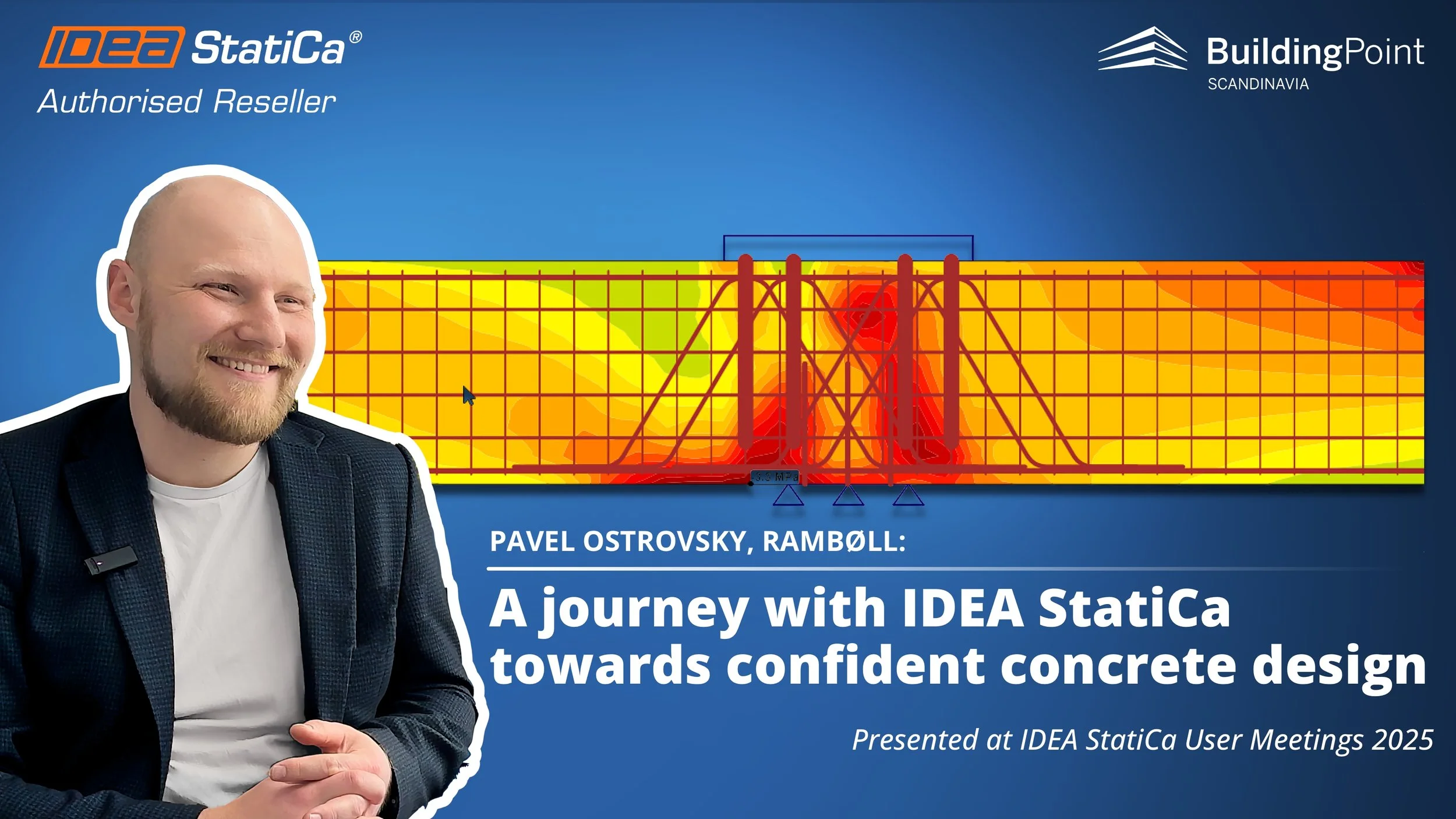

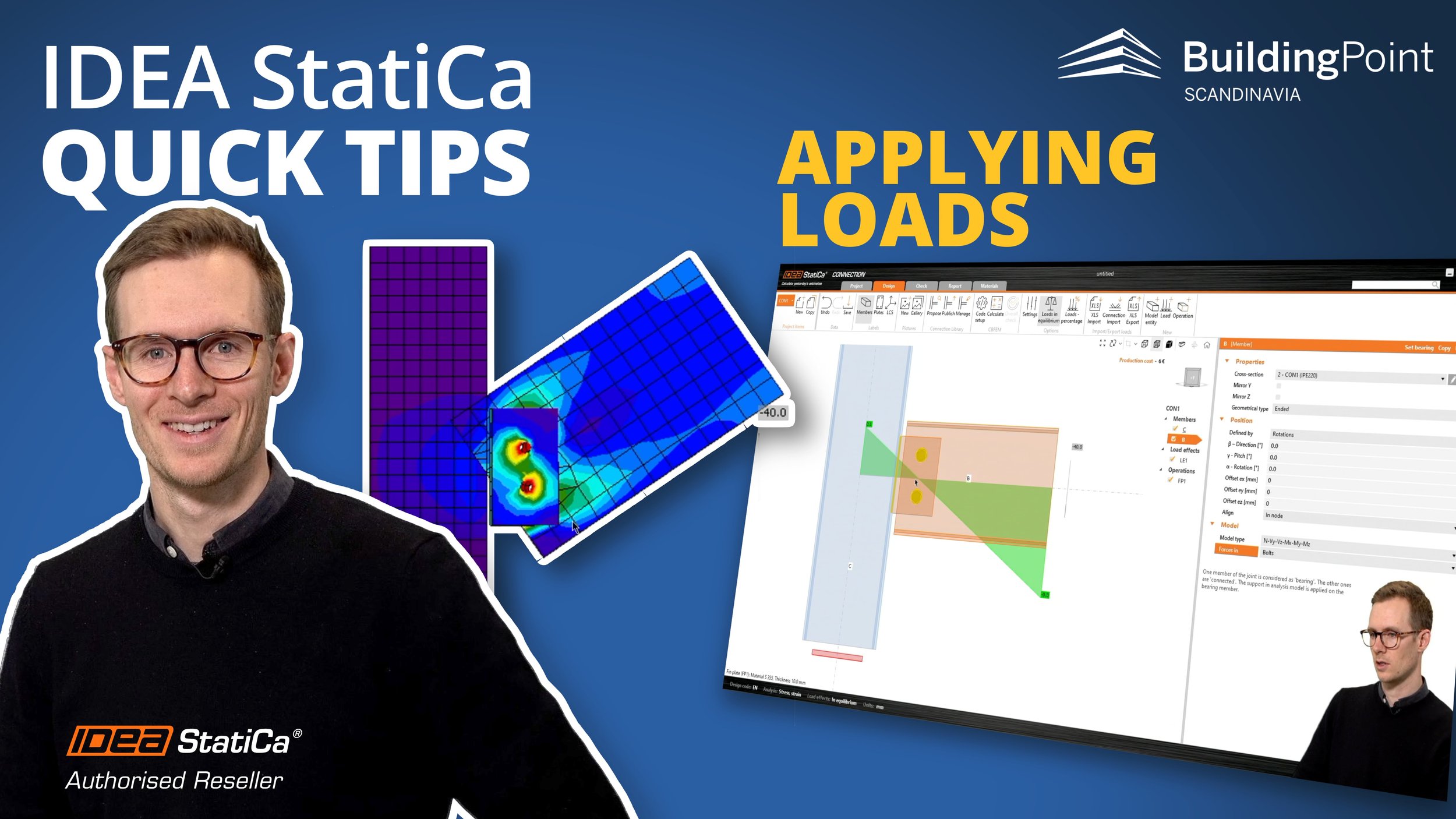

One user’s journey with IDEA StatiCa: From promising but limited beginnings to confident concrete design

VIDEO: Recorded presentation from the 2025 IDEA StatiCa User Meeting in Finland. Pavel Ostrovsky, Design Manager at Rambøll, shared how his work with reinforced concrete design has evolved alongside IDEA StatiCa.

All images and video courtesy of Rambøll.

At the 2025 IDEA StatiCa User Meeting in Finland, Pavel Ostrovsky, Design Manager at Rambøll, shared how his work with reinforced concrete design has evolved alongside IDEA StatiCa. What began in 2019 with limitations and frustrations has grown into a powerful toolset now applied on industrial projects across Europe and the Americas.

Watch the recorded presentation to get all the details along with project examples, verification examples and perspectives about how IDEA StatiCa helps accelerate engineering workflows!

Early encounters with IDEA StatiCa

In 2019, Pavel encountered a column design with anchor plates on three sides that pushed conventional tools to their limits. The promise of IDEA StatiCa’s “Detail” module seemed like the solution — a user-friendly environment for parametric concrete design.

“I was thrilled. It looked like a true 3D modeling environment,” Pavel recalls. “But after hours of trying to define loads on that third side, reality hit — it was actually a 2.5D environment,” reminding us that this was back in 2019!

