, where two stiffeners were mounted and welded in the wrong position — just a few centimeters off, but enough to cause downstream problems.

This would not have been discovered until the next assembly stage, potentially leading to rework and loss of time. Instead, the error was caught with Trimble SiteVision before welding.

«We could make the adjustment before production continued. The field engineer who found the error believes that this type of mistake is hard to spot by eye, but becomes obvious when the model is projected directly onto the structure,» says Kjetil Kile, noting that these are exactly the kinds of deviations they expect to catch much earlier going forward.

Both examples illustrate how AR does not necessarily replace traditional measurement methods, but provides an immediate visual aid that is quick to use — and low-threshold enough for multiple disciplines to adopt.

«Once QR codes are set out, anyone can bring up the model and do a simple visual check. It requires little training and gives immediate answers,» says Odinson.

“

The field engineer who found the error believes that this type of mistake is hard to spot by eye, but becomes obvious when the model is projected directly onto the structure.

- Kjetil Kile, CAD Administrator, NYMO

Time savings and user feedback

In an internal survey, more than half of users said they use Trimble Connect and/or Trimble SiteVision daily, and that the tools noticeably increase efficiency. Estimated time savings range from 20 to 50 percent, depending on the task and user experience.

«It’s important to be realistic. Not all users achieve the same results, and some of the gains come in the form of freed-up capacity — not necessarily shorter execution time. But it does contribute to better flow and fewer interruptions in the field,» says Kile.

The use of AR has also increased awareness around data quality and digital production. When more people in the field work directly in the model, the requirements for accuracy and structure in engineering deliverables also increase.

IMAGE: Trimble SiteVision helps identify two beams that have not been installed when the 3D model is overlaid on the physical structure. (Image courtesy of NYMO)

Standardizing processes

Even though the tools are now widely used, they are not yet part of NYMO’s formal project standards. How findings and comments are documented in the model — for example, using views, color coding, or text markup — still varies between projects and users.

«We are still in the process of establishing a common practice. The next step is to define how we use the tools systematically and make it part of NYMO’s standard execution model,» says Kile, adding that the organization is good at implementing this kind of continuous improvement when new technology can build on already established processes.

ARTICLE: Read more about how NYMO uses Tekla in fabrication of offshore structures.

IMAGE: Kjetil Kile, NYMO (left), Anders Sand-Larsson, BuildingPoint Scandinavia / EDRMedeso (center) and Odin-Eliott Odinson, NYMO, discussing the workflow and how AR technology can be used.

Next step: More data in the model

One topic that came in the wake of AR use is the need for more fabrication-relevant information directly in the model — especially welding information. Today, welds are mainly documented on drawings, but there are now considerations to model them directly in Tekla to simplify follow-up and information flow in the field.

Another possibility is to make models available on screens in the workshops, so production workers can access necessary information without relying on drawings or CAD users.

Want to get started with AR?

Check out Trimble SiteVision, or reach out to our team

Summary

The use of AR at NYMO has already led to better quality control and more efficient work in the field. Errors are caught earlier, and collaboration between fabrication, engineering, field engineers, QC, and MC (Quality Control, and Mechanical Completion) is strengthened.

At the same time, work is ongoing to standardize use so that the tools can be applied consistently across disciplines and projects.

«This has given us a new way of working. Now it’s about making it a natural part of the process — not just an add-on for the most technically inclined,» concludes Kile.

About Nymo

AS Nymo is a full-service engineering, procurement and construction company within the oil & gas and process industry.

Nymo offers total solutions to customers and has earned confidence for versatility, reliability, quality service, timely delivery, good project management and commitment to HSE excellence…