Thank you for attending our Precast Concrete afternoon event in Denmark!

We’d like to say THANK YOU to everyone who joined us in Herning for the Industry Afternoon Workshop – Digital Workflows in Precast Concrete!

The event brought together engineers, designers, and production specialists from the Danish precast community for a focused afternoon of knowledge sharing and discussion.

The feedback was very positive—our post-event survey resulted in an average rating of 4.6 out of 5 stars, reflecting strong engagement and valuable discussions throughout the session, we hope!

Special thanks to the speakers!

A special thanks goes to our guest speakers:

Kim Schmeltz, Head of Development at Spæncom, Niels Christian Sønnichsen, Head of Design at Industri Beton, and Alexis Borderon at Concribe!

Did you miss the event?

…here’s what we covered!

From fragmented 2D processes to 3D model-based collaboration

Background — the challenges!

Many precast teams still work with a mix of 2D drawings, spreadsheets, and manual coordination between departments. While familiar, these disconnected processes often lead to errors, rework, and delays—especially as project complexity and client expectations increase.

Moving to 3D and model-based workflows helps connect planning, design, production, and site teams around accurate, up-to-date information. It’s not just about drawing in 3D—it’s about enabling better decision-making and more predictable outcomes.

Some companies made this transition over a decade ago. By replacing 2D CAD with Tekla Structures, customers report having reduced detailing errors by 80%, shortened project timelines by several weeks, and improved collaboration across teams.

Design changes that once caused downstream problems can now be handled directly in the model—keeping production aligned and reducing rework on site.

Experience shows that a phased, practical transition is possible—and highly beneficial. This workshop was designed to help attendees understand what that change can look like in your own environment!

(Continued below…)

WEBINAR: Accelerating Precast Concrete Manufacturing

Watch this comprehensive presentation by Thorsten Hertel about the state of things related to digital solutions for the Precast Industry!

ARTICLE:

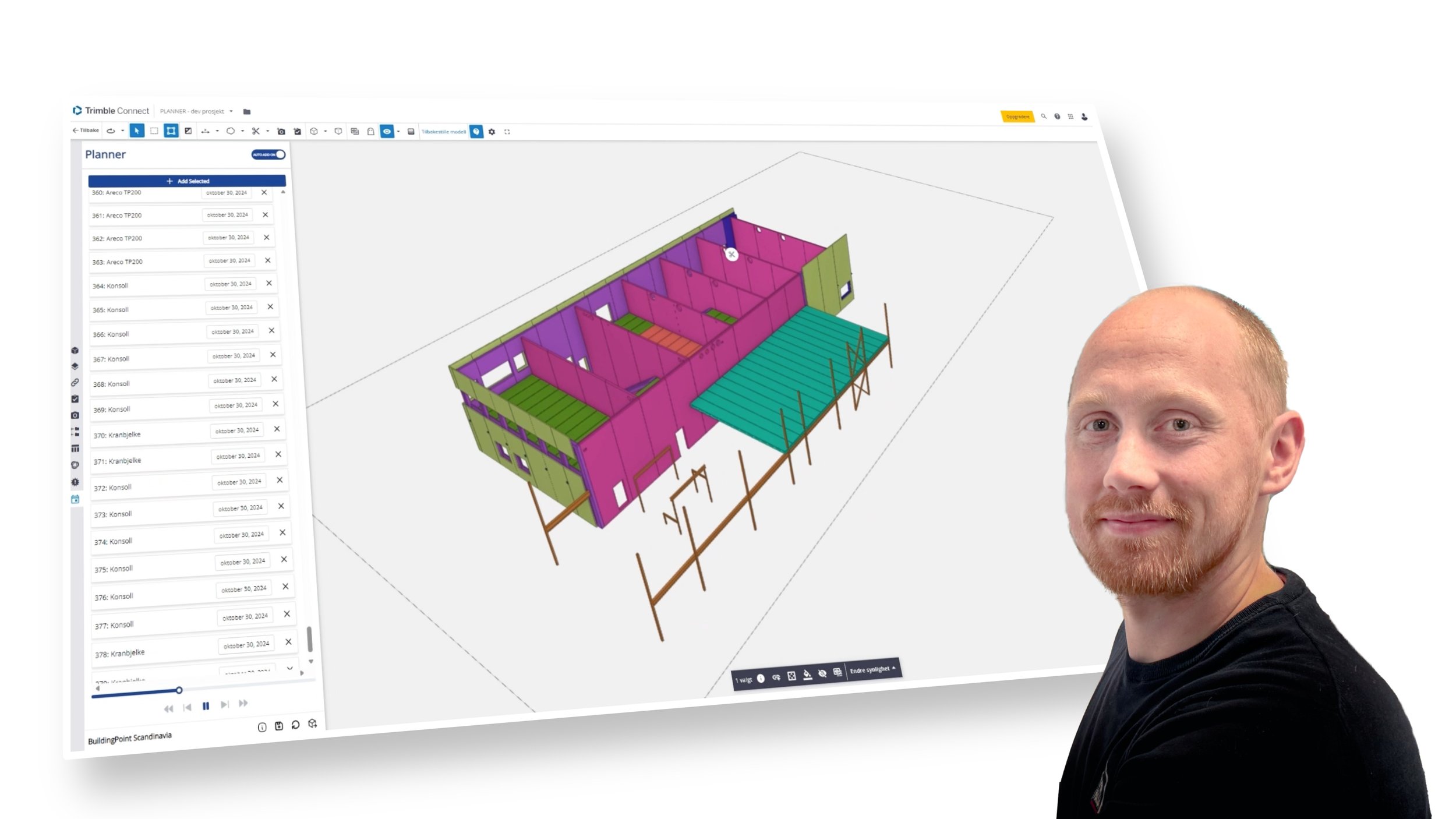

Overhalla Betongbygg

Learn about how Overhalla Betongbygg’s projects went from hundreds to thousands of prefabricated concrete elements, and how the Trimble Connect Planner Extension helps them more work efficiently!

Topics we covered

The agenda topics were focused on practical, 3D model-based workflows that support the full precast process—from early planning through to production and erection.

✔ Life Cycle Assessment (LCA) in Early Design - See how environmental data can be included at early stages to support sustainability goals and client requirements—without adding extra workload.

✔ Precast Sandwich Elements with Integrated Facades - Learn how teams are planning, detailing, and coordinating complex assemblies—such as walls with built-in windows and brickwork—using accurate, data-rich 3D models.

✔ AI-assisted Drawing Tools - Explore how automation in drawing production reduces manual work, increases quality, and ensures alignment between models and documentation.

✔ Project examples from the industry from Spæncom, Industri Beton and Concribe!

Want to learn more about how we have helped the Precast Concrete industry with BIM for decades?

Contact Marcus Rodriguez—himself a former precast engineer—for a quick chat! Or contact us here:

OTHER ARTICLES