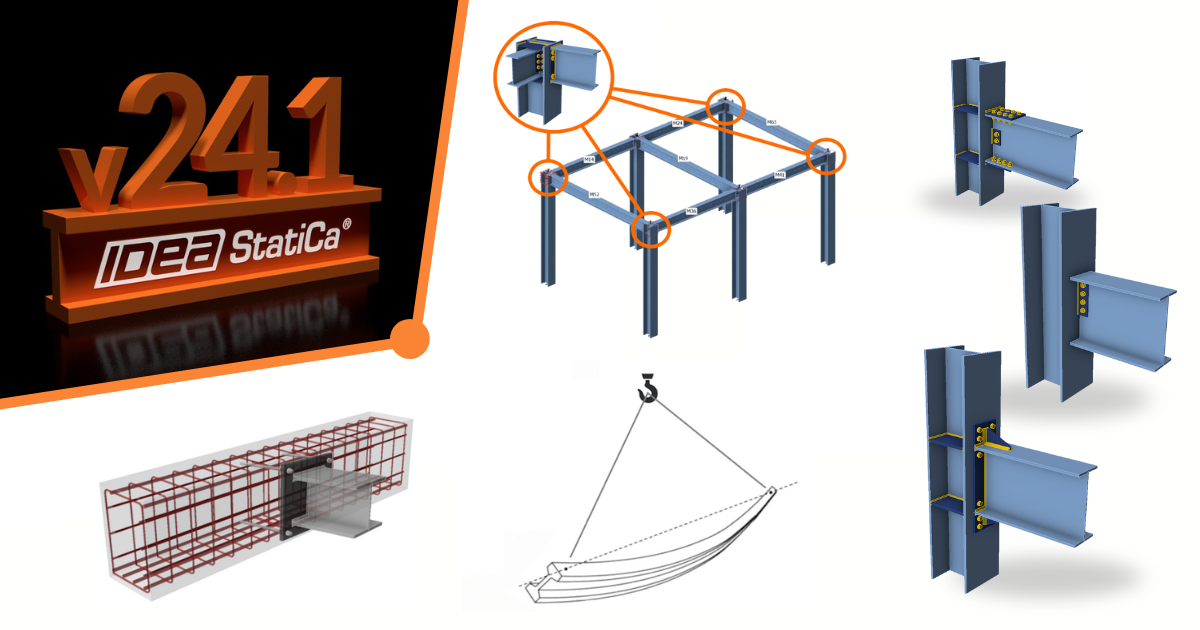

While this specific challenge had to wait, the software showed strong potential, in Pavel's opinion, for tackling other complex situations in reinforced concrete. Over the following years, IDEA StatiCa Detail matured into a true 3D environment, gradually addressing the needs of engineers designing non-standard connections and discontinuity regions.

The challenge of D-regions

TABLE: Comparison of options for structural analysis of concrete D-regions

Concrete design often hinges on how to treat discontinuity regions (D-regions) — zones around openings, supports, or concentrated loads where linear beam theory no longer applies.

These areas demand careful engineering judgment. Traditional approaches, whether through handbooks, strut-and-tie models, or nonlinear FEM tools, all have trade-offs between accuracy, efficiency, and practicality.

According to Pavel, this is where IDEA StatiCa fills an important gap:

“IDEA StatiCa strikes an excellent balance between accuracy and usability. It implements nonlinear material models and reinforcement behavior without requiring the user to specify dozens of parameters.”

Comparing with nonlinear FEM Tools

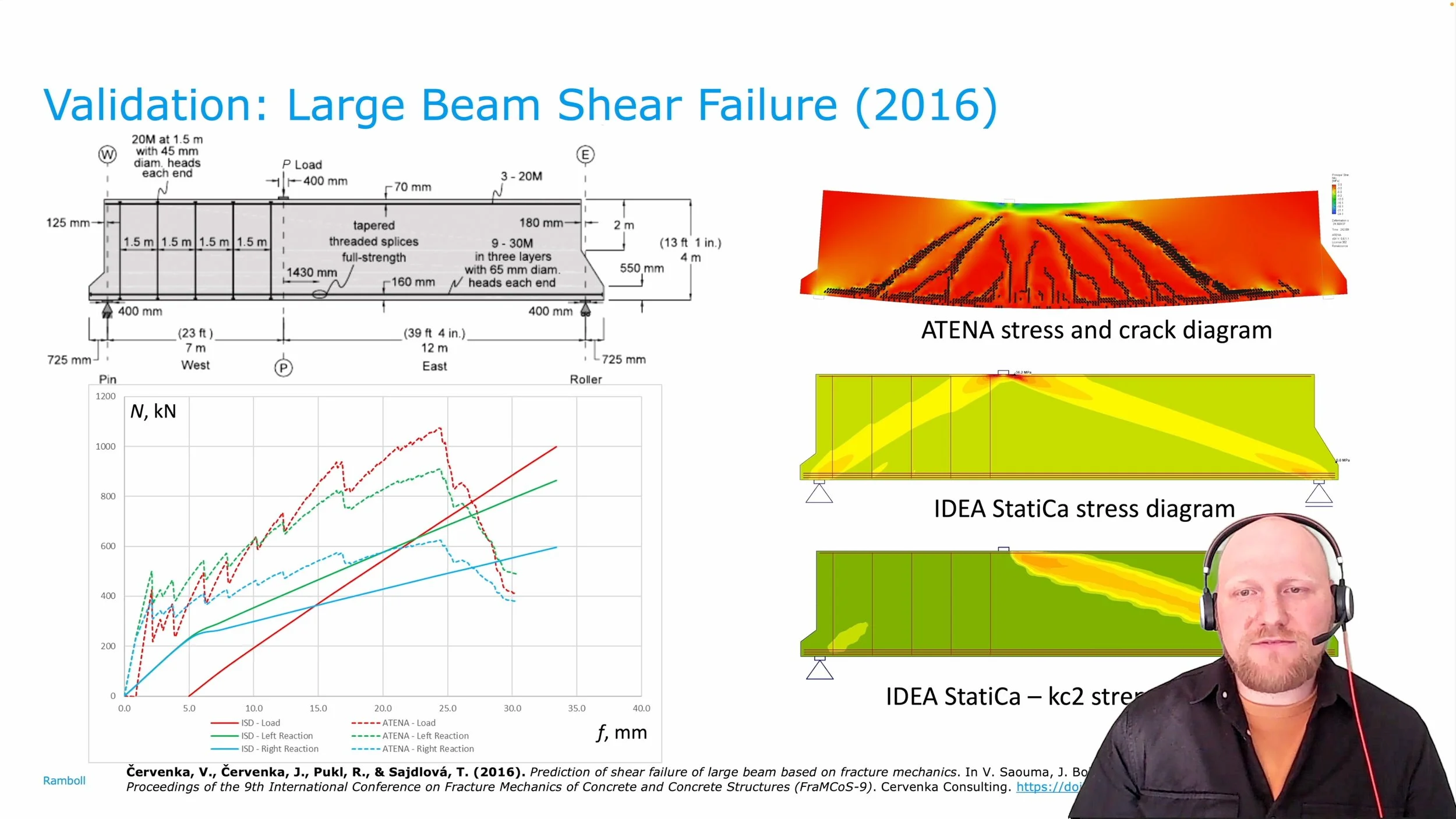

IMAGE: Screenshot from the video (time: 06:12) where the Leonhardt’s Beam Test is discussed comparing results from tests and IDEA StatiCa along with another analysis software.

Years of experience with advanced FEM programs highlighted just how demanding those methods can be. Defining dozens of parameters, producing reliable meshes, and learning complex interfaces required significant time investments — often more than project timelines could allow.

“Creating proper finite element meshes for complex geometries requires serious expertise,” Pavel explains.

“With other softwares, it may take about six months to get comfortable enough to produce reliable results. That’s just not practical in a commercial environment.”

IMAGE: Screenshot from the video (time: 07:00) where the Large Beam Shear Failure Test is discussed comparing results from tests and IDEA StatiCa along with another analysis software.

IDEA StatiCa reduces that burden, automating the most intricate aspects of nonlinear concrete analysis.

Validation against experimental tests has shown it provides reliable predictions of capacity and failure modes, while leaning slightly conservative in deflections — an acceptable and even beneficial trait in design practice.

“

IDEA StatiCa strikes an excellent balance between accuracy and usability. It implements nonlinear material models and proper reinforcement behavior without requiring the user to specify dozens of parameters.

- Pavel Ostrovsky, Rambøll

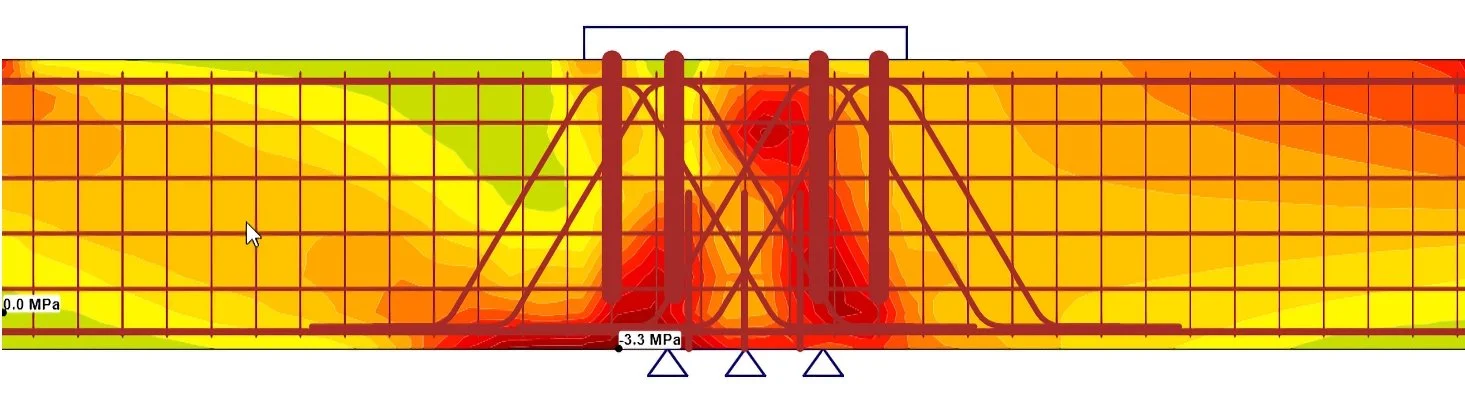

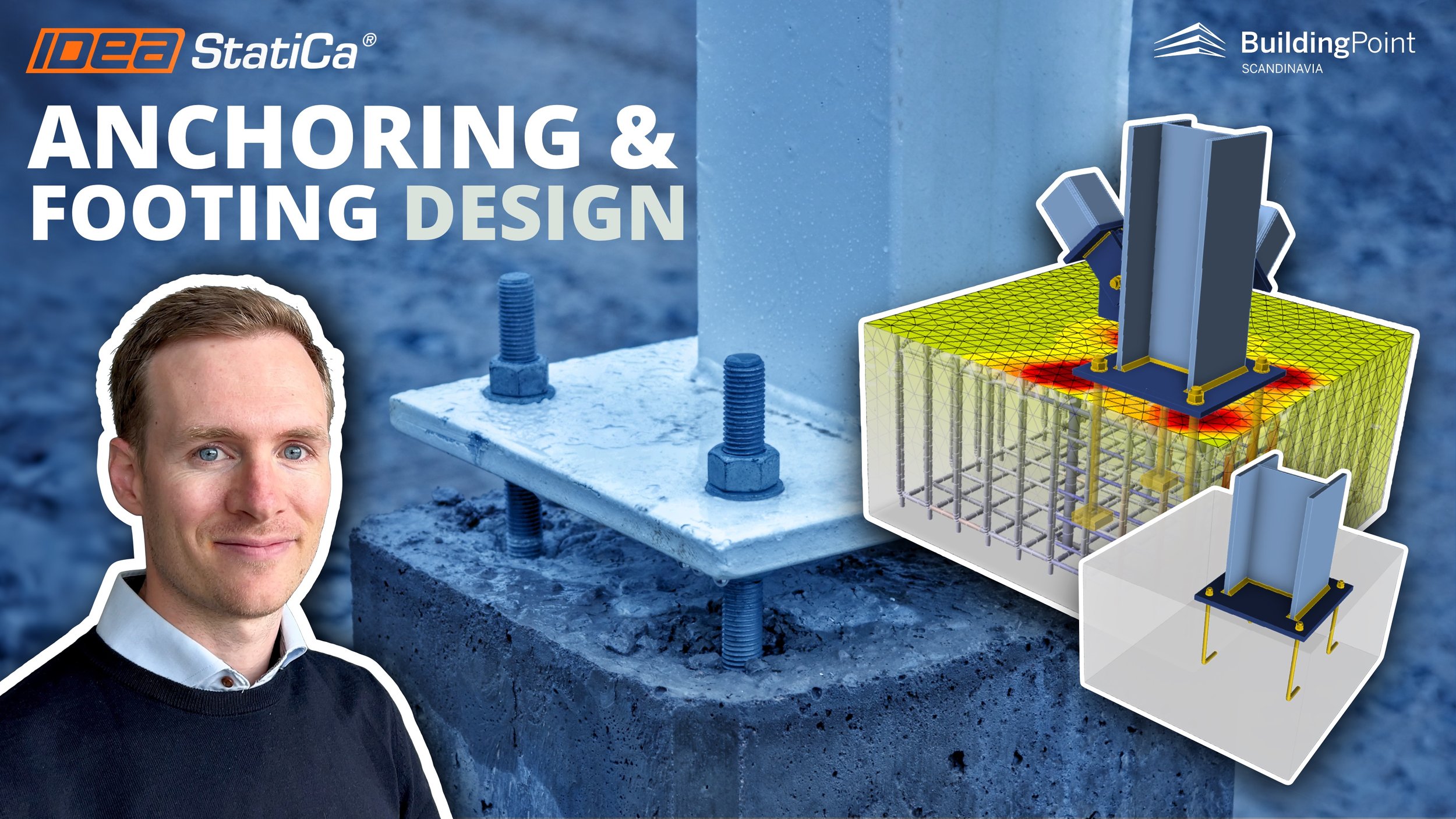

IMAGE: Example of excessively reinforced concrete. IDEA StatiCa helped eliminate the complicated layouts

Application examples from projects

Case 1: Complex anchoring

One recurring challenge in reinforced concrete design is anchor detailing. In one project, proprietary anchor design software suggested reinforcement layouts that would have required sixty-four separate bars packed tightly around a group of eight anchor bolts.

Not only was this excessive, it created serious constructability issues — placing concrete properly in such a congested area would have been nearly impossible.

“We redesigned the supplementary reinforcement,” says Pavel. “Our analysis showed that U-bars plus trough-shaped rebars provided adequate strength. We eliminated the complicated layouts, but kept some bent rebars for extra safety.”

ARTICLE:

Rambøll and The Twist

Read the story about how Rambøll solved design challenges at Kistefos museum — “The Twist”

Case 2: Anchoring in seismic zones

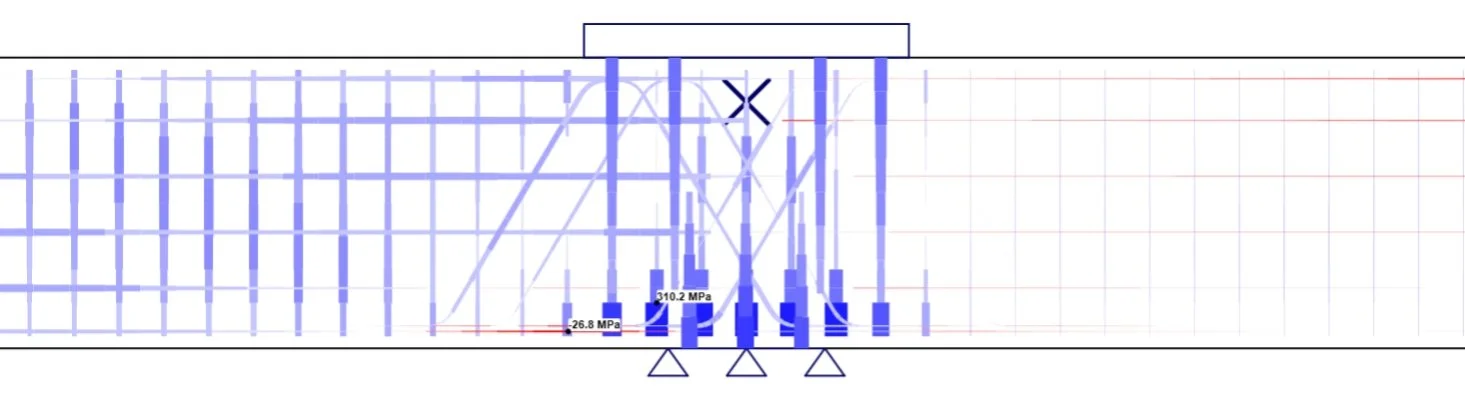

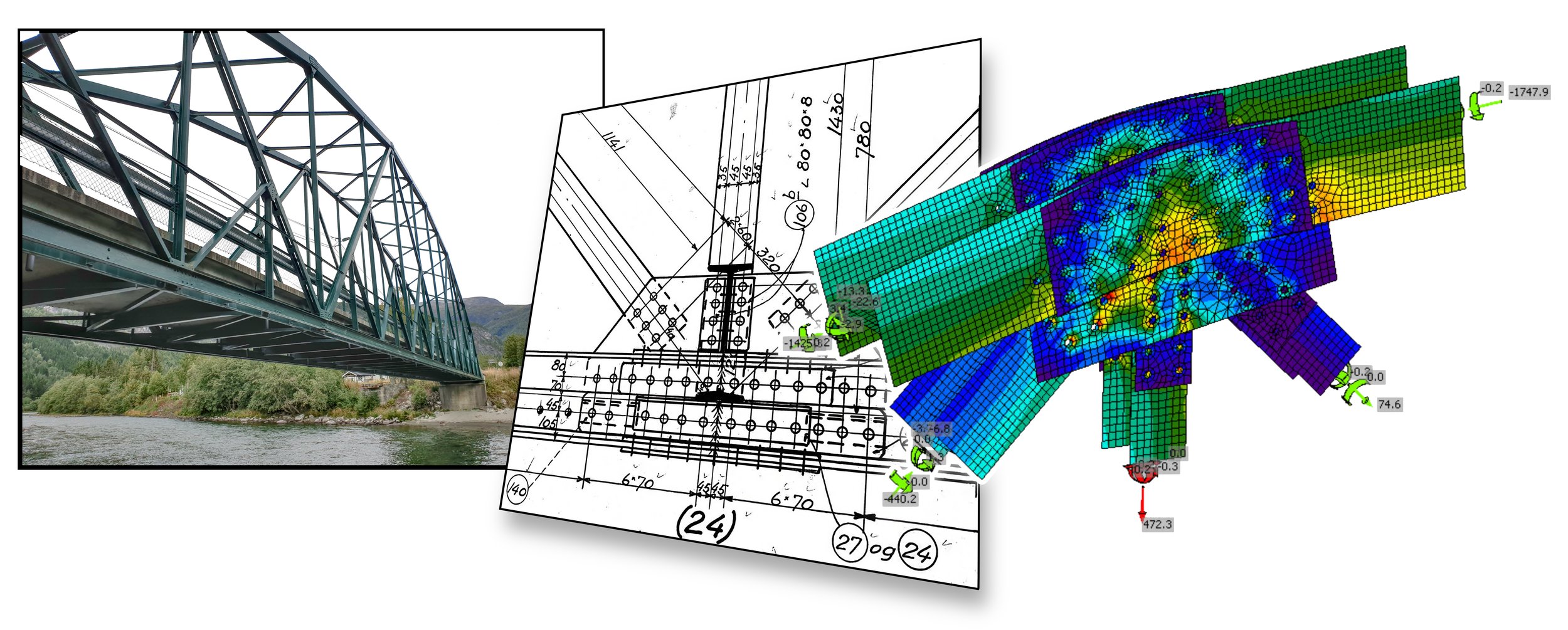

IMAGE: An perfect example from a South American project in a high seismicity area. These are braced column connections where all bolts experience tension - a challenging scenario for anchor design.

Another case involved projects in seismic regions, where high tension forces in braced column connections pushed standard detailing rules beyond their limits.

By modeling alternative reinforcement strategies in IDEA StatiCa, uplift forces could be distributed more effectively through the pile caps, ensuring both structural safety and constructability.

“These were extreme forces,” Pavel notes. “Standard handbook reinforcement became impractical, so we developed much more rational layouts that reflected the structure’s true behavior.”

SLIDESHOW: The end design had a much more rational reinforcement layouts. The IDEA StatiCa model served double duty - verifying both pile cap and anchor bolt design in one go.

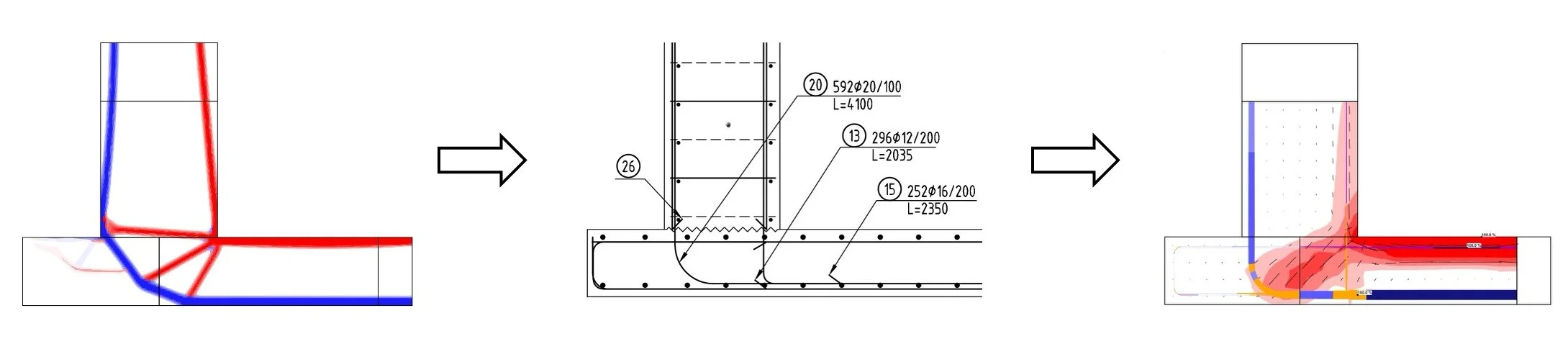

Case 3: Beams with openings

IMAGE: Beams with openings – even though there are multiple guidances how to make detailing around opening, it is still difficult to quantify the design.

Openings in beams present another familiar difficulty. While codes and guidelines offer general advice, quantifying their real impact can be tricky. Using IDEA StatiCa’s topology optimization, stress flows could be visualized and openings placed where they disrupted the structure the least.

“First, topology optimization shows stress flow patterns,” Pavel explains. "This helps us position openings where they cause least disruption. Second, we calculate and compare utilization ratios to quantitatively verify that our proposed openings are safe."

Case 4: High-rise core wall

A final example came from the design of a 67-meter-high core wall, where hundreds of reinforcement objects had to be modeled. In 2019, such a model was barely manageable, with long calculation times and heavy manual input. By 2025, IDEA StatiCa could process the same structure in minutes rather than hours, with smoother handling of geometry and loads.

“I used to wait ninety seconds just to zoom in or out,” says Pavel. “Now, navigation is instant, and calculation time is down from two hours to just seven minutes.”

IMAGE: 67 meters tall core wall — Pushing the limits of IDEA StatiCa back in 2019…

“

They’ve stripped away complexity to let us focus on actual engineering.

Just as Connection transformed steel design, Detail is changing how we approach concrete D-regions.

- Pavel Ostrovsky, Rambøll

Limitations and ongoing development

While IDEA StatiCa has made major strides, no software is without its limitations. Certain workflows still leave room for refinement, and not every feature an engineer might wish for is yet available.

What stands out, however, is the steady pace of development. Many of the obstacles that once felt critical in 2019 have now been resolved, and the software continues to evolve in ways that broaden its scope of application, according to Pavel.

A shift in concrete design

From its early role as a promising but restricted tool, IDEA StatiCa has grown into a practical solution for reinforced concrete D-regions. By removing the complexity of traditional nonlinear FEM, it allows engineers to focus on engineering judgment and constructible design.

As Pavel sums up: “They’ve stripped away complexity to let us focus on actual engineering. Just as IDEA StatiCa Connection transformed steel design, IDEA StatiCa Detail is now changing how we approach concrete D-regions.”

For Pavel and his colleagues in Rambøll, this shift has meant it's possible to move from frustrating workarounds to efficient, verifiable solutions that hold up in real-world projects.

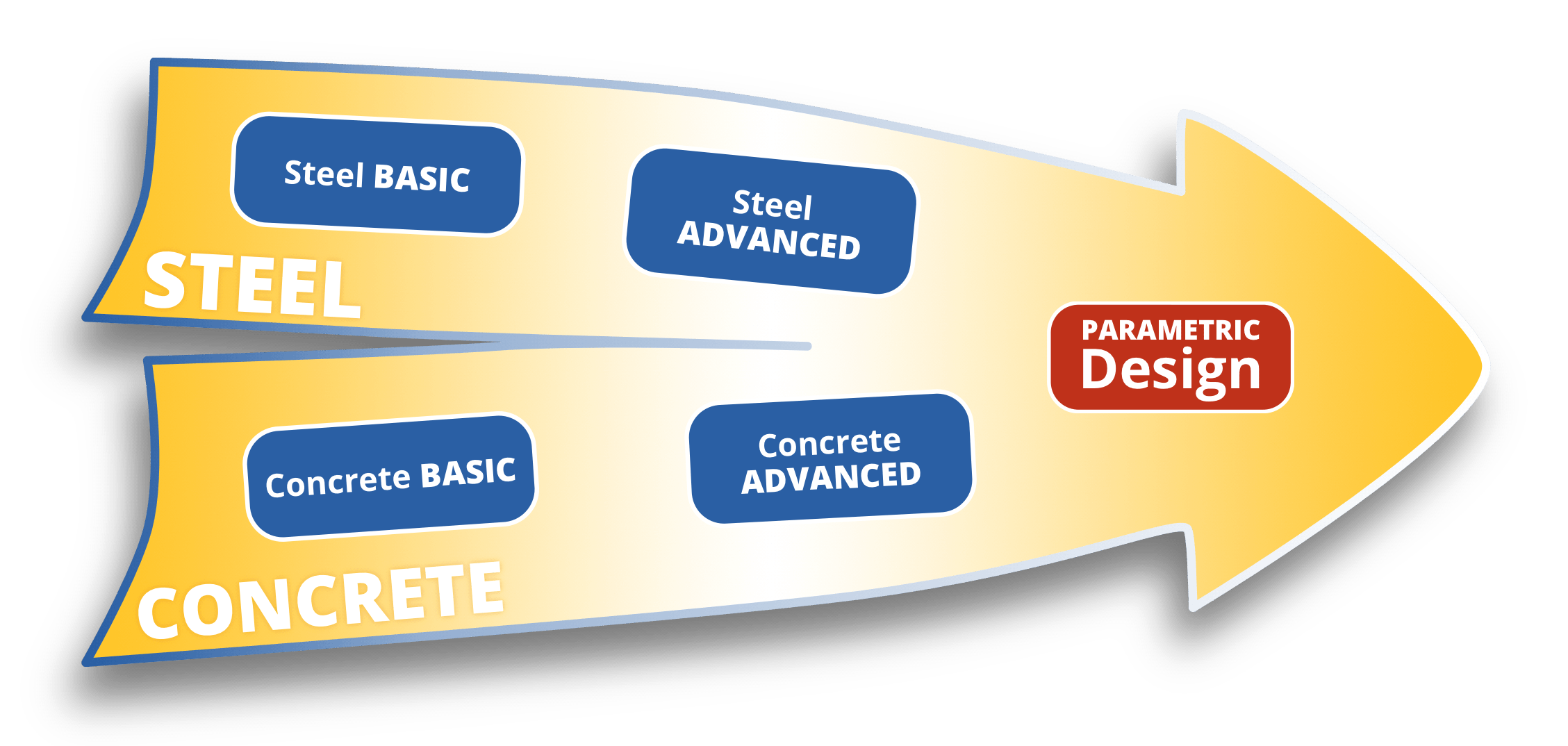

Training!

Check out our training programs for STEEL and CONCRETE, and even more advanced topics, like Parametric Design with IDEA StatiCa…

OTHER ARTICLES